An entrepreneur identifies what seems like a perfect industrial site in Belgium: competitively priced, with ample space and good transport links. The deal seems straightforward, but six months later, the project is stalled. The local power grid cannot supply the required electricity, and an upgrade will take over 18 months and cost millions of euros.

This scenario is an all-too-common one, highlighting a major hurdle for new industrial projects in highly developed regions like Belgium. While the country offers a prime location in the heart of Europe, securing a suitable site involves much more than simply acquiring land.

The real challenge lies in navigating zoning regulations and, most importantly, securing utility connections.

This guide explains how to identify suitable industrial land in Belgium and secure the power, water, and gas connections essential for a manufacturing facility.

Table of Contents

Understanding the Belgian Industrial Landscape

Belgium is a federal state with three regions, each with its own economic development agency and specific regulations:

- Flanders (North): Supported by Flanders Investment & Trade (FIT) and VLAIO. The region is economically dense, and industrial land is scarce.

- Wallonia (South): Supported by the Wallonia Export-Investment Agency (AWEX). This region often has more available land compared to Flanders.

- Brussels-Capital Region: Supported by hub.brussels, focusing primarily on urban and service-based industries.

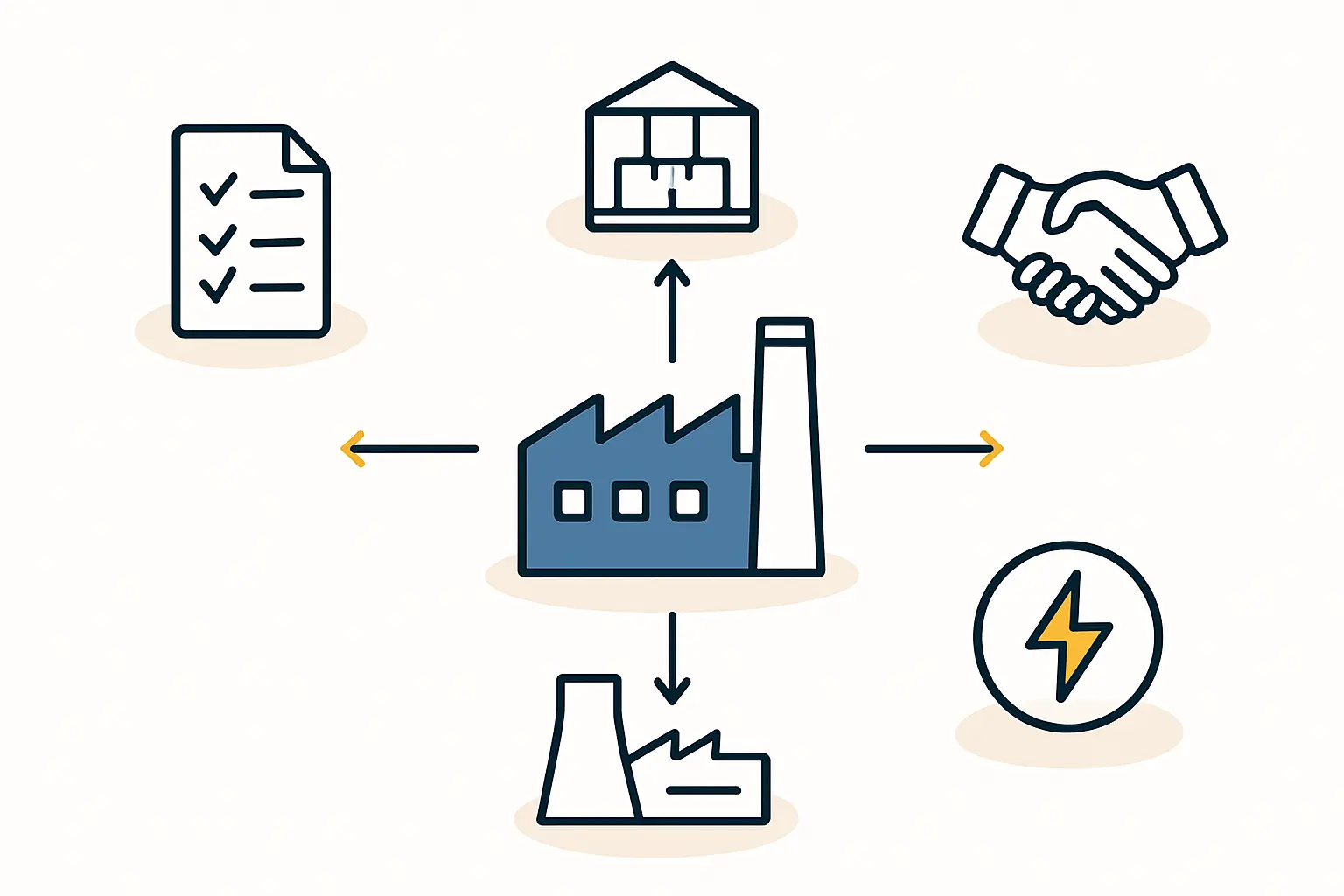

The search for a site typically reveals two main categories:

- Greenfield Sites: Undeveloped land, often agricultural, that must be rezoned for industrial use. This process can be lengthy and complex.

- Brownfield Sites: Previously used industrial land that is being redeveloped. Due to land scarcity, particularly in Flanders, brownfield projects are often encouraged and may come with specific incentives.

However, the most critical factor is not the land itself, but its underlying infrastructure.

The Decisive Factor: Utility Connections for Manufacturing

For an energy-intensive operation like solar module manufacturing, the availability and cost of utilities are paramount. A seemingly affordable plot of land is worthless if it cannot be adequately serviced.

The Electricity Challenge: Powering Your Operations

Securing a high-voltage electricity connection is the single greatest challenge for new industrial projects in Belgium, especially in Flanders, where the grid is often congested.

A semi-automated solar module factory requires a significant and stable power supply, often in the range of 2 to 5 megavolt-amperes (MVA). Establishing a new connection of this magnitude is a complex undertaking.

Based on data from recent industrial projects, you should anticipate:

- A timeline of 18 to 24 months from the initial request to the final connection.

- Costs that can easily run into the millions of euros, covering substations, transformers, and grid reinforcement.

This long lead time means the power connection application must be one of the very first steps in your project plan—often initiated even before the final property purchase.

Water Supply and Discharge Considerations

Compared to electricity, securing a water connection is generally more straightforward but still requires careful planning. Planners must account for the difference between:

- Domestic Water: For sanitary facilities and offices.

- Process Water: For manufacturing processes, which may have specific purity requirements.

Strict regulations also govern the discharge of industrial wastewater, requiring separate environmental permits that specify the water’s volume and chemical composition.

Natural Gas Availability

The availability of a natural gas connection varies by location. While many industrial parks are equipped with gas lines, this is not guaranteed. For processes that rely on gas for heating, confirming its availability should be an early step in the site selection process.

A Step-by-Step Approach to Site Selection

A structured approach can help mitigate the risks of site selection and securing utilities.

- Define Technical Requirements: Before beginning your search, clearly define the factory’s needs: total land area, required building height, floor load capacity, and, most importantly, precise utility requirements (MVA for electricity, cubic meters per hour for water).

- Engage with Regional Development Agencies: Contacting VLAIO in Flanders or AWEX in Wallonia is a crucial step. These agencies maintain databases of available industrial sites and can provide initial information on utility availability in specific zones.

- Conduct Thorough Due Diligence: Once a potential site is identified, a detailed investigation is essential. This goes beyond a simple site visit; you must understand the zoning plan in detail, confirm what type of industrial activity is permitted, and analyze the building requirements for your specific machinery. The way you plan your solar module factory layout will directly influence the type of building you need.

- Initiate Utility Connection Requests: As soon as a site is shortlisted, submit formal inquiries to utility providers (e.g., Elia for high-voltage electricity, local providers for water and gas). Their binding feedback will determine the site’s true viability.

Common Pitfalls to Avoid

Drawing on the experience of J.v.G. Technology GmbH in setting up turnkey factories, several common mistakes can delay or even derail a project:

- Underestimating Utility Timelines and Costs: The 18-24 month lead time for a power connection is not an exaggeration. A realistic business plan must factor this into the project timeline from day one.

- Assuming “Industrial Zone” is Sufficient: Not all land zoned for “industrial” use is suitable for heavy manufacturing. Some zones may be restricted to logistics or light assembly and lack sufficient power infrastructure.

- Neglecting Local Logistics: Evaluate access roads for heavy transport, proximity to major highways and ports, and the local labor market.

A successful site selection process is a project in itself, requiring meticulous planning and early engagement with all relevant authorities and utility providers. By treating utility connections as a primary decision factor rather than an afterthought, an entrepreneur can lay a solid foundation for their manufacturing venture in Belgium.

Frequently Asked Questions (FAQ)

Q: Why is securing an electricity connection so difficult in Belgium?

A: The difficulty comes down to high demand and an aging grid that is often operating at full capacity, particularly in the densely populated region of Flanders. The transition to renewable energy also places new demands on the grid. Upgrading the infrastructure to accommodate a new, large industrial consumer is a complex and time-consuming engineering project.

Q: What is the main difference between a greenfield and a brownfield site?

A: A greenfield site is undeveloped land, meaning all infrastructure (roads, utilities, buildings) must be built from scratch. A brownfield site has been previously developed for industrial use. While it may require demolition or remediation, it often benefits from existing infrastructure connections and zoning approvals, which can accelerate a project.

Q: Realistically, how long does the entire process take, from site search to an operational factory?

A: For a new industrial project in Belgium, a realistic timeline is approximately two to three years. This includes about 6-12 months for site selection and due diligence, followed by 18-24 months for permitting, construction, and securing the high-voltage power connection.

Q: Can pvknowhow.com or J.v.G. assist with site selection in Belgium?

A: Yes. As part of its turnkey factory solutions, J.v.G. Technology GmbH provides comprehensive site selection services. This includes drawing on its network of local partners, engaging with regional development agencies, and managing the technical due diligence for utility connections to ensure the chosen site is fully viable for a solar module factory.

Understanding the intricacies of site selection is a fundamental first step. For a complete overview of launching a manufacturing business, the comprehensive guide on how to start a solar module factory provides a structured overview of the entire process.