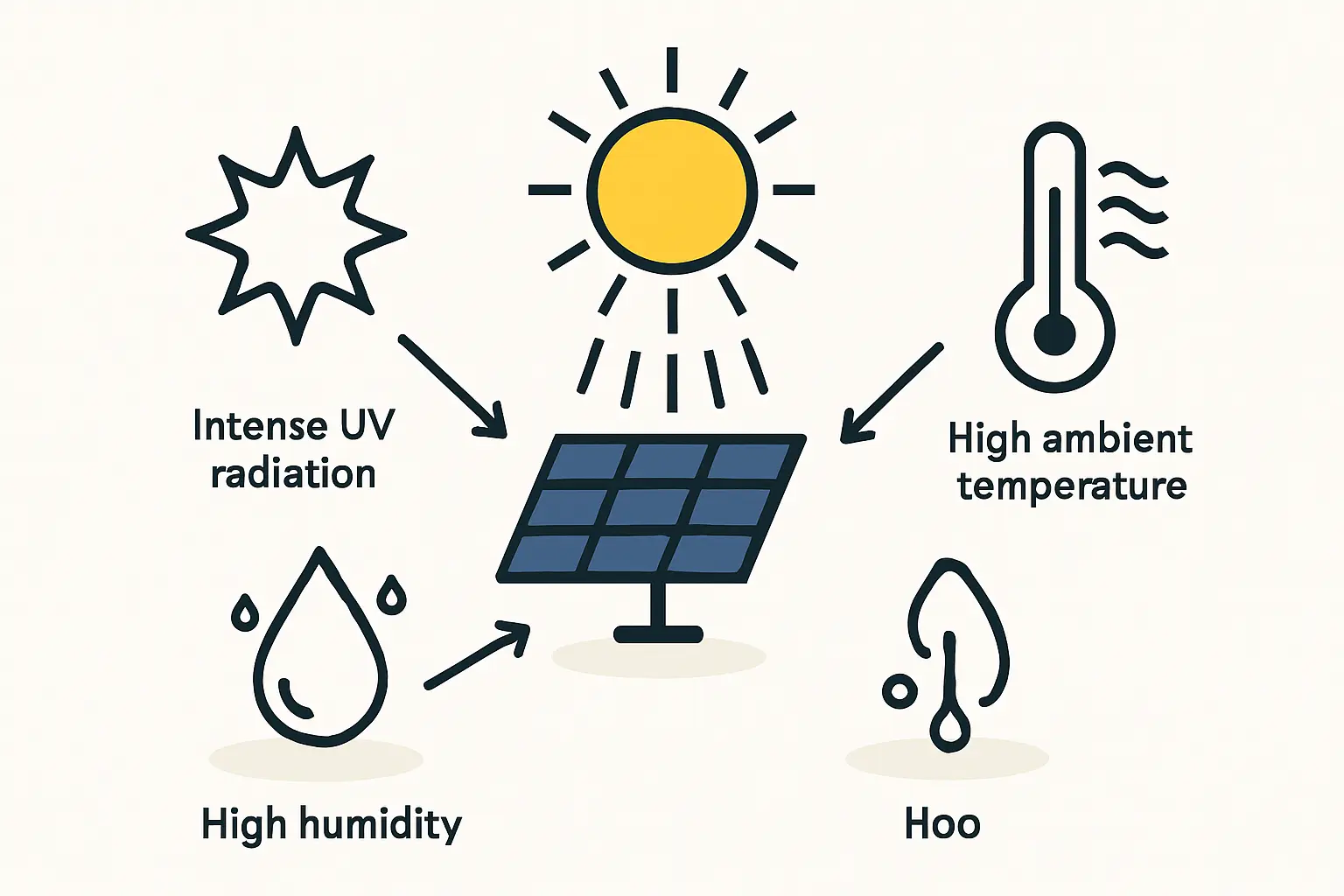

Brunei Darussalam’s commitment to increasing renewable energy to at least 30% of its total power generation capacity by 2035 presents a significant opportunity for local industrial development. However, the very climate that makes the nation ideal for solar power—high heat, intense sunlight, and persistent humidity—also poses a formidable challenge to the long-term performance and durability of solar photovoltaic (PV) modules.

Standard solar modules, often designed for temperate climates, can degrade rapidly in such tropical environments. For entrepreneurs entering this sector, understanding these technical challenges is crucial for building a successful and sustainable manufacturing business. Launching a solar panel company in a market like Brunei requires a specialized approach that prioritizes durability from the very first design decision.

Table of Contents

The Climatic Challenge: Why Standard Solar Modules Underperform in Brunei

A solar module is a highly engineered product designed to last for 25 to 30 years. In Brunei, it must withstand a combination of environmental stressors that can compromise its materials and electrical integrity.

High Humidity (75-80% Average)

Persistent humidity is the most critical factor. Ambient moisture continually seeks to penetrate a module’s protective layers. Over time, this ingress can lead to several severe failure mechanisms:

- Corrosion: Moisture that reaches the metallic contacts and busbars on solar cells can cause corrosion, interrupting the flow of electricity and reducing power output.

- Delamination: The layers of the module—glass, encapsulant, cells, and backsheet—can begin to separate. This creates pathways for more moisture to enter and compromises the module’s structural integrity.

- Potential-Induced Degradation (PID): A serious issue where voltage differences, exacerbated by moisture, create leakage currents that can drastically reduce a module’s power output, sometimes by over 30%.

High Ambient Temperatures (24-32°C)

While solar panels need sunlight, excessive heat reduces their efficiency. For every degree Celsius above the standard test condition of 25°C, a typical module loses a small percentage of its power output. Sustained high temperatures also accelerate the chemical breakdown of a module’s materials, such as the encapsulant and backsheet.

Intense UV Radiation

The strong equatorial sun bombards modules with high levels of ultraviolet (UV) radiation. Over the years, this UV exposure can cause polymers, particularly in the backsheet and standard encapsulants, to become brittle, crack, or turn yellow. This discoloration reduces the amount of light reaching the solar cells, lowering energy production.

Key Material and Design Choices for a Brunei-Focused Production Line

To build a PV module that can reliably perform for decades in Brunei’s climate, a manufacturer must select materials and designs specifically engineered to combat moisture and heat. This approach moves beyond standard industry practice to high-performance, climate-specific engineering.

The Critical Role of the Encapsulant: POE vs. EVA

The encapsulant is the polymer material that bonds the solar cells between the front glass and the rear backsheet, providing electrical insulation and mechanical support.

- Standard Ethylene Vinyl Acetate (EVA): For many years, EVA has been the industry-standard encapsulant. In high-humidity and high-heat conditions, however, it is susceptible to hydrolysis—a chemical breakdown caused by water. This process can release acetic acid, which actively corrodes the delicate silver contacts on solar cells and leads to irreversible power loss.

- Advanced Polyolefin Elastomer (POE): POE is a superior encapsulant for tropical climates. Its primary advantage is an extremely low Water Vapour Transmission Rate (WVTR), making it far more resistant to moisture penetration than EVA. Its stable chemical structure also provides excellent resistance to PID and degradation from UV exposure.

For a manufacturing line in Brunei, selecting POE is a critical decision to ensure the long-term bankability and performance of the final product. While the material cost is higher, the protection it offers is essential.

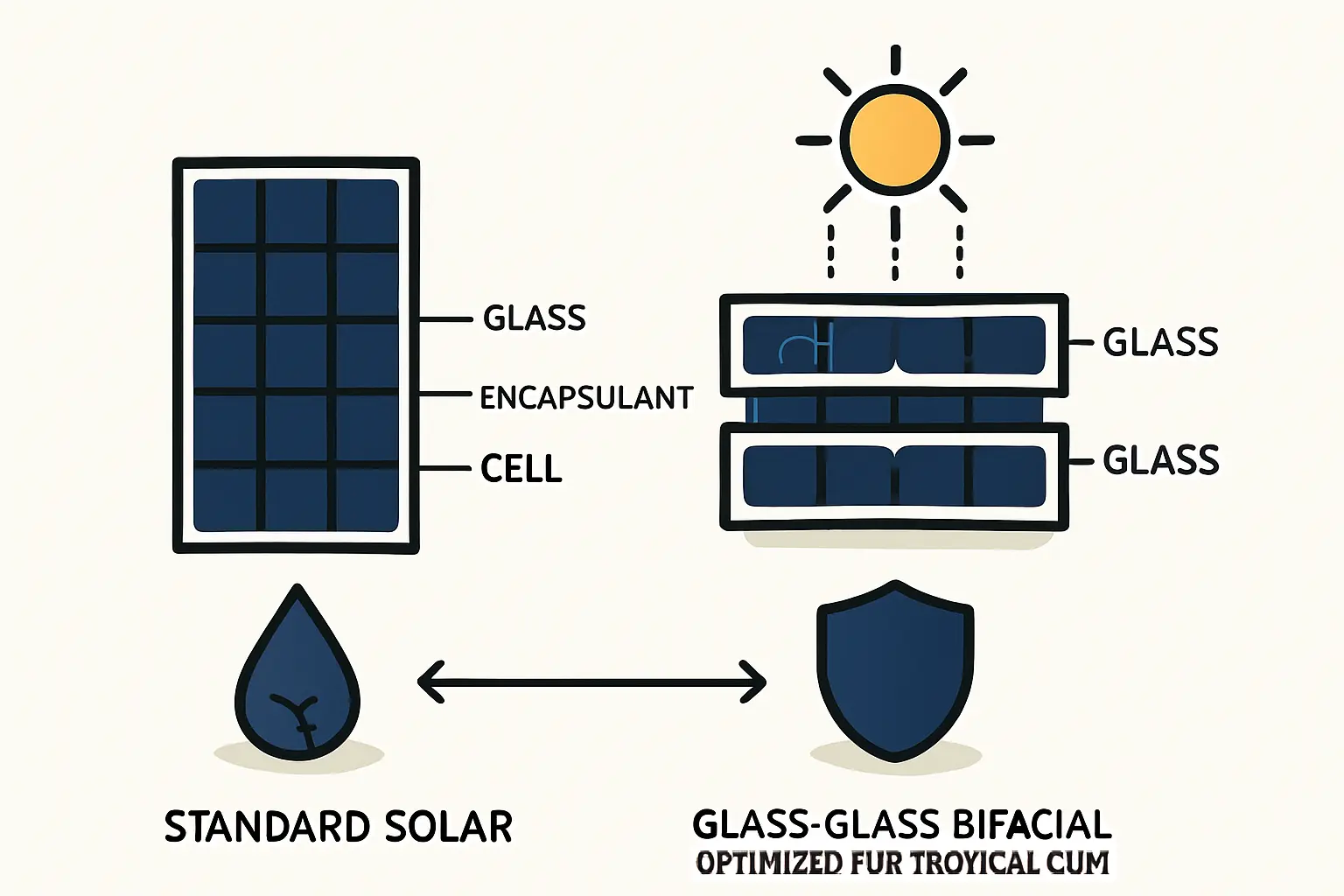

Backsheet vs. Glass-Glass: Securing the Module’s Core

The back layer of a solar panel is its ultimate defence against the elements.

- Polymer Backsheet: A standard module uses a multi-layered polymer backsheet. While effective in moderate climates, lower-quality backsheets can degrade under tropical UV and humidity, becoming porous and allowing moisture ingress over time.

- Glass-Glass (GG) Construction: A far more robust solution is the Glass-Glass design, which replaces the polymer backsheet with a second pane of heat-strengthened glass. By creating a hermetic seal around the solar cells, this design offers the best possible protection against moisture, is inherently PID-resistant, and is exceptionally durable.

Sealing the Deal: Junction Boxes and Edge Sealants

Even with the best core materials, moisture can still find its way in through the module’s edges or connection points.

- Junction Box: This component, which houses the module’s electrical connections, must have a high ingress protection (IP) rating, such as IP67 or IP68, to ensure a complete seal against dust and water.

- Edge Sealant: Using a high-grade butyl or silicone sealant around the perimeter of the laminate provides a final barrier, preventing moisture from creeping in from the sides.

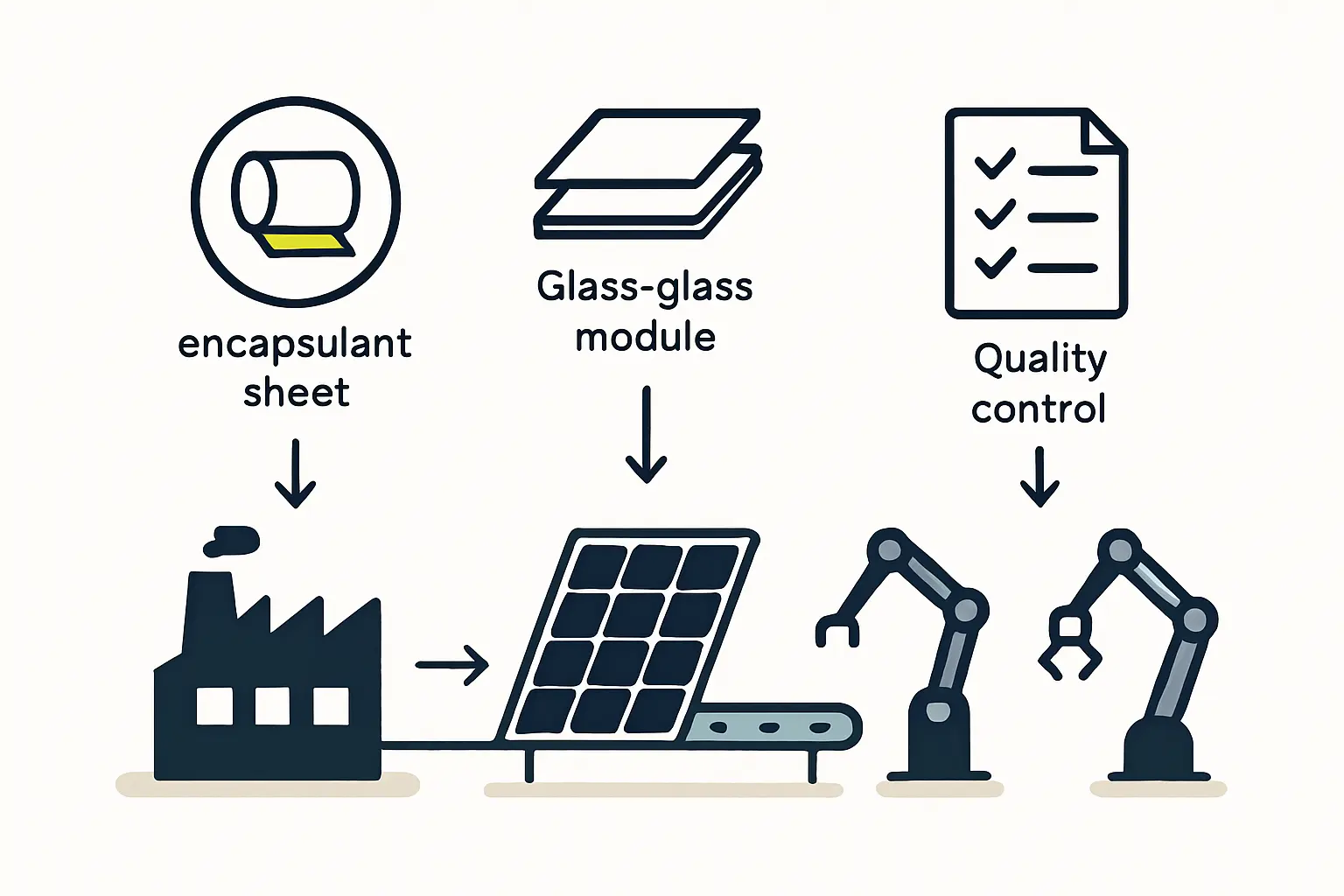

Manufacturing Process Adjustments for Tropical Durability

Specifying the right materials is only half the battle. The quality of the manufacturing process is what transforms those components into a reliable, long-lasting asset. Precision throughout the production line is non-negotiable.

The lamination stage, where the module’s layers are fused together under heat and pressure, is particularly critical. Incorrect temperature, pressure, or timing can lead to improper curing of the POE encapsulant, creating microscopic voids or weaknesses that humidity will exploit over the module’s lifetime.

Stringent quality control, including high-resolution electroluminescence (EL) testing, is also vital. This process can detect invisible microcracks in the solar cells. In a humid environment, these cracks become entry points for moisture that can lead to premature failure. While investing in high-performance materials and advanced quality control increases the initial manufacturing plant cost, it is a crucial investment in creating a product that can be confidently warranted for 25+ years in a tropical climate.

The Business Case for Climate-Specific Manufacturing

Producing modules engineered specifically for Brunei’s climate is not just a technical requirement—it’s a powerful business strategy. A locally manufactured, ‘Brunei-proof’ solar panel offers significant competitive advantages:

- Higher Bankability: Projects using these modules will demonstrate lower degradation rates and higher long-term energy yields, making them more attractive to investors and financial institutions.

- Stronger Brand Reputation: A manufacturer that can prove its products outperform standard imports will build a reputation for quality and reliability.

- Reduced Warranty Claims: Building a durable product from the outset minimizes the financial risk associated with future warranty and replacement costs.

Based on experience from J.v.G. turnkey projects in similar climates, this focus on technical excellence is what separates a short-lived venture from a long-term industrial asset.

Frequently Asked Questions (FAQ)

Q: Are these specialized modules much more expensive to produce?

A: While the upfront material and equipment costs are moderately higher, the true cost of solar power is measured by its Levelized Cost of Energy (LCOE). Because these modules produce more power over a longer lifespan with less degradation, they deliver a lower LCOE and a superior long-term financial return for the end customer.

Q: Can a new factory in Brunei source these advanced materials like POE?

A: Yes. The global supply chains for high-performance materials like POE encapsulants and high-quality glass are well-established. A key service provided by a turnkey line provider is establishing and qualifying these supply chains during the initial factory setup.

Q: Is a Glass-Glass module heavier than a standard module?

A: Yes, a Glass-Glass module is slightly heavier because it replaces the lightweight polymer backsheet with glass. This is a standard consideration that engineers easily manage when designing the mounting structures for solar projects.

Q: How does PID affect a solar plant’s financial performance?

A: Potential-Induced Degradation can cause a power loss of 10% to 30% or more within a few years. For a commercial-scale solar plant, this translates directly into a significant loss of revenue and can severely impact the project’s return on investment. Preventing PID through proper material selection is one of the most crucial financial safeguards in module design.

Conclusion: Building for Longevity

Successfully entering the solar manufacturing market in Brunei requires more than assembling standard components. It demands an engineering-first approach that directly confronts the challenges posed by a tropical, high-humidity environment.

By making informed decisions on critical materials like POE encapsulants and adopting advanced designs such as Glass-Glass construction, a new enterprise can produce modules offering superior durability, performance, and long-term value. This commitment to quality is the foundation for building a respected brand and a profitable business capable of supporting Brunei’s renewable energy ambitions for decades to come.