An entrepreneur entering Colombia’s growing solar market, perhaps planning a new black frame solar panel enterprise, often focuses on the big picture: factory setup, machinery, and market demand. Before long, however, a crucial question emerges that can define the entire business case: “Where will the raw materials come from?”

The decision between sourcing components locally and relying on international imports is one of the most strategic choices a new solar panel manufacturer will make. This analysis examines the feasibility of both approaches within the Colombian context, weighing which components can realistically be sourced locally against those best imported. The goal is to provide a framework for building a resilient and cost-effective supply chain.

Table of Contents

The Strategic Importance of Your Supply Chain

The choice of suppliers is more than a line item in a budget—it directly impacts production timelines, final product quality, and logistical complexity. A well-planned supply chain minimizes risk, while a poorly considered one can lead to costly delays and quality issues. These sourcing decisions are fundamental to calculating the total cost of a solar panel factory and must be addressed in the earliest stages of business planning.

Driven by government incentives like Law 1715 (2014) and Law 2099 (2021), Colombia has fostered a favorable environment for renewable energy projects. These regulations offer tangible benefits, including income tax deductions and exemptions from VAT and import tariffs for equipment and materials. This framework makes both local production and strategic importation financially viable.

Assessing Local Sourcing Potential in Colombia

For a new manufacturing venture, leveraging a country’s existing industrial capacity can provide a significant competitive advantage. Colombia has established industries that offer promising synergies for solar component manufacturing.

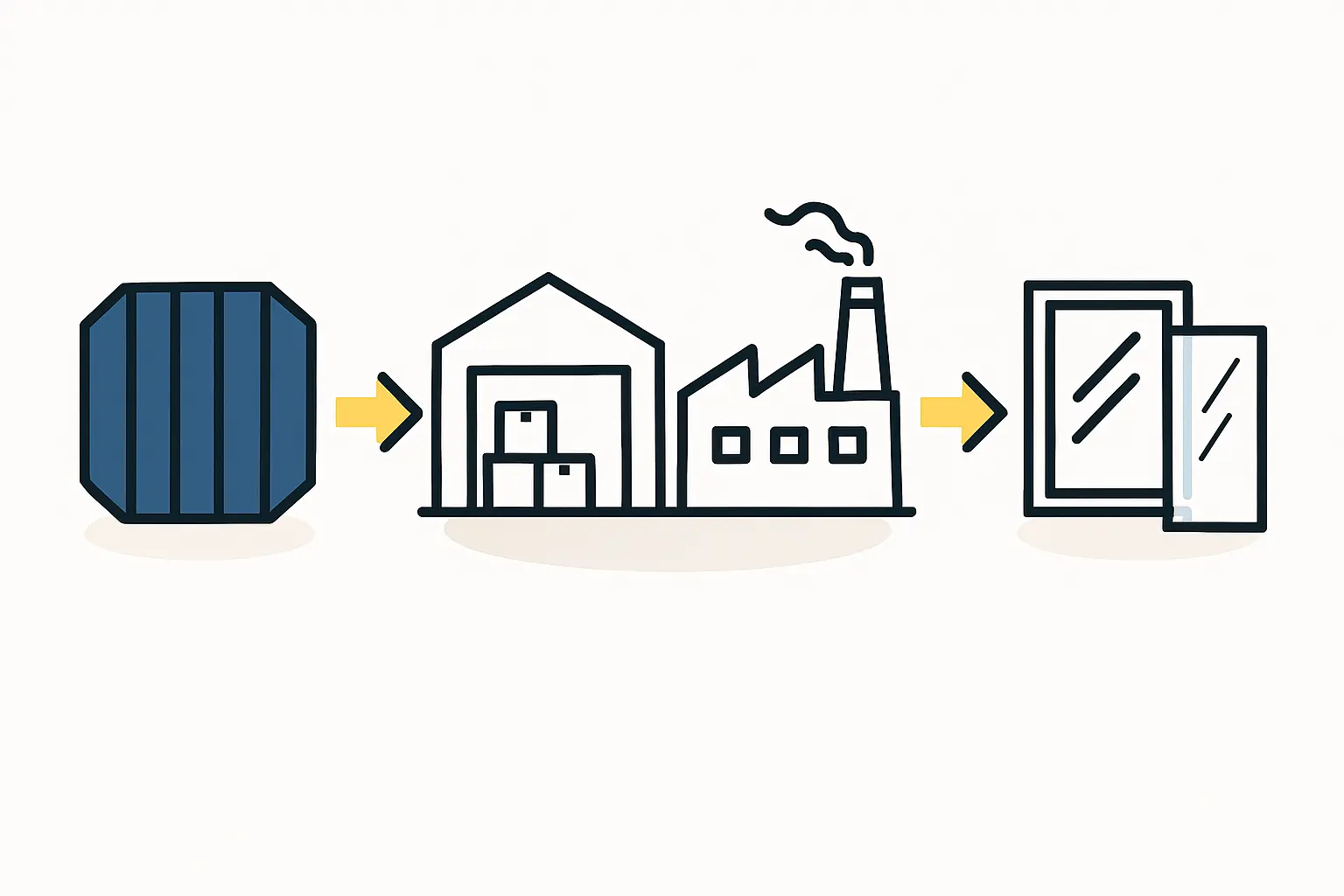

Aluminum Frames: The Strongest Case for Localization

The aluminum frame is a critical structural component that protects the laminate and provides the means for mounting the solar panel. It is also one of the module’s bulkiest and heaviest parts.

Colombia has a well-developed aluminum extrusion industry, with established companies capable of producing complex profiles. This makes aluminum frames a clear opportunity for localization.

Benefits: Sourcing frames locally can drastically reduce shipping costs and exposure to international freight volatility. It also allows for shorter lead times and more agile inventory management.

Challenges: The primary challenge is technical. Solar panel frames require high-precision manufacturing and specific anodization thicknesses to withstand decades of outdoor exposure. Any local supplier must be able to meet these stringent quality standards consistently. Vetting and co-developing the product with a local partner is therefore essential.

Solar Glass: A Feasible but Capital-Intensive Opportunity

The front glass of a solar panel is a highly specialized product. It must be low-iron for maximum light transmission, fully tempered for strength, and often features an anti-reflective coating.

While Colombia has major glass manufacturers, producing solar-grade glass requires a dedicated production line—a significant capital investment. An existing manufacturer would need a strong business case to justify modifying or building a facility for this purpose. For a new solar factory, this is more of a long-term possibility than an immediate solution.

Junction Boxes and Packaging: Exploring the Ancillaries

Junction Boxes: These enclosures protect the electrical connections on the back of the panel. While Colombia’s plastics and electronics industries could potentially produce them, the technical requirements are demanding. Junction boxes require high IP ratings (e.g., IP67 or IP68) for water and dust protection. They must also be made from UV-stable materials certified for high-voltage DC applications. The risk of sourcing a non-compliant component is substantial.

Packaging: Materials like cardboard boxes, corner protectors, and strapping are excellent candidates for local sourcing. Because they are not technically complex, procuring them locally can offer significant cost savings and logistical simplicity.

The Reality of Imports: Essential High-Tech Components

Despite the potential for local sourcing, certain core components of a solar panel emerge from a highly specialized, capital-intensive global supply chain. For any new manufacturer in Colombia, importing these is a practical necessity.

Solar Cells and Silicon Wafers: The Heart of the Module

The solar cell is the semiconductor device that converts sunlight into electricity. Its manufacturing involves complex processes, from growing silicon ingots to wafering, doping, and coating. This industry is dominated by a handful of major international players and requires billions of dollars in investment to establish.

For this reason, solar cells will remain an imported component for the foreseeable future. A key part of the solar panel manufacturing process involves carefully assembling these imported cells into strings.

Encapsulants (EVA) and Backsheets: Specialized Polymers

Ethylene Vinyl Acetate (EVA) is the adhesive film used to laminate the layers of the panel, while the backsheet provides electrical insulation and mechanical protection. Both are specialized polymer products manufactured in large chemical facilities. The market is concentrated among a few global suppliers, making importation the only practical option.

A Practical Framework: Balancing Cost, Quality, and Logistics

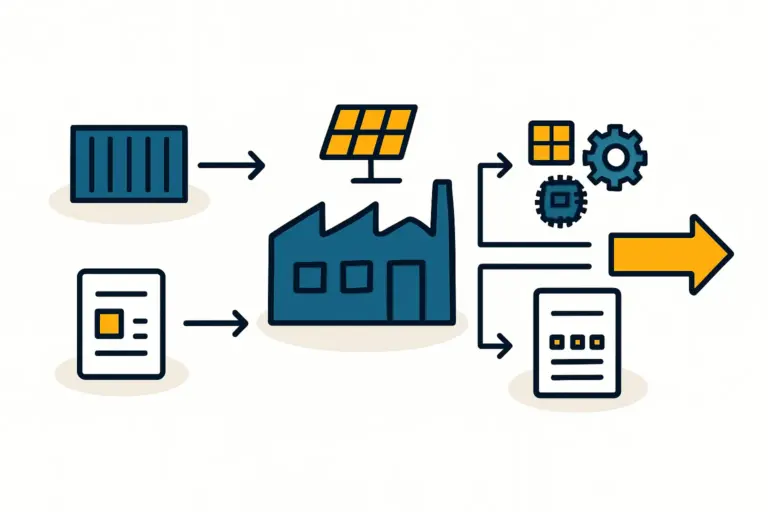

The most effective strategy for a new Colombian solar panel manufacturer is a hybrid model that balances the benefits of local sourcing with the realities of the global market.

The Hybrid Model: A Recommended Starting Point

A pragmatic approach involves focusing localization efforts where they provide the most immediate impact:

- Import Core Components: Source high-tech, critical items like solar cells, EVA, and backsheets from reputable international suppliers.

- Localize Bulky Components: Actively pursue partnerships with local companies for aluminum frames and all packaging materials.

This strategy mitigates technical risk while capturing significant logistical cost savings. As the operation scales, further localization of components like junction boxes or even glass can be explored.

Navigating Import Logistics and Quality Control

When importing materials, logistical efficiency is key. Colombia’s major ports in Cartagena and Buenaventura are well-equipped to handle international freight, but inland transportation costs and timelines must be factored into the overall business plan.

Crucially, a robust system for solar panel quality control must begin with incoming materials. Experience in turnkey projects shows that establishing strict inspection protocols for all imported goods is non-negotiable. Identifying a defect upon arrival is far more cost-effective than discovering it after a component has been integrated into a finished product.

Leveraging Colombia’s Incentives

The government’s supportive policies are designed to ease the financial burden of establishing a new energy enterprise. The VAT and tariff exemptions under Law 2099 apply directly to imported raw materials and machinery for a turnkey solar panel production line, strengthening the business case for the hybrid import-local model.

Frequently Asked Questions (FAQ)

Q: Which component offers the best starting point for local sourcing?

A: Aluminum frames are the most logical place to start. They are bulky, expensive to ship, and Colombia has an existing industrial base capable of producing them, provided the technical specifications can be met.

Q: Do I need a technical background to manage this supply chain?

A: While a technical background is helpful, it isn’t a prerequisite. What’s essential is a structured approach to supplier vetting and quality control, often guided by an experienced technical partner. The goal is to establish clear specifications and verification processes, not to be an expert in every material.

Q: How do import tariffs affect the business plan?

A: Under current legislation (Law 2099), equipment, materials, and machinery for renewable energy production are generally exempt from VAT and customs tariffs. This significantly reduces the cost of imported components and is a critical factor in the financial viability of a new manufacturing plant.

Q: Can a turnkey solar panel production line be adapted for locally sourced materials?

A: Yes, a modern production line is designed for flexibility. However, the specifications of all raw materials—whether imported or locally sourced—must be clearly defined during the factory planning phase. This ensures that machinery, such as framing stations, is calibrated correctly for the specific components being used.

Conclusion: Building a Resilient Colombian Solar Supply Chain

Entering the solar manufacturing sector in Colombia is a promising venture, backed by strong government support and growing market demand. Success, however, depends on building a smart and resilient supply chain.

A hybrid strategy that leverages Colombia’s industrial strengths for bulky components while relying on established global suppliers for high-tech materials offers the most balanced, lowest-risk path forward. By carefully planning this foundational aspect of your business, you can build a competitive and sustainable operation poised to power Colombia’s clean energy future.