Imagine a state-of-the-art lamination machine, halfway through its critical 20-minute cycle, suddenly losing power. The temperature and pressure drop, ruining an entire batch of nearly finished solar modules. For manufacturers in many regions, this scenario is not a hypothetical risk—it is a daily operational reality. For an aspiring entrepreneur in Cameroon, understanding and solving the energy supply issue is the first and most critical step toward building a successful solar module factory.

The irony is striking: to manufacture a product that provides stable, reliable electricity, one must first have a stable, reliable electricity supply. This article examines the specific power grid challenges in Cameroon and outlines practical, resilient energy solutions that can transform this potential vulnerability into a competitive advantage.

Table of Contents

The Power Paradox in Cameroon’s Manufacturing Sector

Cameroon’s energy landscape presents a significant challenge for any industrial venture. The national grid has an installed capacity of approximately 1,557 MW, which is already stretched thin by a peak demand of around 1,600 MW. With demand projected to more than double to 3,365 MW by 2030, this supply-demand gap is only set to widen.

The heart of the issue lies in the grid’s composition and condition:

- Dependence on Hydropower: Approximately 73.2% of the country’s electricity comes from hydroelectric sources. While renewable, this makes the power supply highly vulnerable to climatic changes, such as seasonal droughts that can severely reduce generation capacity.

- Aging Infrastructure: Underinvestment in transmission and distribution networks leads to frequent technical failures. For businesses, this results in a pattern of unpredictable power outages, brownouts (voltage drops), and power surges that can damage sensitive equipment.

- Geographical Disparities: These issues are often more pronounced outside major urban centers like Douala and Yaoundé, where many industrial sites may be located.

For a manufacturer, this unreliability translates directly into significant business risks, including production stoppages, damaged machinery, and the inability to meet delivery deadlines.

Why Stable Power is Non-Negotiable for Module Production

A solar module assembly line is a series of precise, time-sensitive processes. Unlike some other forms of manufacturing, it cannot simply be paused and restarted without severe consequences.

Impact on Critical Machinery

Several key stages in the production process are acutely sensitive to power interruptions:

- Cell Stringing: Automated stringers solder delicate solar cells together with extreme precision. A sudden shutdown can misalign the ribbons, damage the cells, and require a time-consuming reset and recalibration.

- Lamination: Arguably the most critical step, lamination uses heat and pressure over a set period (typically 15-20 minutes) to bond the glass, encapsulant (EVA), solar cells, and backsheet. An interruption during this cycle can lead to improper curing, causing bubbles, delamination, or other defects that render the entire module useless.

The Financial Consequences of Instability

The direct costs of an unstable power supply are substantial and extend well beyond simple downtime. These include:

- Material Waste: Every failed lamination cycle wastes valuable components, including solar cells, glass, EVA, and backsheets.

- Reduced Throughput: Unplanned stops drastically lower the factory’s output and efficiency, inflating the cost per unit.

- Equipment Damage: Power surges and abrupt shutdowns can harm the sensitive electronics controlling modern manufacturing equipment, leading to expensive repairs and extended downtime.

Ultimately, inconsistent power compromises the quality and bankability of the final product. A module with defects from a faulty production process will fail certification tests and be rejected by the market.

Evaluating Power Backup Solutions for a Solar Factory

Given the state of the grid, a backup power strategy is not optional—it is a core component of the business plan. The choice of strategy carries long-term implications for operational costs and resilience.

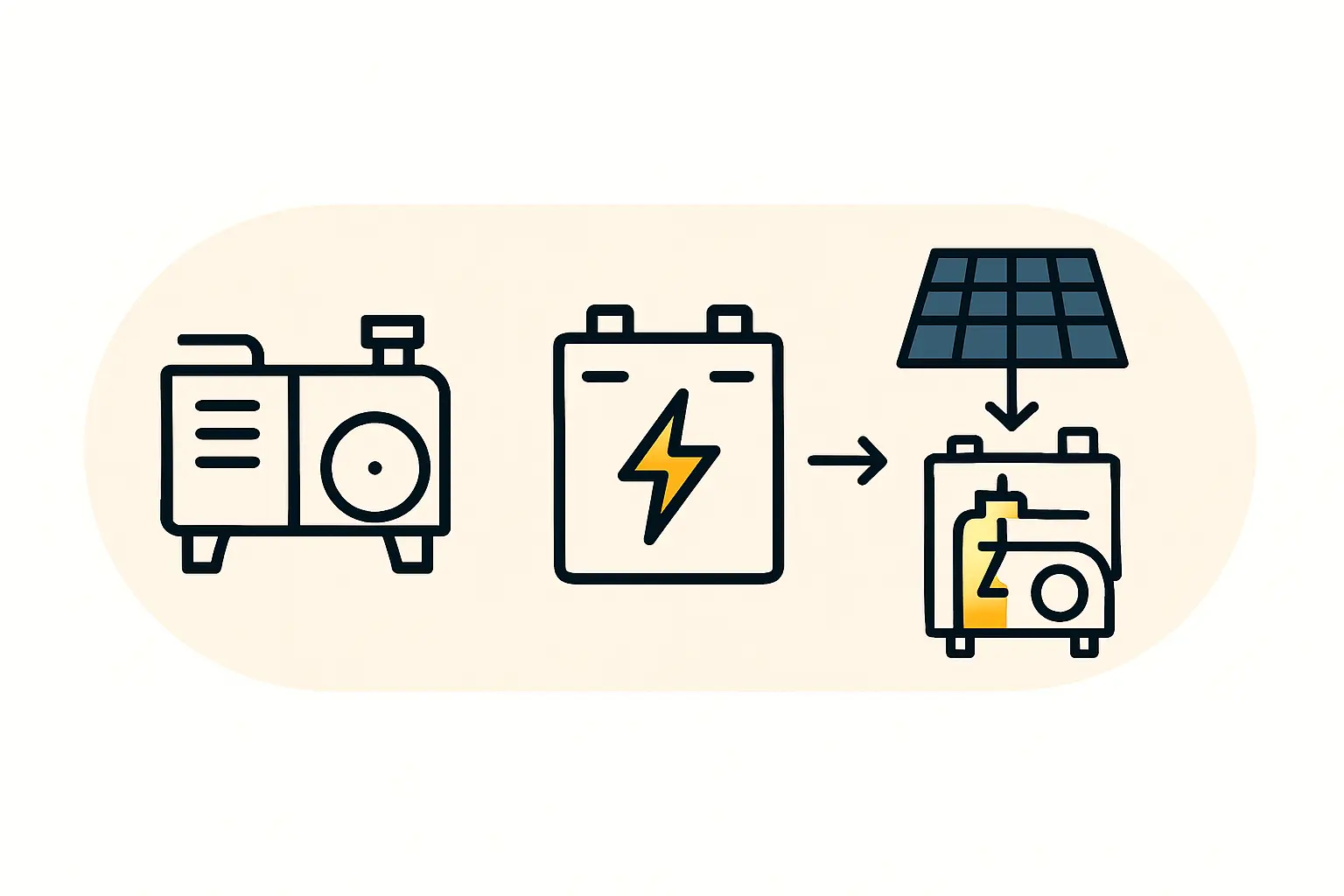

The Conventional Approach: Diesel Generators

For many industrial operations, a diesel generator is the default backup solution. While it can provide the necessary power, it comes with significant drawbacks:

- High Operating Costs: Diesel fuel is a major and often volatile expense. This cost is absorbed directly into the production cost of every solar module.

- Intensive Maintenance: Generators require regular servicing, oil changes, and repairs, adding to the operational burden.

- Environmental and Logistical Issues: Generators produce noise and emissions. Furthermore, ensuring a reliable supply of quality diesel can be a logistical challenge in itself.

Relying solely on diesel generators makes a business vulnerable to fuel price shocks and supply chain disruptions.

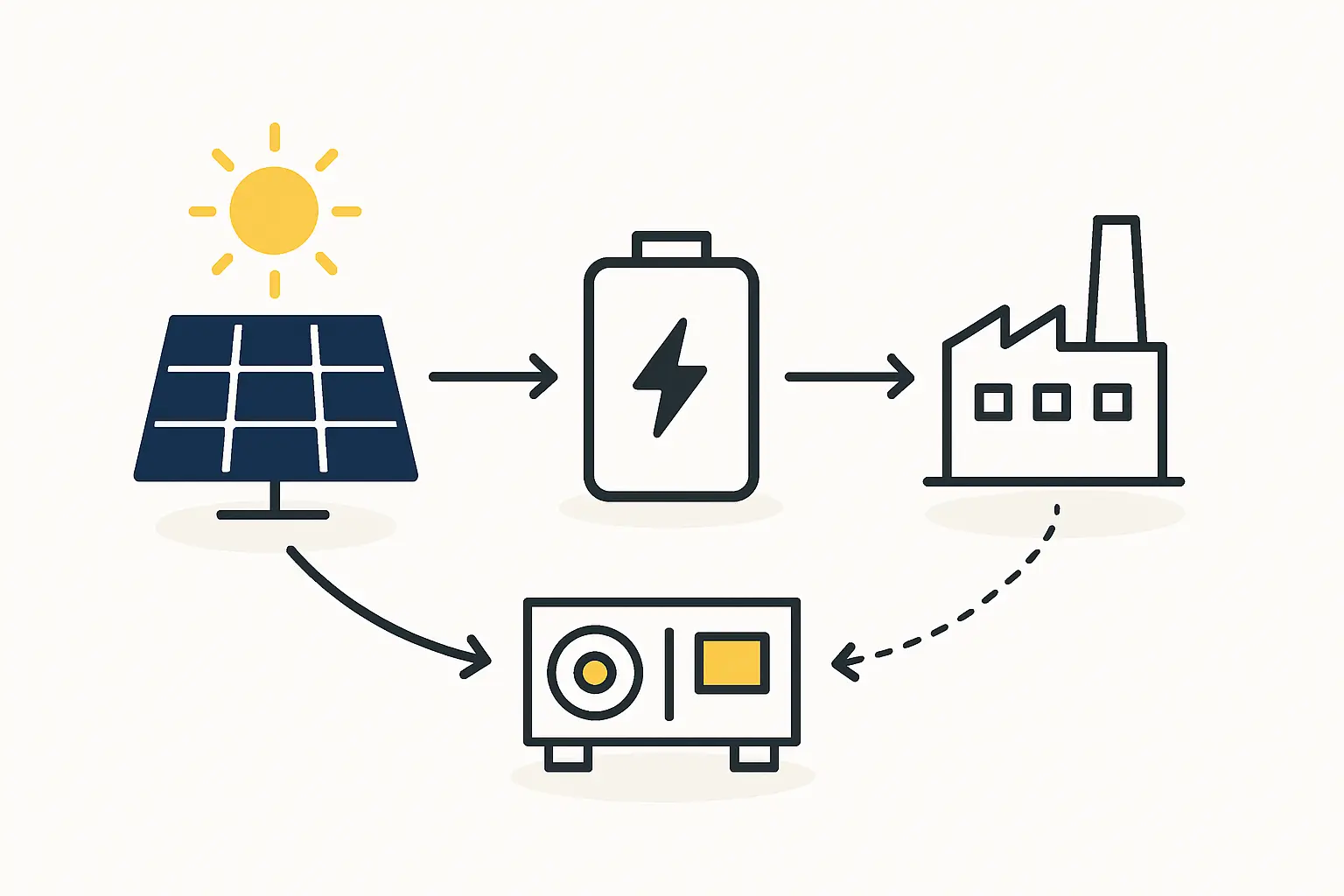

The Strategic Solution: A Hybrid Power System

A more robust and forward-thinking approach is a hybrid power system. This solution integrates multiple power sources to provide seamless, reliable electricity, leveraging the greatest strength of each component.

A typical hybrid system for a solar module factory includes:

- Grid Connection (Primary): The system draws from the national grid whenever it is stable and available, as this is usually the lowest-cost power source.

- On-Site Solar PV Array (Secondary): A dedicated solar installation, often on the factory roof or adjacent land, generates clean electricity during the day. This power can run the factory directly and charge the battery system.

- Battery Energy Storage System (BESS): As the heart of the solution, the BESS is charged by the solar array or the grid. If the grid fails, the BESS takes over instantly, providing uninterrupted power to the production line without any downtime or fluctuation.

- Diesel Generator (Tertiary/Backup): The generator’s role is reduced to a final layer of security. It only activates if the grid is down for an extended period and the BESS is depleted due to a lack of sun.

This integrated system ensures the factory has power under virtually any circumstance, drawing from the most economical source available at any given moment.

The Business Case for a Hybrid Power Solution

Investing in a hybrid system goes beyond just keeping the lights on. It is a strategic decision that builds a more resilient and profitable business from the ground up. While the initial solar panel manufacturing plant cost will be higher, the long-term benefits are compelling.

Enhancing Operational Resilience

The primary benefit is achieving near-100% operational uptime. This eliminates material waste from interrupted production cycles, protects sensitive equipment, and ensures that production targets and delivery schedules are met consistently. This level of reliability is a key factor in building a strong market reputation.

Managing Long-Term Operating Costs

By prioritizing power from the on-site solar array and the grid, the system drastically reduces reliance on expensive diesel fuel. Over the factory’s lifespan, savings on fuel and generator maintenance deliver a significant return on the initial investment, lowering the overall manufacturing cost per module.

Building a Credible, Sustainable Brand

A solar module factory powered by its own clean energy makes a powerful statement. It demonstrates a genuine commitment to the technology it sells and serves as a living showroom for the products. This enhances brand credibility and can be a strong marketing tool, particularly when dealing with international clients and partners who value sustainability.

Planning Your Factory’s Energy Infrastructure

Integrating a reliable power solution requires careful planning from the project’s earliest stages. It should be considered a core part of the factory design, not an accessory. Any entrepreneur exploring how to start a solar panel manufacturing business must prioritize this aspect.

Key planning steps include:

- Conduct a Detailed Energy Audit: Before purchasing any equipment, calculate the precise power requirements of the entire production line. This includes the peak load (when all machines run simultaneously) and the average daily energy consumption.

- Properly Size the System: Based on the energy audit and local solar irradiation data, an engineering partner can correctly size the PV array, BESS, and backup generator to ensure sufficient autonomy (e.g., the ability to run for 24 to 48 hours without grid power).

- Seek Expert Integration: Designing and integrating a hybrid power system is a complex engineering task. Partnering with a provider of a turnkey solar manufacturing line is often the most effective approach, as their experts can design the power infrastructure in parallel with the production line. Based on experience from J.v.G. turnkey projects, integrating the power solution from day one prevents costly retrofits later.

Frequently Asked Questions

Q: What is the typical power consumption of a small-scale solar module factory?

A: A semi-automated factory with a capacity of 20–50 MW per year typically requires a continuous power supply of 150 to 250 kW, with peaks that can be higher. The exact figure depends heavily on the machinery chosen.

Q: How much more does a hybrid system cost compared to just a diesel generator?

A: The initial capital expenditure for a hybrid system with solar and battery storage is significantly higher than for a standalone generator. However, a total cost of ownership (TCO) analysis often shows the hybrid system becomes more economical over 5–7 years due to substantial savings on fuel and maintenance.

Q: Can the solar modules produced by the factory be used for its own power system?

A: Absolutely. Using the factory’s own A-grade modules for its rooftop or ground-mounted PV array is an excellent way to reduce costs and showcase product quality.

Q: How does grid instability affect sensitive equipment like a cell stringer?

A: A cell stringer relies on consistent power for its delicate soldering heads and robotic arms. A voltage drop can cause poor solder joints (a major quality issue), while a power surge can damage its control boards. An uninterruptible power supply, as provided by a BESS, is essential.

Q: Is this power issue unique to Cameroon?

A: No, this challenge is common across many emerging markets in Africa, the Middle East, and parts of Asia. An integrated hybrid power system is a proven model for ensuring industrial resilience in regions with developing grid infrastructure.

From Power Challenge to Competitive Advantage

For any entrepreneur planning to enter the solar manufacturing space in Cameroon, the instability of the national grid should not be a deterrent but a known variable to be managed. Addressing this challenge head-on with a well-designed hybrid power system is a foundational investment in the long-term success of the business.

By securing an independent and reliable power supply, an investor effectively de-risks the entire operation. This turns a critical local challenge into a source of competitive strength, creating a factory that is not only resilient and efficient but also a powerful symbol of the very energy independence it promises its customers. With careful planning, a stable energy supply becomes the foundation upon which a successful and profitable manufacturing operation is built.