Setting up a solar module factory is a significant undertaking that demands complex machinery, precise engineering, and a skilled workforce. For a project in a landlocked nation like Burkina Faso, however, one of the most critical challenges emerges long before the first machine is ever installed.

The success of the entire venture can hinge on a seemingly straightforward task: moving equipment from a distant seaport to the final factory site. An entrepreneur might focus intensely on the specifications of a solar laminator or a cell stringer, only to find the project delayed by weeks or months because a container is held up at a border crossing hundreds of kilometers away.

This guide offers a strategic framework for navigating the logistical complexities of establishing a solar factory in Burkina Faso, focusing on the crucial decisions of port selection and inland transport.

Table of Contents

The Landlocked Challenge: Why Logistics Can Define Project Success

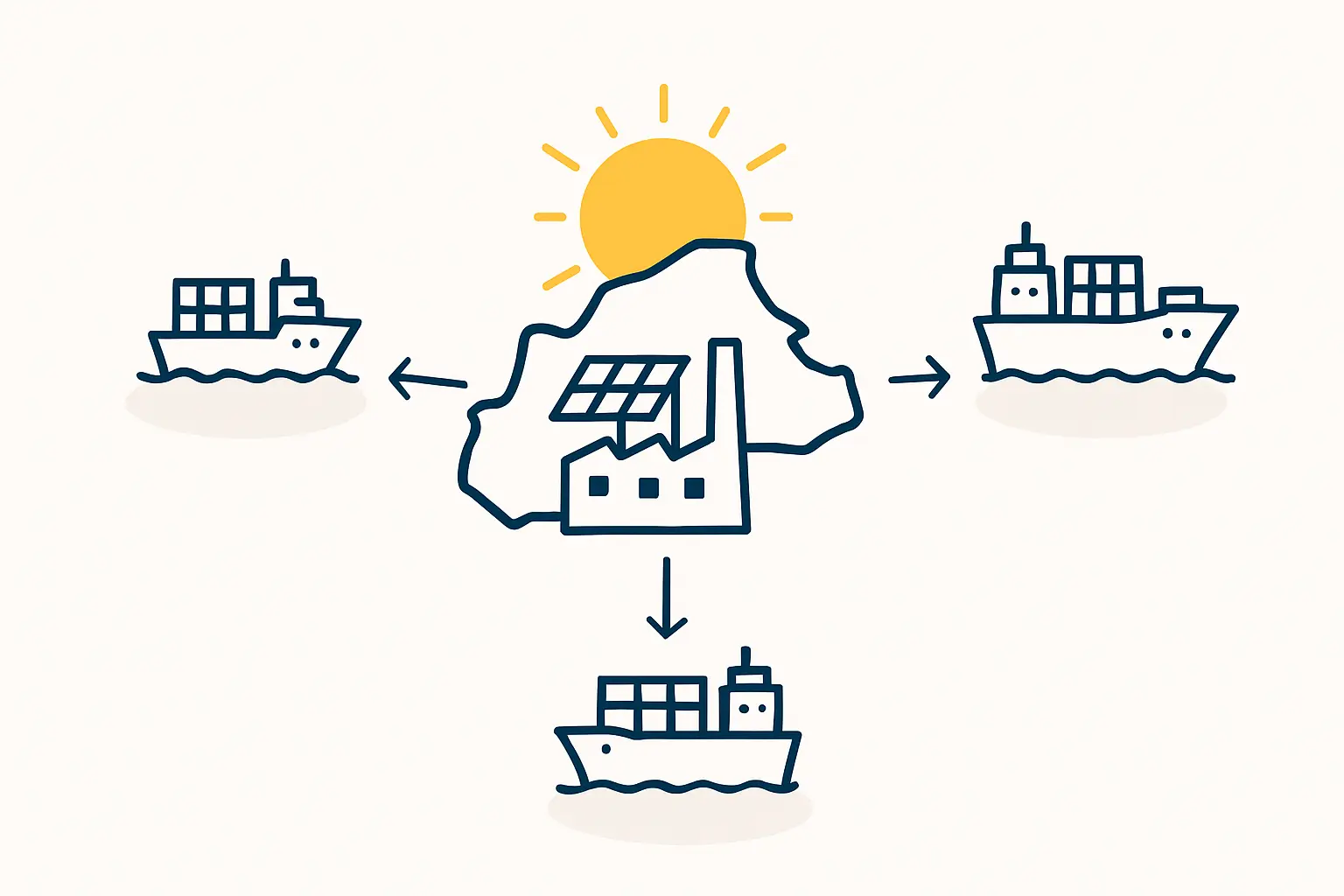

Logistics are a major cost for any manufacturing project, but for a solar factory in Burkina Faso, they become a primary strategic consideration. The country relies on the ports and infrastructure of its coastal neighbors—primarily Ghana, Togo, and Côte d’Ivoire—to import essential solar module manufacturing equipment.

Experience from industrial projects in the region reveals that logistics and transport costs can account for 15% to 20% of the total initial capital expenditure. This is a substantial figure that can derail financial models if not forecasted accurately.

The journey from a Burkina Faso sea port to a factory in Ouagadougou or Bobo-Dioulasso isn’t merely a matter of distance. It’s a complex process involving port authorities, customs agencies, freight forwarders, and variable road conditions. A well-planned logistics strategy is fundamental to keeping the project on budget and on schedule.

Evaluating the Key Maritime Gateways to Burkina Faso

The choice of seaport is the first and most consequential decision in the logistics chain. Each port offers a unique combination of efficiency, cost, distance, and risk. Three primary ports serve as the main gateways for cargo destined for Burkina Faso.

Port of Tema, Ghana

Located approximately 950 kilometers from Ouagadougou, the Port of Tema is one of West Africa’s most modern and efficient container terminals.

Key advantages include its advanced infrastructure, streamlined customs, and a reputation for reliability. The transport corridor from Tema to Ouagadougou is well-established, benefiting from Ghana’s relative political stability and well-maintained primary road network.

However, the longer distance can translate to higher inland freight costs compared to closer alternatives. Port handling charges may also be higher, reflecting the premium infrastructure.

This port is an excellent choice for investors who prioritize predictability and risk mitigation. For high-value, sensitive equipment, the reliability of the Tema corridor often justifies the additional cost.

Port of Lomé, Togo

Roughly 750-800 kilometers from Ouagadougou, the Port of Lomé is often the closest geographical option.

Its primary advantage is the shorter distance, which can lead to faster transit times and potentially lower freight costs. The port has also made significant investments to position itself as a key regional transshipment hub.

On the other hand, customs and administrative processes can sometimes be less predictable than in Tema. The quality of the road infrastructure along the entire route also requires careful assessment.

Lomé is a strong option for projects where speed of delivery is a critical factor. Success on this route hinges on partnering with a highly experienced local logistics agent who can navigate its specific operational nuances.

Port of Abidjan, Côte d’Ivoire

As one of the largest ports in the region, Abidjan offers extensive shipping services and has deep historical and economic links with Burkina Faso, including a direct railway line.

A key advantage is the wide range of shipping lines and logistics providers operating out of Abidjan. The shared currency (CFA Franc) can also simplify some financial transactions.

A key consideration is that its road and rail corridors have historically faced periods of disruption. Current security conditions along the transport route must be thoroughly evaluated as part of the risk assessment when conducting a feasibility study.

This option is best for entrepreneurs who may already have established business operations or logistical networks within Côte d’Ivoire.

Key Decision Factors for Port and Route Selection

Choosing between these ports requires an analysis that goes beyond a simple comparison of shipping quotes.

Total Landed Cost Analysis

The “cheapest” port isn’t always the one with the lowest freight rate. A comprehensive analysis must include ocean freight, port handling fees, customs duties, inland transport, insurance, and a contingency for potential demurrage from delays. This holistic view provides a true picture of each option’s financial impact.

Infrastructure and Road Conditions

The condition of the roads directly impacts transit time, the risk of damage to sensitive equipment, and insurance costs. Seasonal factors, such as the rainy season (typically May to September), can make certain routes difficult or impassable for heavy vehicles, causing significant delays.

Customs and Border Crossing Efficiency

Delays at border crossings are a common bottleneck. The efficiency of customs clearance depends on correct documentation, harmonized regulations between countries, and the expertise of your customs broker. Minor errors in paperwork for high-value machinery can lead to costly and time-consuming disputes.

Security and Political Stability

The security situation along the transport corridor is a critical concern. A thorough risk assessment is essential, considering the stability of the transit country and the security of the specific route. This assessment will also influence the cost and availability of comprehensive cargo insurance.

From Port to Plant: Managing Inland Transportation

Once the containers are cleared from the port, the final leg of the journey begins. This phase requires meticulous on-the-ground management.

Selecting a Reliable Freight Forwarder

Engaging in expert freight forwarding for Burkina Faso is not an area for cost-cutting. The ideal partner will have proven experience with the specific port and land corridor, clearing industrial machinery, managing border crossings, and providing real-time tracking and communication.

Insurance: A Non-Negotiable Requirement

Comprehensive “warehouse-to-warehouse” cargo insurance is essential. It must cover all potential risks, including damage, theft, and loss, from the moment the equipment leaves the manufacturer’s facility until it is safely delivered and unloaded at the factory site.

Final Site Logistics

Logistical planning doesn’t end when the truck arrives at the factory gate. The site must be fully prepared, with all-weather access roads capable of supporting heavy trucks and the necessary cranes and forklifts on hand to safely unload the equipment.

A Practical Perspective: Insights from J.v.G. Projects

Experience from J.v.G. Technology GmbH’s turnkey projects in emerging markets reveals a common oversight: underestimating the time and cost buffers needed for inland transit. A journey that appears to be two days on a map can easily stretch to over a week due to an unexpected customs inspection, a mechanical breakdown on a remote road, or a national holiday.

A prudent approach involves building a contingency of at least 15-20% into both the logistics budget and the project timeline. This buffer accounts for the unpredictable realities of cross-border transport in the region and transforms a potential crisis into a manageable variable.

Frequently Asked Questions (FAQ)

Q: Which port is definitively the “best” for Burkina Faso?

A: There is no single “best” port—only the most suitable one for a specific project’s priorities. The optimal choice is a trade-off between cost, speed, and risk. The Port of Tema in Ghana generally offers the highest reliability, while the Port of Lomé in Togo may provide a faster, more cost-effective route, albeit with potentially higher variability.

Q: How long does inland transport from the port to Ouagadougou typically take?

A: While the net driving time might be two to three days, the complete process from the ship’s arrival at port to final delivery at the factory can realistically take between one and three weeks. This extended timeframe accounts for vessel unloading, port clearance, customs procedures, and potential delays during the inland journey.

Q: Is rail transport a viable alternative to trucks?

A: The railway connecting Abidjan to Ouagadougou is a long-standing line. However, its current operational efficiency, reliability, and capacity for transporting oversized or sensitive industrial equipment must be carefully verified during the planning phase. For most projects, road freight remains the more common, flexible, and predictable solution.

Conclusion and Next Steps

For entrepreneurs venturing into solar manufacturing in Burkina Faso, mastering logistics is as crucial as mastering the technology itself. The selection of a seaport and the planning of inland transport are not administrative afterthoughts; they are foundational strategic decisions that directly influence project costs, timelines, and overall risk.

By carefully analyzing the trade-offs between the key port gateways and partnering with experienced local logistics experts, you can build a resilient supply chain that ensures your state-of-the-art equipment arrives safely and on schedule. This deliberate, informed approach to logistics paves the way for a successful factory launch and a sustainable manufacturing operation.