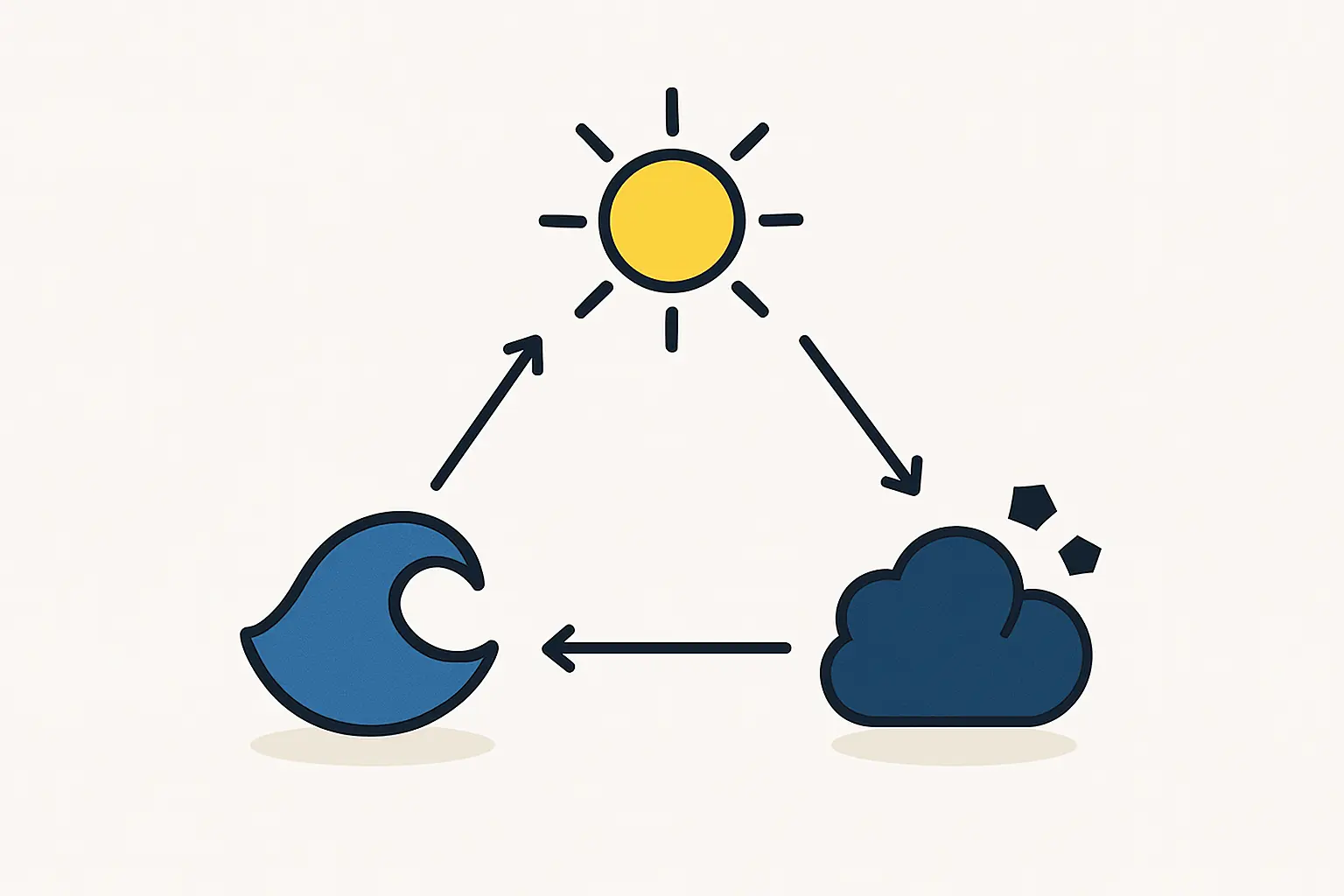

An investor standing on the coast of Cabo Verde sees two powerful, abundant resources: constant sunshine and a vast ocean. The potential for solar energy seems self-evident. Yet the very sea breeze that cools the islands carries a hidden threat to solar investments: a highly corrosive mixture of salt and moisture that can cripple standard solar modules in a fraction of their expected lifespan.

Choosing the right solar panel technology is not merely a matter of efficiency or price; in a maritime environment like Cabo Verde’s, it is the primary factor determining a project’s long-term viability and profitability. This article examines the region’s specific environmental challenges—salt mist corrosion and intense ultraviolet (UV) radiation—and details the optimal module designs and material choices for building durable, high-performance solar assets.

Table of Contents

The Dual Challenge: High UV Radiation and Aggressive Salt Mist

The climate of Cabo Verde presents a combination of factors particularly harsh on the materials in conventional solar modules. Understanding these stressors is the first step toward selecting technology that can withstand them.

The Impact of Salt Mist Corrosion

Salt mist consists of fine aerosol particles of salt and water carried inland by ocean winds. When this mist settles on solar installations, it initiates several destructive processes:

- Frame and Component Corrosion: Salt accelerates the oxidation of metal components, particularly aluminum frames and mounting structures. Over time, this can compromise the structural integrity of the entire array.

- Junction Box Failure: Moisture and salt can penetrate the junction box—the electrical heart of the module—causing corrosion of terminals, short circuits, and eventual failure.

- Surface Contamination: Salt deposits attract dust and grime, forming a hard-to-clean layer that reduces the amount of light reaching the solar cells, lowering energy output.

- Potential-Induced Degradation (PID): The presence of sodium ions from the salt, combined with high humidity and voltage, can accelerate a phenomenon known as PID, which dramatically reduces a module’s power output.

The Effect of Intense UV Radiation

Located near the equator, Cabo Verde experiences high levels of UV radiation year-round. While beneficial for energy generation, this intense sunlight relentlessly attacks the polymeric materials used in many solar modules, primarily the backsheet.

Over time, UV exposure causes these materials to become brittle, crack, or delaminate. This degradation exposes the sensitive inner layers of the module to the elements, leading to moisture ingress and rapid failure, especially when combined with corrosive salt air.

Module Construction: Glass-Glass vs. Glass-Backsheet

The physical construction of a solar module is its first line of defense against harsh environmental conditions. The two dominant designs on the market offer vastly different levels of protection.

The Conventional Approach: Glass-Backsheet Modules

A standard solar module consists of a top layer of glass, an encapsulant material (typically EVA), solar cells, another layer of encapsulant, and a final protective polymer backsheet. While cost-effective and suitable for many climates, this design reveals a critical vulnerability in a maritime environment.

The polymer backsheet is susceptible to degradation from both UV radiation and physical damage, and it is not completely impermeable to moisture. Over years of exposure, water vapor can slowly penetrate, leading to internal corrosion and delamination.

The Superior Solution: Glass-Glass (Bifacial) Modules

A more robust alternative is the glass-glass module design. In this construction, the polymer backsheet is replaced with a second layer of heat-strengthened glass. This creates a hermetically sealed, sandwich-like structure that is exceptionally resilient.

The key advantages for an environment like Cabo Verde include:

- Impermeability: Glass is impervious to moisture and salt, preventing water vapor from reaching the solar cells and internal wiring.

- UV Resistance: Glass is highly stable under UV radiation and does not degrade, yellow, or become brittle over time.

- Mechanical Strength: The dual-glass structure provides superior mechanical stability, protecting the cells from stress and reducing the risk of microcracks.

- Longevity: Due to their enhanced durability, glass-glass modules typically come with longer warranties and exhibit lower annual degradation rates, ensuring a more stable return on investment.

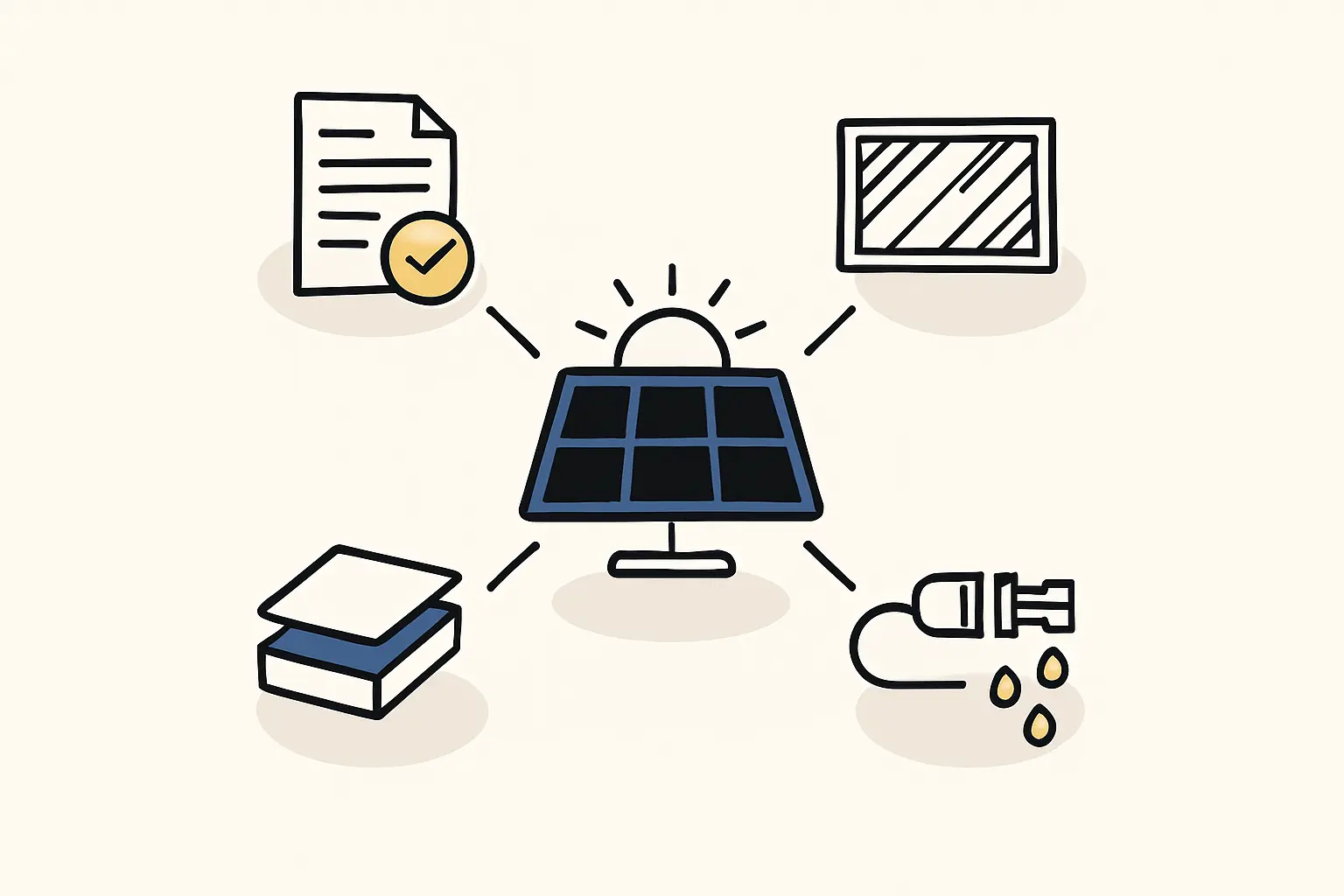

Key Components and Their Resistance to Harsh Conditions

Beyond the primary structure, the choice of internal components is critical for a solar module’s longevity in a corrosive environment.

Encapsulants: EVA vs. POE

The encapsulant is the adhesive polymer that bonds the layers of the module together and protects the solar cells. For decades, Ethylene Vinyl Acetate (EVA) has been the industry standard. However, a newer material, Polyolefin Elastomer (POE), offers significant advantages in hot, humid climates.

POE has a much lower water vapor transmission rate (WVTR) than EVA, providing a superior barrier against moisture ingress. It is also inherently more resistant to PID. For projects in coastal locations like Cabo Verde, specifying modules with a POE encapsulant adds a critical layer of long-term protection.

Frames and Junction Boxes

Even with a robust glass-glass design, peripheral components must be chosen carefully. The aluminum frame should be made from a corrosion-resistant alloy with a thick, high-quality anodized coating to withstand salt spray, as standard frames can show significant corrosion in just a few years.

Likewise, the junction box must have a high Ingress Protection (IP) rating, ideally IP68, to ensure it is fully sealed against both dust and prolonged water immersion. This prevents the corrosive failure of electrical connections.

The Importance of IEC Salt Mist Corrosion Testing

To verify a module’s suitability for a maritime environment, investors should look for certification to the International Electrotechnical Commission (IEC) 61701 standard for salt mist corrosion testing. This test exposes modules to a concentrated salt spray for an extended period to simulate years of coastal exposure.

The standard has several severity levels. For locations like Cabo Verde, specifying modules certified to at least Severity Level 6 is a prudent measure to de-risk the investment and ensure the asset will perform reliably for its entire projected lifespan. Based on experience from J.v.G. turnkey projects in similar environments, this certification is a non-negotiable requirement for long-term project success.

Balancing Initial Investment with Long-Term Returns

Modules built with glass-glass construction, POE encapsulant, and certified corrosion resistance typically have a higher purchase price than standard glass-backsheet modules. However, the decision should be based on the Levelized Cost of Energy (LCOE) and the total cost of ownership over the project’s 25- to 30-year life.

A standard module might degrade at 0.7% annually, while a high-quality glass-glass module may degrade at only 0.45%. This difference in performance compounds year after year, resulting in significantly higher energy generation and revenue. The higher upfront cost is an insurance policy against premature failure, costly replacements, and lost production, making it a sounder long-term investment.

Frequently Asked Questions

Q: What exactly is salt mist corrosion?

A: Salt mist corrosion is the degradation of materials caused by airborne salt particles from the ocean. These particles land on surfaces and, in the presence of moisture, create a highly corrosive electrolyte that attacks metals and can penetrate protective coatings.

Q: Are glass-glass modules much more expensive?

A: They carry a modest premium, typically 5–15% higher than conventional glass-backsheet modules. However, this cost is often offset by their longer lifespan, lower degradation rate, and higher energy yield, leading to a better long-term return on investment.

Q: Can’t you just clean the salt off the modules regularly?

A: While regular cleaning is essential for maintaining performance by removing dust and salt build-up, it does not prevent the underlying corrosion. The corrosive mist can penetrate seals and attack frames and junction boxes—problems that cleaning cannot solve. The damage is slow, steady, and often internal.

Q: What is the typical lifespan of a module in a place like Cabo Verde?

A: A standard, uncertified glass-backsheet module may begin to fail significantly in as little as 5–10 years. A properly specified glass-glass module certified for salt mist corrosion is designed to last for its full warranty period of 25–30 years or more.

Q: How does bifacial technology work in this context?

A: Many glass-glass modules are also bifacial, meaning they can generate power from both sides. This technology is particularly relevant for ground-mounted installations in Cabo Verde, where sunlight reflected from sandy or light-colored ground can be captured by the rear of the module, increasing total energy output by 10-25%. This further improves the project’s economics. For those planning to establish local production, a bifacial solar module production line can be configured to manufacture these advanced modules.

Making an Informed Decision for Your Cabo Verde Project

The sunny, windswept islands of Cabo Verde are an ideal location for solar power generation, but only if the right technology is deployed. The environmental stressors of salt mist and high UV radiation are unforgiving of standard equipment.

For investors and entrepreneurs looking to enter this market, technical specifications are paramount. A robust, long-lasting solar project in this region will be built on glass-glass modules, POE encapsulants, corrosion-resistant components, and stringent IEC 61701 certification. Prioritizing these engineering details during the planning phase is the most effective way to ensure a secure, profitable, and durable energy asset. Understanding these technical requirements is the first step, and resources like the structured e-courses at pvknowhow.com can provide a comprehensive foundation for project planning.