Entrepreneurs planning to establish a solar module factory in Cameroon might naturally focus first on the machinery and the building itself. But experience from countless projects, including those guided by J.v.G. Technology, shows that a resilient supply chain for raw materials is the true backbone of a successful manufacturing operation.

A state-of-the-art production line is of little use if it sits idle while a shipment of solar glass or EVA film is held up at the port. This article lays out a strategic framework for developing a robust supply chain for these critical raw materials in Cameroon.

We will examine the core components, evaluate the trade-offs between local sourcing and importation, and outline a proactive approach to mitigating the risks that can disrupt production and profitability. Grasping these fundamentals is key to creating a comprehensive business plan and a functional bill of materials.

Table of Contents

The Core Components of a Solar Module

Before diving into sourcing strategies, it’s essential to understand the primary materials that make up a solar module. While solar cells are the active component, three other structural materials are fundamental to a module’s longevity and performance: solar glass, EVA encapsulant, and the backsheet.

Solar Glass

This isn’t standard window glass. Solar-grade glass is a highly engineered product—typically low-iron, tempered glass with high solar transmittance. This global market is valued at over USD 50 billion and is dominated by a few large-scale international players. Its defining characteristic is a low iron content, often below 0.02%, which ensures a maximum amount of light reaches the solar cells.

EVA (Ethylene Vinyl Acetate)

EVA is a specialized polymer film used to encapsulate the solar cells, bonding them to the glass and the backsheet. It acts as a shock absorber, protects the cells from moisture and dirt, and ensures the module’s long-term stability. As a thermoset polymer, EVA requires strict, climate-controlled storage to prevent premature curing, which can render it unusable.

Backsheet

The backsheet is the module’s rearmost layer, typically a multi-layered polymer laminate designed for mechanical protection and electrical insulation. It must be exceptionally durable to withstand decades of exposure to UV radiation, humidity, and temperature fluctuations.

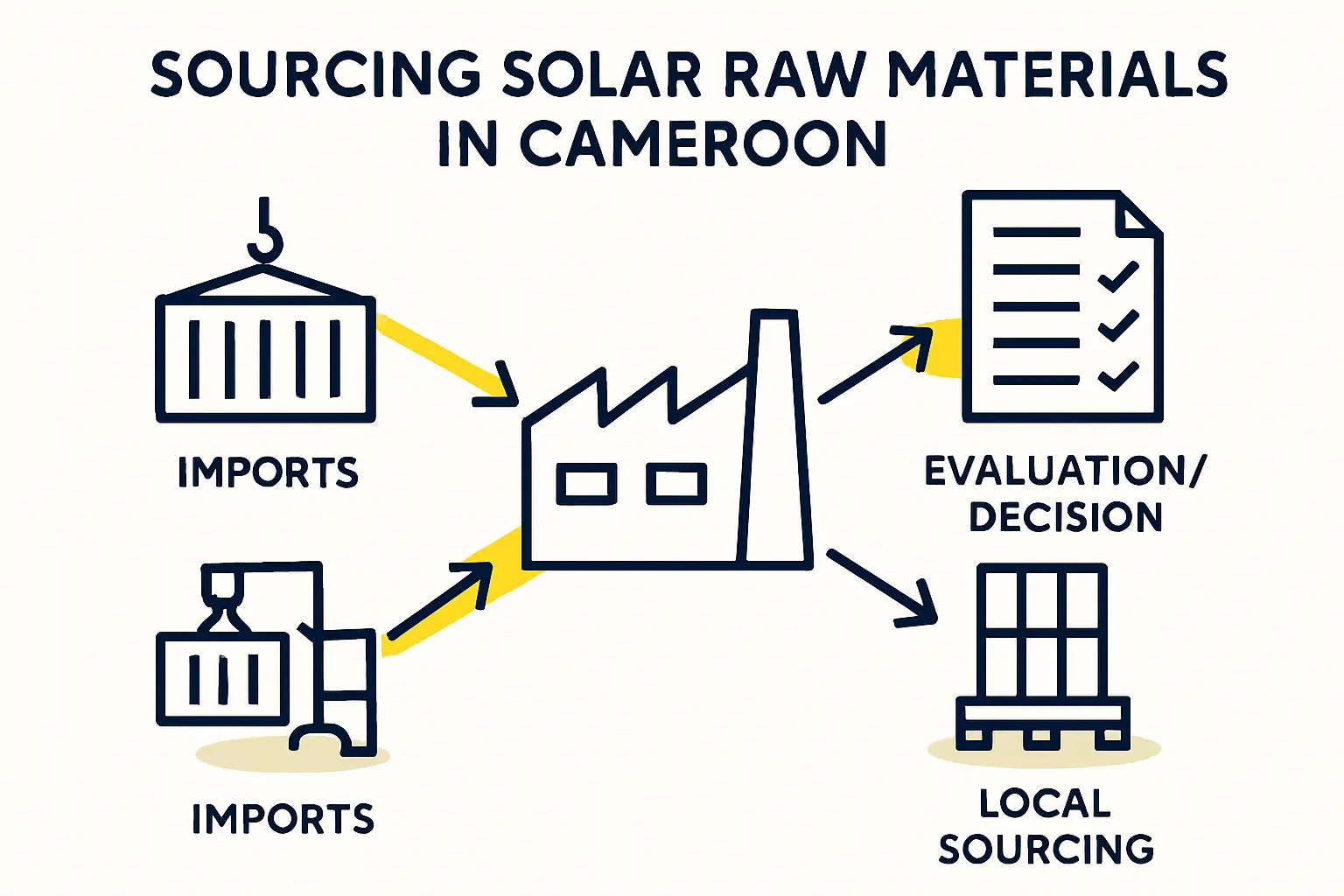

Local Sourcing vs. Importation: A Strategic Decision for Cameroon

For an entrepreneur in Cameroon, a central question is whether to source these materials locally or import them. Each path presents its own distinct advantages and considerable challenges, all of which must be carefully weighed.

The Case for Importation

For a newcomer to the solar manufacturing industry, importation is often the most pragmatic and reliable starting point for these three core materials. The primary reasons are:

- Quality and Certification: Established international suppliers provide materials that are already certified to key solar panel quality standards like IEC 61215 and IEC 61730. This is non-negotiable for producing bankable modules that can be used in commercial projects or sold internationally.

- Economies of Scale: The global solar industry is driven by immense scale. Large manufacturers in Asia and Europe produce high-quality materials at a cost per unit that is currently difficult for a new, smaller-scale local producer to match.

- Technical Specifications: The technical requirements for solar-grade materials are extremely precise. A reliable supply of low-iron glass or high-endurance backsheets from proven manufacturers removes a significant variable from the production process.

The Potential for Local Sourcing

While importing core components is the standard approach, exploring local sourcing for certain items is a crucial long-term strategy for cost control and supply chain resilience.

- Aluminum Frames: Aluminum frames are often the most viable candidate for local sourcing. If Cameroon has a domestic aluminum extrusion industry, sourcing frames locally can dramatically reduce shipping costs and import duties.

- Junction Boxes & Cables: Assembly of these components could be localized, provided the core electronic components are sourced from certified suppliers.

- Glass (Long-Term View): While Cameroon may not currently have a producer of solar-grade, low-iron glass, it is worth investigating the capabilities of existing glass manufacturers. Upgrading a facility to produce solar glass is a significant investment but could offer a major long-term strategic advantage for the country. This, however, is a multi-year development project, not a short-term solution for a new factory.

- Polymers (EVA/Backsheet): The production of these specialized polymers requires a sophisticated petrochemical industry, making local sourcing highly unlikely in the short to medium term.

For most businesses starting a turnkey solar module manufacturing line, a hybrid approach is the most effective. This involves importing the technically sensitive, certified materials (cells, glass, EVA, backsheet) while aggressively pursuing local suppliers for bulkier components like aluminum frames and packaging materials.

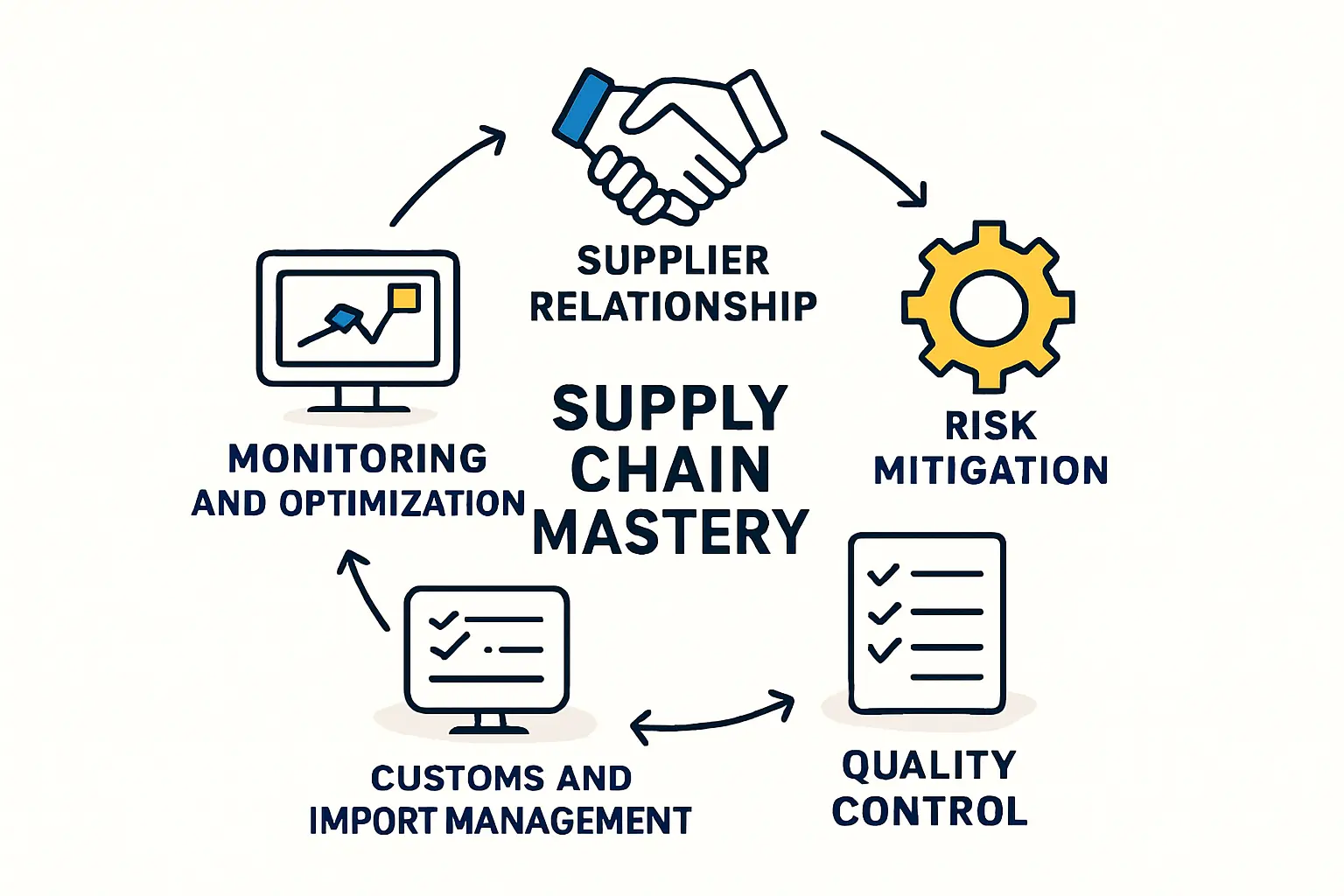

Mitigating Supply Chain Risks: A Proactive Framework

Any supply chain strategy is incomplete without a robust risk mitigation plan. Recent global disruptions have shown that even the most well-planned logistics can face unexpected challenges.

Supplier Diversification

Relying on a single supplier, even a large and reputable one, creates a single point of failure. A prudent strategy involves qualifying at least two or three suppliers from different companies and, if possible, different geographic regions. While sourcing from multiple suppliers can increase initial per-unit costs by 5-10%, this is a small price to pay for the insurance it provides against a complete production shutdown.

Quality Assurance and Vetting

Before signing any supply contract, a thorough vetting process is essential. This includes:

- Requesting and verifying certifications (e.g., IEC, TÜV, ISO).

- Auditing the supplier’s factory to assess their quality control processes.

- Ordering sample materials to test in small-batch production runs.

Logistics, Warehousing, and Customs

The journey from a supplier’s factory to the production line in Cameroon is fraught with potential bottlenecks.

- Port Congestion: For instance, a 2022 report highlighted that the Douala port can experience average container dwell times of 22 days—significantly higher than the global average of 7. This reality must be factored into inventory planning.

- Inland Transportation: The condition of roads and infrastructure for transporting fragile materials like large panes of glass requires careful assessment.

- Warehousing: Proper storage is critical. EVA and backsheets, for example, require climate-controlled environments to prevent degradation. Planning for adequate, secure, and climate-controlled warehousing is not an afterthought but a core operational requirement.

- Customs Navigation: Engaging an experienced and reliable local customs broker is indispensable. They can help navigate the tariff codes, documentation requirements, and bureaucratic procedures that can otherwise cause lengthy and costly delays.

Frequently Asked Questions (FAQ)

Q: Which raw materials are the most critical to get right from the start?

A: The “holy trinity” of materials are the solar cells, the glass, and the EVA encapsulant. A failure in any of these three components will almost certainly cause the entire solar module to fail within its 25-year expected lifespan. Quality here is paramount.

Q: How much buffer stock of raw materials should a new factory keep?

A: Given the potential for shipping delays and port congestion in West Africa, a new factory should aim to hold at least three to six months’ worth of key raw material inventory. This provides a crucial buffer to maintain continuous production through shipment delays.

Q: Can standard window glass be used for solar panels to save costs?

A: No. Standard “float” glass has a high iron content, which gives it a slight green tint when viewed from the edge. This iron absorbs a portion of the incoming sunlight, significantly reducing the amount of energy that reaches the solar cells and thereby lowering the module’s overall efficiency and power output.

Q: How can a new entrepreneur vet international suppliers from Cameroon?

A: This is a significant challenge that often requires third-party support. Organizations like J.v.G. Technology utilize their decades of experience and global network to help clients identify, vet, and qualify reliable suppliers as part of a turnkey factory setup, removing the guesswork and reducing risk for the new business owner.

The Path Forward

Establishing a solar module manufacturing facility in Cameroon is a venture with immense potential. Success, however, depends less on the speed of the machines and more on the steady, reliable flow of high-quality raw materials.

By adopting a pragmatic hybrid sourcing model, diversifying suppliers, and meticulously planning for regional logistics, an entrepreneur can build a resilient operation capable of weathering supply chain uncertainties.

The next step is to translate this strategic understanding into a detailed operational and financial plan. A well-defined supply chain strategy is essential for calculating working capital requirements and forecasting long-term profitability.