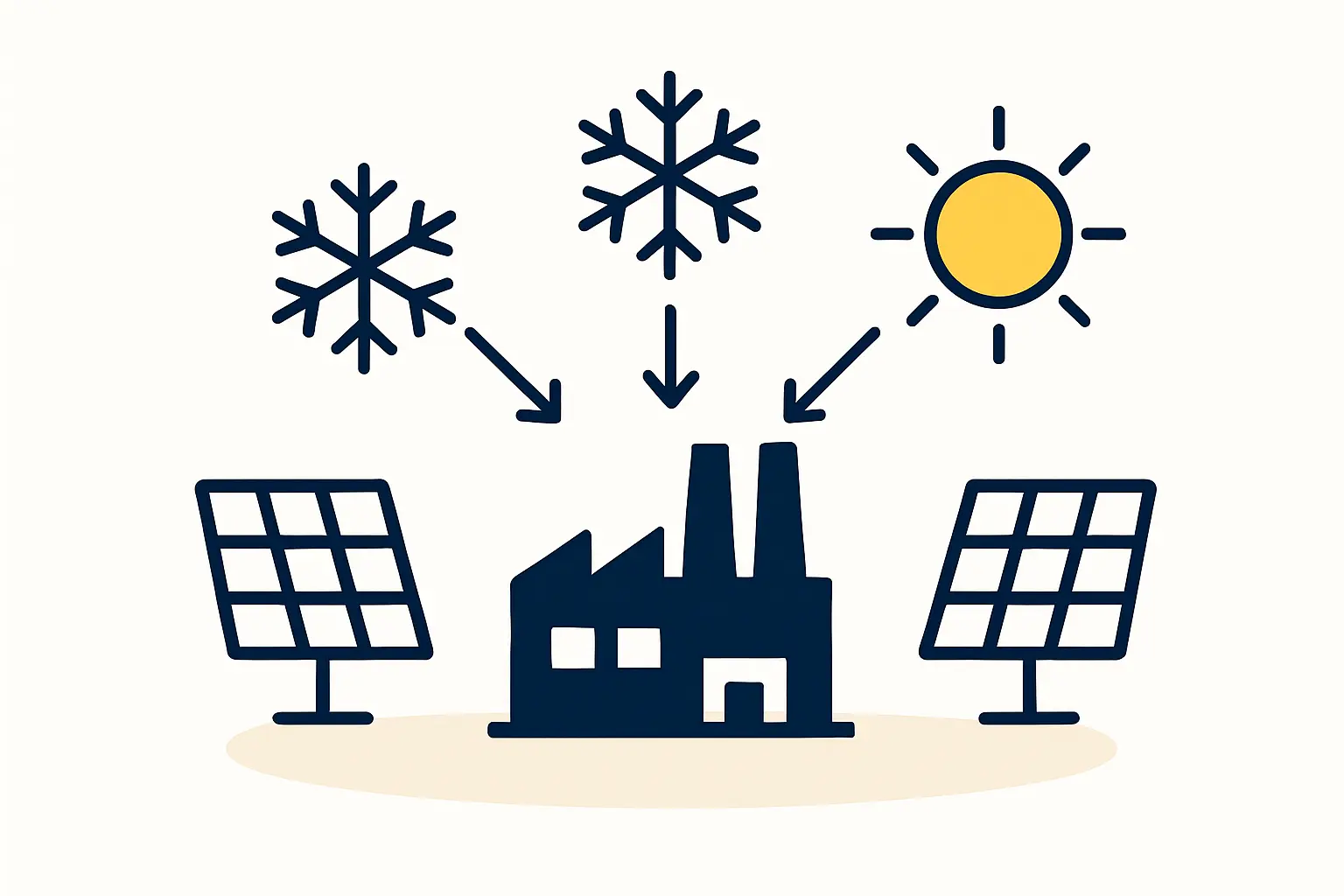

When planning a solar module factory, entrepreneurs often focus on machinery, materials, and market demand. One of the most critical—and often underestimated—factors, however, is the local climate. A manufacturing facility in Dubai faces entirely different operational challenges than one in Germany. In regions with extreme cold like Canada, these challenges become even more specialized, as sub-zero temperatures pose unique engineering and process-related hurdles.

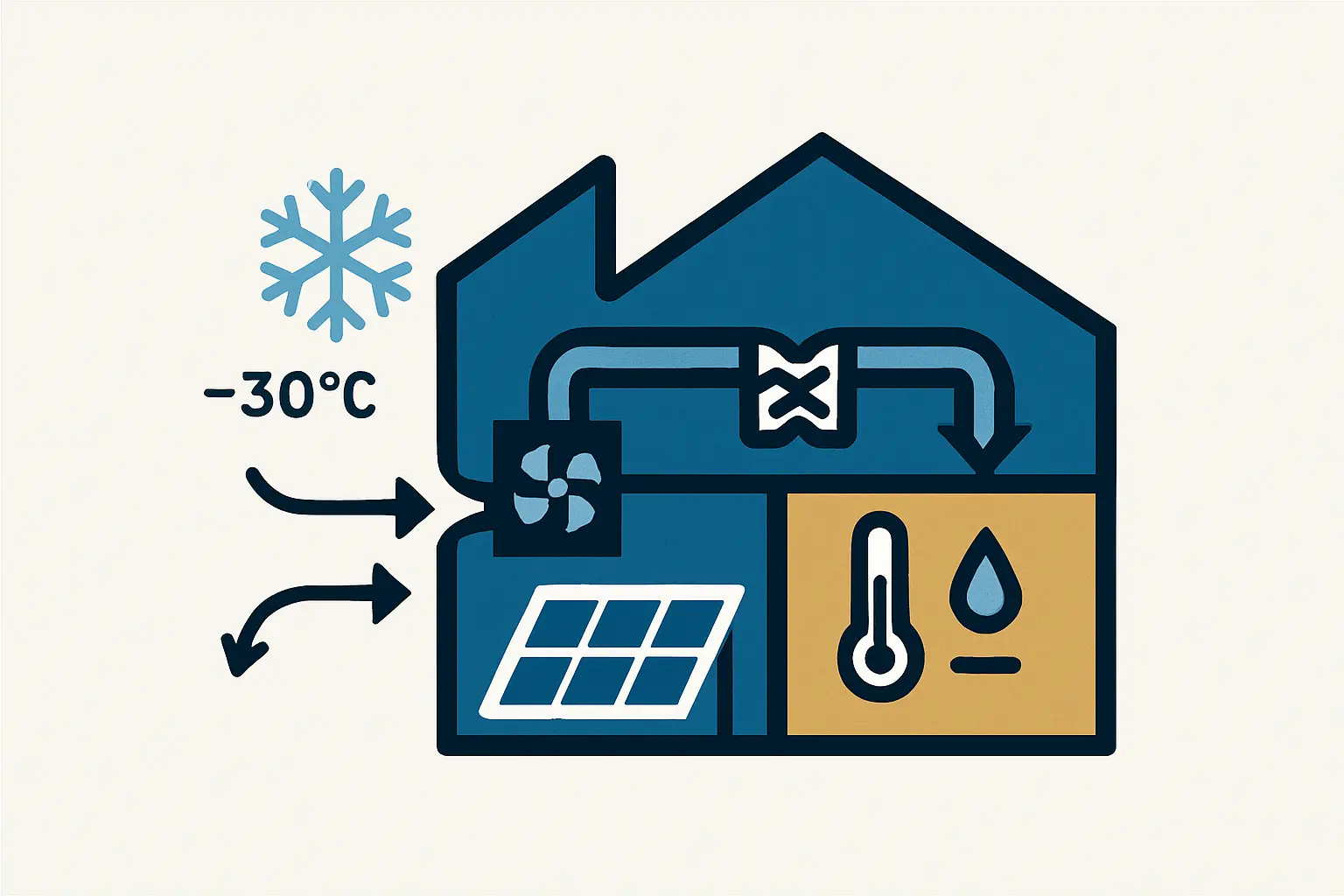

Imagine a production facility where the outside temperature can plummet to -40°C, while inside, a sensitive chemical process requires a stable environment of +25°C with controlled humidity. This scenario isn’t hypothetical; it’s a reality for solar manufacturers in northern latitudes. Drawing on experience from J.v.G. turnkey projects, this article explores the essential operational considerations for running a solar module factory in a cold climate, using a Canadian project as a practical example.

Table of Contents

The Impact of Extreme Cold on Factory Infrastructure

The first line of defense against a harsh climate is the building itself. In regions like Canada, standard industrial construction is often insufficient to meet the demands of a high-tech manufacturing process.

Structural Integrity and Snow Load

In many parts of Canada, annual snowfall can accumulate to significant depths. For one J.v.G. client, the factory had to be designed to withstand a potential snow load of up to four meters on its roof. This requires a substantial investment in structural engineering, with reinforced beams and a roof design that can bear immense weight over long periods. Failure to account for this risk can lead to catastrophic structural failure, halting production and endangering staff. A thorough understanding of local building codes and meteorological data is a non-negotiable first step.

Insulation and Energy Efficiency

Maintaining a stable indoor temperature when it is -40°C outside creates an enormous thermal gradient. The building envelope—walls, roof, windows, and doors—must be exceptionally well-insulated to prevent heat loss. This not only ensures a stable production environment but also directly impacts operational costs. Inadequate insulation means heating systems must run constantly, leading to steep energy bills that can erode profitability.

Climate Control: The Critical Role of HVAC Systems

Nowhere is the challenge of a cold climate more apparent than in the lamination area. The solar module lamination process, where the layers of the module are bonded together, is highly sensitive to temperature and humidity.

For optimal cross-linking of the encapsulant material (typically EVA or POE), ambient conditions must be strictly maintained within a narrow window:

- Temperature: 22–25°C.

- Relative Humidity: Below 60%.

Achieving these conditions in a Canadian winter requires a sophisticated and powerful Heating, Ventilation, and Air Conditioning (HVAC) system. The system must not only heat a large volume of frigid air drawn from outside but also precisely manage its moisture content. While cold air is naturally dry, industrial processes and personnel can introduce humidity that must also be controlled.

The HVAC system must constantly balance these factors, making it one of the most critical and energy-intensive components of the factory. The initial capital expenditure (CAPEX) for such a system is considerably higher than for a factory in a temperate climate, and its ongoing energy consumption (OPEX) must be carefully factored into the business model.

Managing Materials in Sub-Zero Temperatures

The challenges of a cold climate extend beyond the building to the raw materials themselves. These are often transported and delivered in unheated trucks, arriving at the facility at ambient temperatures that can be far below freezing.

The Risk of Condensation

Introducing frozen materials directly into a warm, relatively humid production environment creates a significant risk of condensation. As the cold surfaces of glass, backsheets, or encapsulant foils meet warmer air, moisture will form on them. If this microscopic layer of water is not eliminated before lamination, it becomes trapped within the module. During lamination, this moisture turns to steam, creating bubbles, delamination, and long-term reliability issues that can lead to premature module failure.

Material Brittleness and Handling

Many polymers used in solar modules, such as EVA foil, can become brittle at very low temperatures. Handling them in this state increases the risk of cracking or other physical damage, leading to material waste and production delays.

The Solution: An Acclimatization Zone

To mitigate these risks, a dedicated acclimatization room or zone is essential. This is a designated area where incoming materials are stored for a set period to allow them to warm up slowly and controllably to the factory’s ambient temperature. This process ensures that no condensation forms on the material surfaces before they enter the production line. This critical step must be integrated into the factory’s material handling protocols and physical layout from day one.

Business Implications and Strategic Planning

Operating a solar module factory in a cold climate is entirely feasible but requires meticulous planning and a clear understanding of the associated costs. The key business takeaways are:

- Increased Initial Investment: Expect higher CAPEX for building construction (structural reinforcement, advanced insulation) and for a high-capacity, precision HVAC system.

- Higher Operational Costs: Energy consumption for heating and climate control will be a significant and recurring OPEX line item. This must be accurately forecasted in your financial model.

- Process Integration: The factory layout and workflow must incorporate cold-climate-specific processes, such as the material acclimatization zone, which impacts space and logistics.

- Expert Consultation: Engaging with engineers and consultants who have direct experience with these specific conditions is crucial to prevent costly mistakes in the design and planning stages.

By anticipating these issues, a business can develop a robust operational plan and a realistic financial model that accounts for the unique demands of its environment. Platforms like pvknowhow.com provide structured guidance to help entrepreneurs navigate these complex, region-specific challenges.

Frequently Asked Questions (FAQ)

Q: Why is humidity control so important for lamination?

A: Moisture trapped between the layers of a solar module during lamination can turn to steam under the process’s heat and pressure. This creates bubbles or voids, preventing the encapsulant from bonding correctly. Over time, this leads to delamination, moisture ingress, and ultimately, the failure of the solar module.

Q: How much more expensive is it to run a factory in a cold climate?

A: The exact cost increase depends on local energy prices, climate severity, and the efficiency of the building and HVAC system. However, energy costs for heating and climate control can be a substantial portion of the factory’s total operational expenditure and must be carefully calculated in the initial business plan.

Q: Can standard factory buildings be retrofitted for these conditions?

A: While retrofitting is possible, it is often more complex and less efficient than a purpose-built facility. Addressing key areas like roof strength for snow load, wall insulation, and integrating a large-scale HVAC system can be challenging and costly in an existing structure not designed for such extremes.

Q: Does the external temperature affect the solar modules themselves during production?

A: The external temperature doesn’t directly affect the modules during the indoor assembly process, but its indirect effects are critical. Managing raw materials that arrive at sub-zero temperatures is paramount for preventing defects like condensation, which can compromise the final product’s quality and long-term reliability.