Imagine a newly commissioned solar module factory in Moroni, ready for its inaugural production run. State-of-the-art lamination and stringer machines hum in anticipation. Suddenly, the power cuts out.

The entire production line grinds to a halt—not for a few minutes, but for hours. For industrial investors in Comoros, this scenario isn’t a hypothetical risk; it’s a daily operational reality. In a capital-intensive venture like solar manufacturing, such instability is more than an inconvenience—it’s a direct threat to profitability and viability.

This article makes the case for an independent, resilient power supply for any solar factory in Comoros, exploring the practical solutions that can transform energy from a critical vulnerability into a controlled, strategic asset.

Table of Contents

The Power Dilemma in Comoros: A Challenge for Industrial Operations

To appreciate the need for energy independence, it helps to understand the local context. According to a 2022 assessment by the International Renewable Energy Agency (IRENA), the Union of the Comoros faces significant energy challenges that directly impact industrial operations:

- High Reliance on Fossil Fuels: Over 95% of the nation’s electricity comes from imported diesel fuel, creating exposure to volatile global fuel prices and supply chain disruptions.

- Expensive Electricity: The cost of grid electricity is exceptionally high, with medium-voltage industrial tariffs around USD 0.29 per kilowatt-hour (kWh). This places a substantial burden on a factory’s operational expenditure (OPEX).

- Chronic Unreliability: The national grid, managed by SONELEC, suffers from frequent power outages, load shedding, and poor power quality, including voltage and frequency fluctuations. These issues can damage sensitive manufacturing equipment and lead to costly production downtime.

Entrepreneurs planning industrial projects often focus on the production machinery itself, but experience from J.v.G. turnkey projects shows that underestimating local infrastructure, particularly power, is a common and costly oversight. A successful factory requires a power solution designed for resilience, not reliance—a critical factor for any detailed feasibility study.

Designing a Resilient Power System for Your Factory

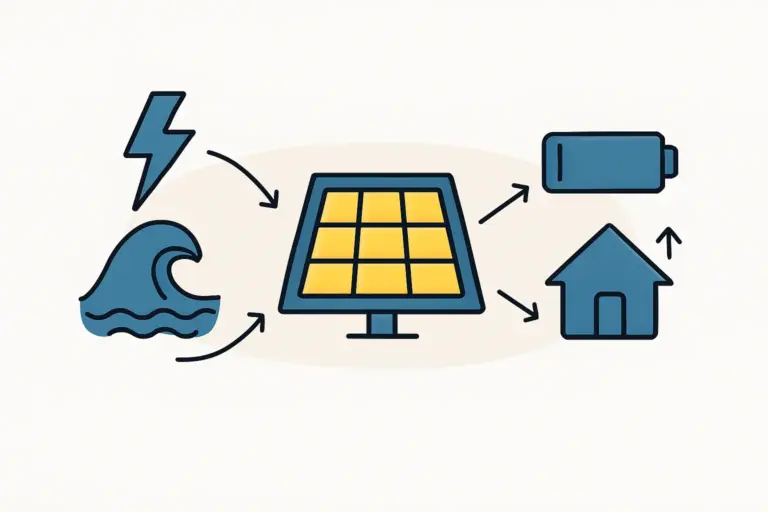

The most effective strategy for a solar factory in Comoros is to achieve energy self-sufficiency with a dedicated hybrid power system. This approach means creating an on-site microgrid that prioritizes reliability and cost control, built around three core components.

Primary Power Source: A Dedicated Solar PV Array

The most logical power source for a solar module factory is its own product. Installing a dedicated, ground-mounted or rooftop solar photovoltaic (PV) array allows the facility to generate its own clean electricity during daylight hours.

Given Comoros’ high levels of solar irradiation, this is both a technically sound and economically advantageous solution. For a factory with an annual production capacity of 20–50 MW, an on-site solar plant of approximately 1-2 MW is typically needed to cover a significant portion of its energy demand.

Energy Storage: The Role of a Battery Energy Storage System (BESS)

A solar array alone cannot power a factory 24/7. A Battery Energy Storage System (BESS) is the critical link that ensures continuous operation. A BESS is an industrial-scale battery solution that:

- Stores excess solar energy generated during the day for use at night or during overcast weather.

- Provides seamless backup power the instant a grid failure is detected, preventing any interruption to production.

- Stabilizes power quality by smoothing out fluctuations, protecting sensitive machinery.

solar PV system with a battery energy storage system (BESS) container, illustrating a self-sufficient power solution.”/>

solar PV system with a battery energy storage system (BESS) container, illustrating a self-sufficient power solution.”/>A BESS with a capacity of 2-4 megawatt-hours (MWh) would likely be sufficient for a medium-sized factory, ensuring operations can continue through the night and during brief periods of low solar generation.

Backup Power: The Diesel Generator as a Final Safeguard

While the solar and BESS combination covers the vast majority of the factory’s needs, a pragmatic approach to risk management includes a final layer of backup. A diesel generator serves as this ultimate safeguard.

Its purpose is not daily use but emergencies, such as prolonged periods of inclement weather or scheduled maintenance on the BESS. This approach keeps the factory operational, even in the worst-case scenarios.

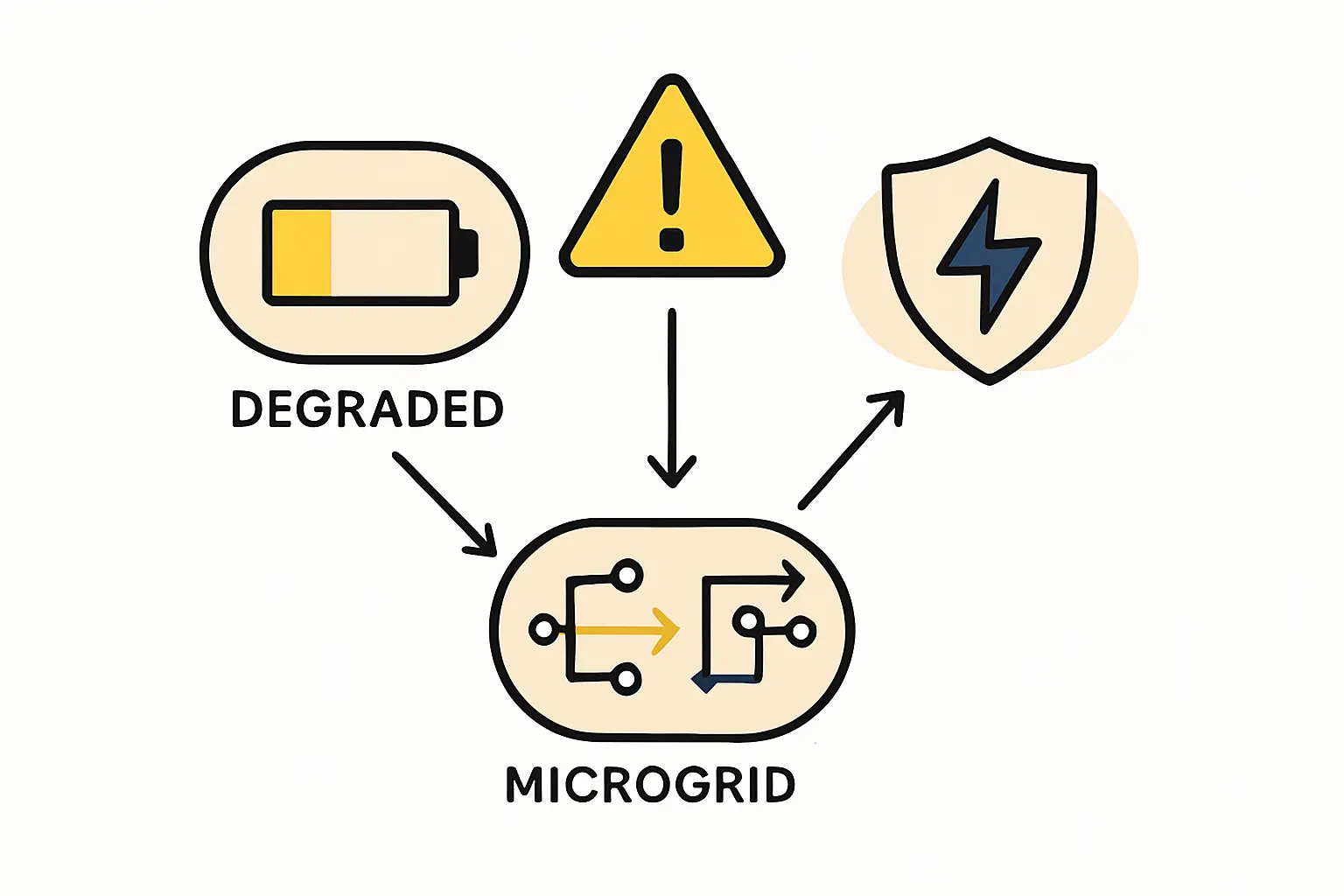

Integrating the Components: The Factory Microgrid Concept

These three components—solar PV, BESS, and a backup generator—are integrated and managed through a central control system to form a microgrid. A microgrid is a private, localized energy grid that can operate completely independently from the national utility, also known as “island mode.”

This setup offers complete control over the factory’s power supply. The system can be configured to:

- Prioritize self-generated solar power.

- Use stored battery energy during high-demand periods or at night.

- Automatically start the backup generator if battery levels fall below a critical threshold.

- Optionally connect to the main grid to draw power only if it is stable and economically viable.

This level of control is essential for protecting the investment in the manufacturing line. The physical layout and infrastructure for this power system are also key considerations in the overall building and site requirements for a solar module factory.

The Business Case: From Operational Cost to Strategic Asset

While an on-site microgrid represents a significant capital expenditure, it’s better viewed not as a cost, but as a strategic investment that delivers tangible returns.

- Operational Certainty: This approach eliminates production losses caused by an unstable grid, guaranteeing manufacturing uptime and predictable output.

- Cost Control: It insulates the factory from the high and volatile costs of grid electricity and diesel fuel. After the initial investment, the primary energy source—sunlight—is free. A client in a similar grid-constrained region found that their on-site power system not only guaranteed 99.9% uptime but also delivered a return on investment within seven years by eliminating utility bills and diesel costs.

- Asset Protection: Stable, high-quality power prevents premature wear and damage to sensitive, multi-million dollar manufacturing equipment.

By taking control of its energy supply, the factory transforms a major external risk into a manageable internal system and gains a decisive competitive advantage.

Frequently Asked Questions (FAQ)

Q: How much space is needed for such a power system?

A: The space required depends on the system’s size. A 1 MW solar array typically needs approximately 1 to 1.5 hectares (2.5 to 3.7 acres) of land for a ground-mounted installation. The BESS and generator are typically housed in containers or a small, dedicated building.

Q: Can this system sell excess power back to the grid?

A: While technically possible, the regulatory framework for selling power back to the SONELEC grid in Comoros may be underdeveloped. The primary business case for this system is built on self-sufficiency and operational resilience, not on exporting power. The focus should remain on ensuring the factory’s stability first.

Q: What is the typical investment for a factory power system?

A: The cost is highly dependent on the factory’s energy consumption, desired level of autonomy, and local logistics. For a 20–50 MW solar module factory, the on-site power infrastructure can represent a significant investment, potentially in the range of USD 1-3 million. This needs to be accurately calculated during the project planning phase.

Q: How long does it take to implement this power solution?

A: The process of engineering, procuring, and installing a microgrid of this scale typically takes between 6 and 12 months. This work should be planned and executed in parallel with the construction of the main factory building to ensure it is ready for commissioning.

Conclusion and Next Steps

For any entrepreneur planning to establish a solar module factory in Comoros, addressing the energy challenge is not optional—it is fundamental. Relying on the local grid introduces an unacceptable level of operational and financial risk.

Investing in a dedicated on-site microgrid—combining solar PV, battery storage, and a backup generator—is the key to achieving energy independence. This strategy ensures production continuity, protects valuable equipment, and provides long-term control over one of the most significant operational costs.

This power infrastructure is just one critical part of setting up a turnkey solar module production line, but it’s a component that can make or break the venture. Navigating these complex technical and logistical decisions is where structured guidance platforms like pvknowhow.com can help, providing support from the earliest stages of planning.