A common concern for entrepreneurs entering the solar manufacturing sector is the availability of a skilled local workforce. The perception is often that a new factory requires a large team of highly specialized photovoltaic experts—a pool of talent that can be difficult to find, particularly in emerging markets. The reality, however, is that a successful solar module factory can be run by a team built primarily from local talent, provided the right recruitment and training models are in place.

The global solar PV sector is a significant employer, growing to 4.9 million jobs in 2022, according to the International Renewable Energy Agency (IRENA). A substantial portion of these roles are in manufacturing. This boom presents a major economic opportunity, but it also underscores the critical need for effective workforce development. This article outlines strategies for recruiting and training the team needed for a new solar module factory, transforming a potential barrier into a strategic advantage. It explains typical labor requirements and offers proven models for building a capable, self-sufficient team.

Table of Contents

The Two Tiers of a Solar Factory Workforce

J.v.G. Technology’s experience with turnkey projects shows that a factory’s workforce generally divides into two distinct groups. Understanding this 80/20 split is fundamental to designing an effective training program.

The Core Workforce: Production Operators (Approx. 80% of Staff)

The majority of employees in a semi-automated solar module factory are production operators.

Their responsibilities include:

- Loading and unloading materials like glass, solar cells, and backsheets.

- Operating specific machines along the solar panel production line, such as the stringer, layup station, and laminator.

- Performing visual inspections at various stages of production.

- Handling finished modules for framing and testing.

Crucially, these roles do not require prior experience in the solar industry. Ideal candidates are individuals with good manual dexterity, attention to detail, and an aptitude for process-oriented work. Based on internal data from numerous factory setups, these operators can achieve a high level of proficiency within four to six weeks of on-site training.

The Specialist Team: Engineers and Technicians (Approx. 20% of Staff)

This smaller, more specialized group forms the technical backbone of the factory. Their roles require a formal technical education, typically in electrical, mechanical, or industrial engineering.

This team is responsible for:

- Machine Maintenance: Performing preventative maintenance and troubleshooting equipment issues.

- Process Engineering: Optimizing the production flow and ensuring all parameters meet specifications.

- Quality Control: Implementing and overseeing the standards for quality control in solar module manufacturing, including material inspection and final product testing.

While these individuals need a solid technical foundation, they do not necessarily need prior PV-specific experience. Their existing engineering knowledge provides the ideal foundation on which to build solar-specific skills.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

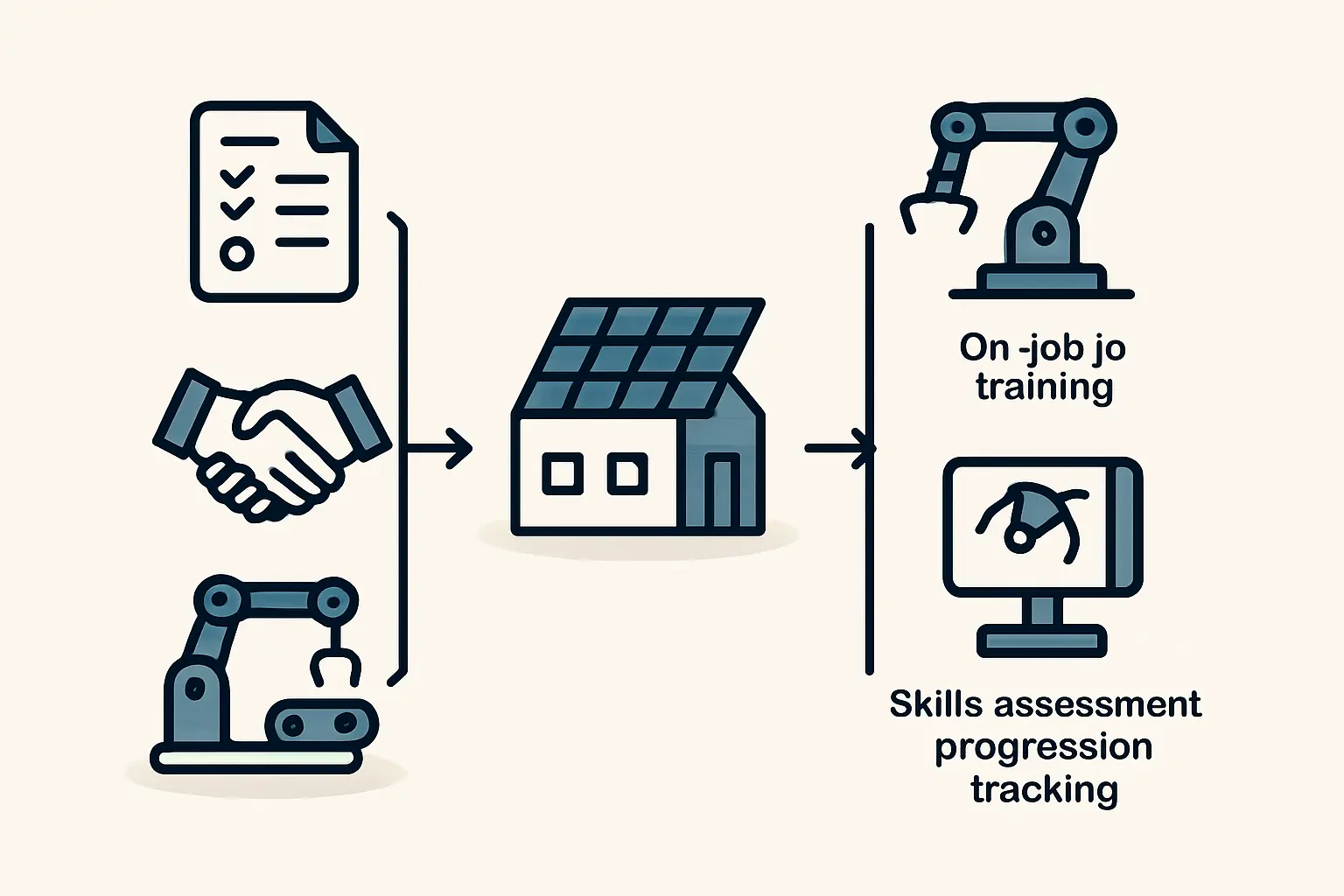

Strategic Models for Workforce Development

Reports from institutions like the World Bank Group have noted a skills mismatch in Sub-Saharan Africa, where traditional vocational training often fails to meet the specific needs of the renewable energy industry. Overcoming this challenge requires proactive training models.

Model 1: The In-House, On-the-Job Training Program

This is the most effective way to train the core workforce of production operators. The training is practical, hands-on, and conducted directly on the production floor as the machinery is commissioned.

Equipment supplier’s engineers typically lead this process, remaining on-site for several weeks. They work directly with newly hired operators, demonstrating each step, explaining safety protocols, and supervising initial production runs. This direct knowledge transfer is the fastest way to build competence and confidence.

Model 2: The “Train the Trainer” Approach for Specialists

For the engineering and maintenance team, a more intensive approach is required. The “train the trainer” model has proven highly effective. In this model, a select group of the factory’s key local engineers and technicians travels to the equipment manufacturer’s facility in Europe or Asia for several weeks of in-depth training.

During this period, they learn the theoretical principles behind the technology, advanced machine operation, and critical maintenance procedures. This dedicated learning environment ensures they grasp the core concepts without the pressures of a live production line. Upon their return, these specialists become the in-house trainers, responsible for the ongoing development of the entire technical team.

Model 3: Partnering with Local Educational Institutions

For long-term sustainability, partnering with a local university or technical college is a powerful strategy. This approach creates a continuous pipeline of talent for future expansion and staff turnover.

As a successful case study by GIZ (German Agency for International Cooperation) in Nigeria demonstrates, collaboration between industry and academia can bridge the skills gap.

A solar manufacturer can work with an institution to:

- Co-develop Curricula: Help shape courses to include relevant topics in PV technology and manufacturing processes.

- Offer Internships: Provide students with practical, real-world experience in the factory.

- Sponsor Final-Year Projects: Engage students with real challenges from the production line.

This not only ensures a supply of qualified candidates but also elevates the technical capacity of the local community and positions the company as a key contributor to regional development.

A Phased Approach to Building Your Team

A structured timeline ensures that the right people are trained at the right time.

- Phase 1 (Pre-Commissioning): The core engineering and quality control team is hired first, as this is the group that typically travels for the “train the trainer” program.

- Phase 2 (Commissioning): Production operators are recruited and onboarded. Their training coincides with the installation and testing of the production line, led by the equipment supplier and the newly trained local specialists.

- Phase 3 (Post-Launch): The focus shifts to continuous professional development. This includes cross-training operators on different machines and providing advanced training for the engineering team.

Frequently Asked Questions (FAQ)

Q: Do we need to hire expensive expatriate managers for the long term?

A: It’s common to have an experienced expatriate production manager on-site for the first 6-12 months to oversee the ramp-up and establish best practices. However, a primary goal of the “train the trainer” model is to develop a local manager who can assume full responsibility, making the expatriate role a temporary bridge, not a permanent necessity.

Q: What is the typical staff count for a small-scale factory?

A: A semi-automated 20–50 MW factory typically requires 25 to 30 employees per shift to operate efficiently. This number includes operators, technicians, quality control personnel, and supervisors.

Q: How long does it take for a new team to become fully productive?

A: Operators typically achieve initial proficiency within four to six weeks of hands-on training. The entire production line usually reaches its target efficiency and output levels within three to six months as processes are refined and the team gains experience working together.

Q: Can we recruit from other manufacturing industries?

A: Yes, this is an excellent source of talent, especially for operator roles. Individuals with experience in electronics assembly, textiles, or other industries that require attention to detail and process discipline often adapt very quickly to solar module manufacturing.

Conclusion: A Developable Asset

Building a skilled workforce for a solar module factory in an emerging market is not about finding perfectly qualified individuals from day one, but about establishing a system to develop them. By understanding the workforce’s different skill requirements, implementing structured training, and partnering with local institutions, an entrepreneur can build a capable, efficient, and self-sufficient team from local talent. This approach reduces long-term operational costs, fosters local economic growth, and turns the workforce into one of the factory’s most valuable assets.