To an entrepreneur exploring the solar industry, a standard solar module might seem like a one-size-fits-all solution.

But in a market like the Union of the Comoros, deploying a generic product can lead to premature failure and significant financial loss. The region’s unique challenges, from energy infrastructure deficits to severe weather, demand a more strategic approach to solar module design and manufacturing.

This article outlines the critical environmental and application-specific factors for producing solar modules for the Comorian market. Understanding these requirements is the first step toward building a sustainable and profitable solar enterprise in a region with immense untapped potential.

Table of Contents

Understanding the Comorian Energy and Environmental Landscape

The Comoros, an archipelago in the Indian Ocean, faces a distinct set of energy and climate challenges that directly influence the viability of solar technology. Successful solar projects must be designed with these local realities in mind.

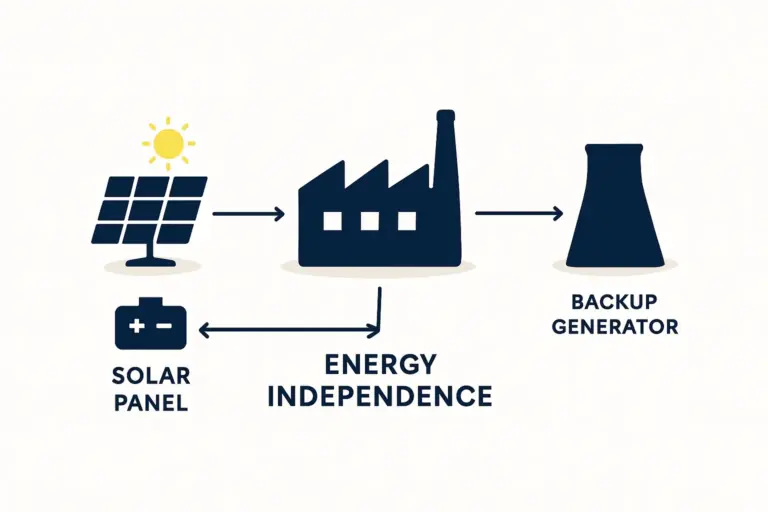

The nation’s installed electricity capacity is approximately 11 MW, mostly from diesel generators. Serving less than 70% of the population, this network is susceptible to frequent outages and the high cost of imported fuel, creating a substantial opportunity for decentralized solar solutions.

At the same time, the climate presents significant technical hurdles:

- Exceptional Solar Irradiation: With 5-6 kWh/m²/day, the solar resource is abundant, making PV technology an ideal energy source.

- Tropical Maritime Climate: The islands experience constant high humidity and salt-laden air from the ocean. This combination is highly corrosive to standard electronic and mechanical components.

- High Cyclone Risk: The region is prone to severe tropical cyclones. In 2019, Cyclone Kenneth caused widespread destruction, demonstrating the need for infrastructure capable of withstanding extreme wind loads.

Consequently, a solar module that performs reliably in a dry, continental climate might not survive more than a few years in the Comoros without specialized design features.

Key Technical Specifications for Cyclone Resilience

While standard solar modules are typically tested to withstand a static mechanical load of 2400 Pascals (Pa)—equivalent to wind speeds of around 130 km/h—this is simply insufficient for a cyclone-prone region like the Comoros. Modules destined for the islands must be engineered to endure far higher stresses.

Key enhancements include:

- Thicker Tempered Glass: Increasing the front glass thickness from the standard 3.2 mm to 4.0 mm significantly enhances a module’s resistance to physical impact from debris and the pressure from high winds.

- Reinforced Anodized Aluminum Frames: A robust frame is critical. Using a depth of 40 mm or more—compared to the common 30-35 mm—provides superior structural integrity, while anodization adds a crucial layer of protection against salt mist corrosion.

- Structural Adhesives and Sealants: The seal between the frame and the glass-laminate package must be exceptionally durable. High-grade sealants are essential to prevent moisture ingress and delamination under the flexing stress of hurricane-force winds.

- Optional Rear Support Bars: For maximum security in the most exposed locations, support bars can be fixed across the rear of the module frame to further prevent flexing and potential microcracking of the solar cells.

These design choices are fundamental to the long-term bankability of a solar asset in this environment.

Combating Corrosion and Humidity-Induced Degradation

Beyond the immediate physical threat of cyclones, the pervasive salt mist and high humidity pose a long-term risk to module performance and lifespan.

Salt Mist Corrosion

Salt-laden moisture accelerates the corrosion of metal components, compromising the module frame, junction box connections, and mounting structure. To mitigate this, modules designed for the Comoros should feature:

- High-Quality Anodized Frames: A thick and properly applied anodized coating on the aluminum frame is the first line of defense.

- IP67 or IP68 Rated Junction Boxes: The junction box protects the module’s electrical connections. A high Ingress Protection (IP) rating ensures it is sealed against both dust and moisture, preventing corrosion of the critical bypass diodes and terminals within.

Potential-Induced Degradation (PID)

High humidity, combined with high temperatures and system voltages, can trigger Potential-Induced Degradation (PID), a phenomenon that causes a gradual and significant loss of power output over time. Using PID-resistant materials, including specialized encapsulants and high-quality solar cells, is essential for maintaining performance in a tropical climate.

For investors, requiring modules with IEC 61701 certification (salt mist corrosion testing) provides third-party validation of their suitability for a maritime environment.

Designing for Off-Grid and Mini-Grid Applications

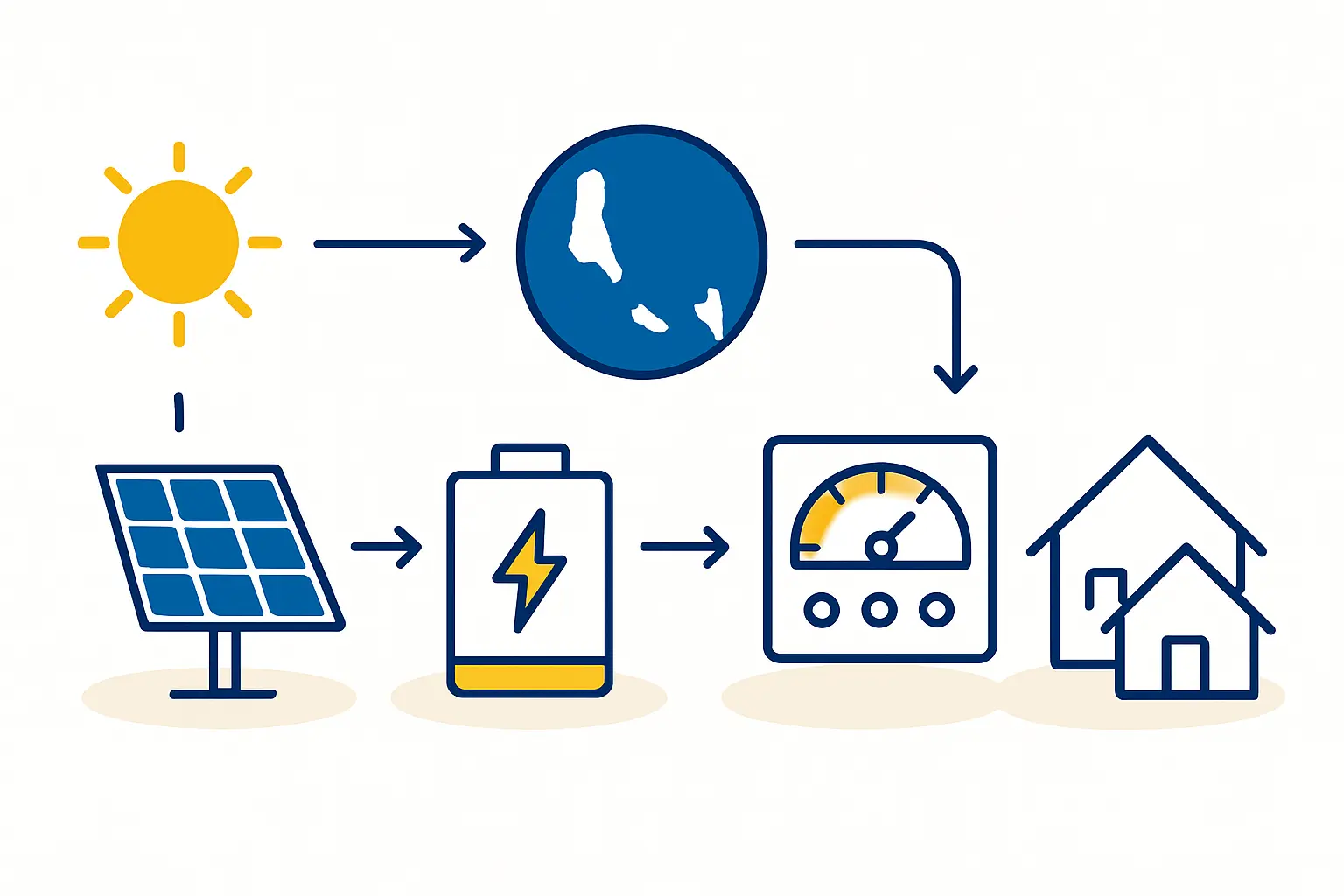

Given the state of the central grid, the most immediate opportunity in the Comoros lies in off-grid and mini-grid systems for rural electrification and grid stability. These applications have different requirements than large-scale, grid-tied solar farms.

Reliability is the highest priority, as a module failure in a remote village is not easily rectified. Modules for these applications must be exceptionally robust, making the design considerations for cyclone and humidity resistance all the more critical.

Furthermore, these systems often incorporate battery storage, requiring modules that perform predictably and reliably to ensure proper charging and management of the battery bank—often the most expensive component of the system. High-quality bypass diodes inside the module’s junction box are also critical for mitigating power loss from partial shading, a common issue in small, distributed installations.

The Business Opportunity for Localized Manufacturing

Producing or specifying modules with these enhanced features presents a clear competitive advantage. While their upfront cost may be higher than a standard module, their long-term value proposition is far superior. A module purpose-built for the Comorian climate offers a lower levelized cost of energy (LCOE) due to its longer operational lifespan and higher reliability, reducing maintenance and replacement costs.

This creates a clear path for entrepreneurs considering market entry. A successful solar module manufacturing business plan will focus on producing modules that meet these specific regional needs. A local or regional turnkey solar manufacturing line can be configured to incorporate these specifications from the outset.

The selection of the right solar panel manufacturing machines—from laminators that ensure perfect sealing to framers capable of handling thicker profiles—directly impacts the final product’s quality and durability. Based on experience from J.v.G. turnkey projects in similar climates, focusing on a high-quality, resilient product builds a stronger brand and ensures greater project success.

Frequently Asked Questions (FAQ)

Q: What is the primary cause of solar module failure in coastal regions?

A: The primary causes are corrosion and moisture ingress. Salt mist corrodes metal frames and electrical connections, while high humidity can penetrate seals, leading to delamination and electrical faults like Potential-Induced Degradation (PID).

Q: Are cyclone-resistant modules significantly more expensive?

A: They have a moderately higher upfront cost due to more robust materials like thicker glass and stronger frames. However, this investment is easily recovered through a much longer service life and by avoiding replacement costs after a severe weather event. Ultimately, their long-term cost is considerably lower.

Q: Can a standard solar panel be used in the Comoros?

A: While a standard panel will produce power initially, its use is not advisable. It is highly susceptible to rapid degradation from salt mist and humidity and is unlikely to survive a major cyclone, making it a poor long-term investment.

Q: What certifications are most important for modules in this market?

A: Beyond the baseline IEC 61215 and IEC 61730 certifications, investors should look for IEC 61701 (salt mist corrosion testing) and evidence of enhanced mechanical load testing (often exceeding 5400 Pa) to verify durability against high wind loads.

A Strategic Path Forward

Success in the Comorian solar market is not about finding the cheapest module, but the most resilient one. Entrepreneurs and investors who recognize and address the region’s specific climatic and infrastructural challenges will be best positioned to build profitable, long-lasting energy projects.

By focusing on superior design and materials, a solar manufacturing venture can deliver a product that provides genuine energy security and a strong return on investment.