The Union of the Comoros faces a significant energy challenge. With over 90% of its electricity generated from expensive imported fossil fuels, the nation has one of the highest electricity costs in Africa. For an entrepreneur, this presents a clear opportunity: establishing a local solar module manufacturing plant would address a critical need, create economic value, and help build national energy independence.

The success of such a venture, however, hinges not on machinery alone, but on the people who operate it.

Many investors assume that a lack of prior industrial experience in a region is an insurmountable barrier. Yet, the opposite is often true. With a population of over 850,000 and a median age of just 20.4 years, Comoros has a vast, untapped reservoir of young, motivated individuals. The key is not to find pre-trained experts, but to implement a structured system for developing them. This guide outlines a practical framework for sourcing, training, and managing a local workforce for a solar module factory in the Comoros.

Table of Contents

Understanding the Comorian Labor Landscape

A successful recruitment strategy must be grounded in the local context. The Comorian labor market has several distinct characteristics that an investor can leverage.

A Young and Available Workforce

The country’s youth unemployment rate (for ages 15-24) stands at approximately 19.3%. This represents a significant pool of potential candidates eager for stable, long-term employment in a new and growing industry.

A Strong Educational Foundation

With a literacy rate of nearly 82%, the general population has a solid foundation for learning technical material and safety protocols. This is a crucial advantage when building a competent operational team from the ground up.

Economic Context

The primary sectors of the Comorian economy are agriculture, fishing, and forestry. While this means direct experience in industrial manufacturing is rare, it also makes a well-structured factory job a highly attractive proposition. The challenge isn’t a lack of willingness, but the need to introduce concepts like industrial discipline, quality control, and process adherence.

These factors combine to create a favorable environment for an investor prepared to treat human capital development as a core part of the business plan.

Core Roles in a Solar Module Production Line

A semi-automated solar module factory runs on a team with distinct yet complementary skills. A typical facility with a 20-50 MW annual capacity requires a workforce of 25 to 40 individuals, generally divided into three main categories.

Machine Operators

This group forms the backbone of the production workforce. Operators are responsible for running specific stations along the assembly line, such as the solar cell stringer, lay-up station, laminator, and framing machine. These roles are process-driven and rely on precision and consistency. For most operator positions, a strong work ethic and attention to detail are more critical than prior technical experience.

Technicians

Technicians handle equipment maintenance, troubleshooting, and quality control. Their duties range from ensuring machines run within specified parameters to performing regular checks on materials and finished products. Ideal candidates for these roles may come from local vocational schools or have a demonstrated aptitude for mechanical or electrical systems. They will require more in-depth training on the plant’s specific machinery, making a fundamental understanding of the step-by-step solar panel manufacturing process essential.

Supervisors and Management

This tier oversees daily operations, manages shift schedules, and ensures production targets and quality standards are met. A plant manager or production supervisor must possess both leadership skills and a solid technical understanding of the entire manufacturing process. Initially, this role may be filled by an expatriate expert whose primary function is to train a local successor. This knowledge transfer is a critical step for anyone learning how to start a solar panel business and ensure its long-term, local success.

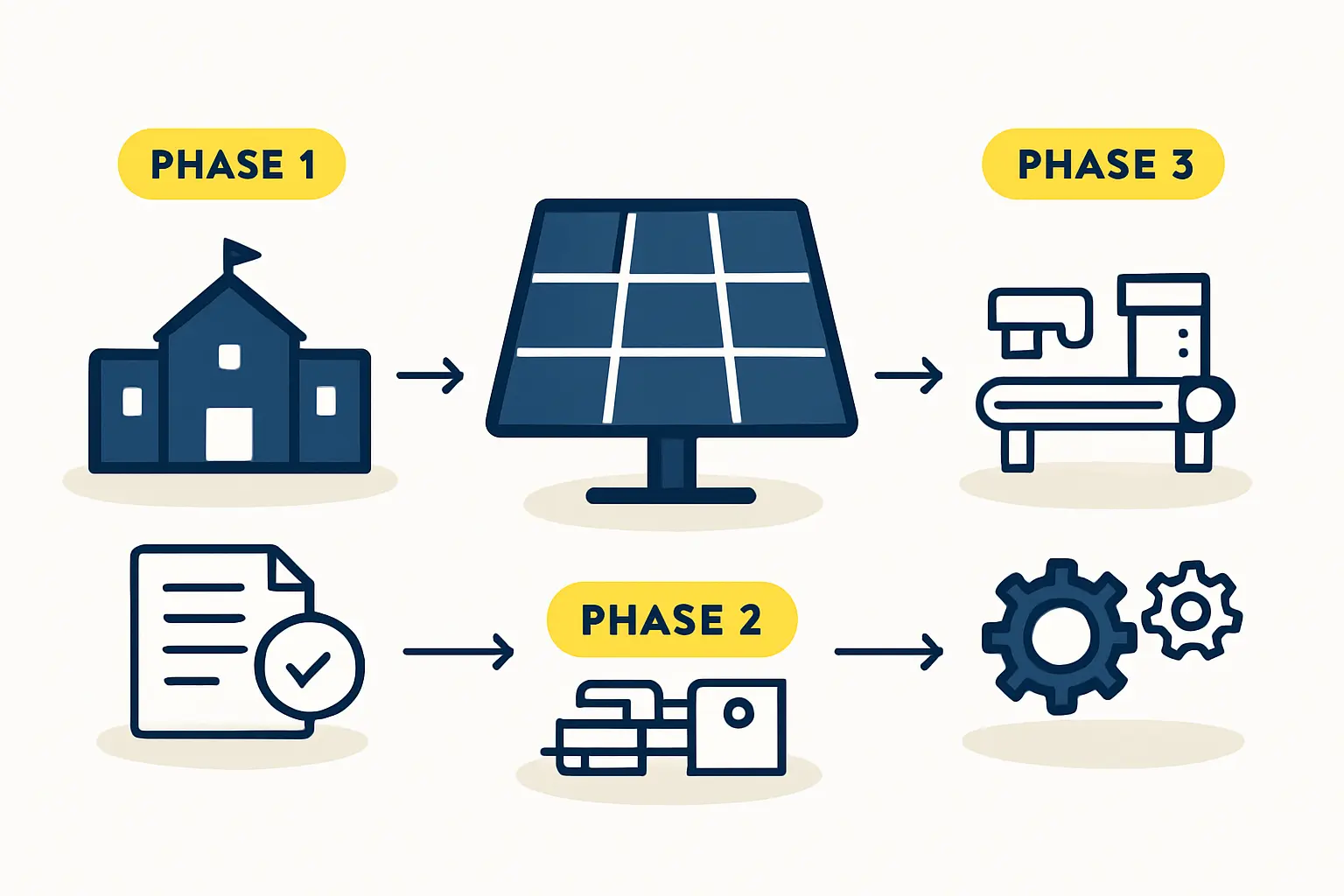

A Phased Approach to Recruitment and Training

Building a skilled team from scratch requires a methodical, multi-phase approach that begins long before the factory is operational.

Phase 1: Sourcing and Selection

Initial recruitment should focus on identifying individuals with high potential. Rather than seeking specific solar experience, the selection criteria should prioritize aptitude, reliability, and a capacity to learn.

Recruitment Channels: Collaborate with the University of the Comoros and local vocational training centers. Post openings in community hubs and use local radio to announce opportunities. A transparent, merit-based selection process will build goodwill from the outset.

Assessment: Use simple, practical tests to gauge dexterity, problem-solving skills, and the ability to follow multi-step instructions. For technician and supervisor roles, look for foundational knowledge in electrical or mechanical fields.

Phase 2: Foundational Classroom and Workshop Training

This critical phase occurs before the main production equipment is fully installed, bridging the gap between a non-industrial background and the demands of a modern factory.

Core Curriculum: Training should cover workplace safety, the basic principles of photovoltaics, the importance of quality control, and an introduction to manufacturing processes.

Practical Simulation: Experience from J.v.G. Technology GmbH turnkey projects shows that hands-on practice in this phase is invaluable. Simple mock-ups of workstations can be used to teach the proper handling of materials like solar cells and glass, minimizing waste and errors once live production begins.

Phase 3: On-the-Job Training with Expert Guidance

Once the production line is commissioned, training becomes highly specific. This phase is best led by experienced engineers from the equipment supplier or a supervising consultant.

Machine-Specific Training: Each operator is trained extensively on their assigned station until they can run it safely and efficiently.

Developing Local Trainers: Identify the most capable local team members and provide them with advanced “train-the-trainer” instruction. These individuals will become the facility’s future training leaders, ensuring sustainable, in-house expertise.

Cross-Training: Over time, train operators on multiple machines. This creates a more flexible and resilient workforce, capable of covering for absences and adapting to changes in production flow.

Leveraging International Expertise for Local Development

For a new factory in an emerging market, it is unrealistic to expect to find all the necessary expertise locally from day one. A common and effective strategy is to employ a small team of expatriate experts—such as a plant manager and a lead maintenance technician—for the first 12 to 24 months of operation.

This team’s primary objective must be knowledge transfer: systematically training their local counterparts to take over. A clear succession plan should be in place, with performance metrics tied to the successful training of local replacements. This model ensures the plant achieves international quality standards from the beginning while building a completely self-sufficient local team for the long term.

Overcoming Potential Challenges

Proactively addressing a few key challenges is crucial for success.

Language Barriers

Technical manuals for machinery are often in English or Chinese. While French is an official language in Comoros, investing in the translation of key documents and safety procedures is wise. Hiring bilingual supervisors can also bridge communication gaps between expatriate trainers and local staff.

Developing an Industrial Culture

For a workforce accustomed to agricultural or informal work cycles, the structured environment of a factory can be a significant adjustment. Management must actively cultivate a culture of punctuality, safety, and accountability through clear communication and by consistently upholding company standards.

Employee Retention

As employees develop new skills, they become valuable assets. Retaining them requires offering competitive compensation, a safe work environment, and clear pathways for career advancement. Factoring this into the initial solar panel manufacturing plant cost analysis is a prudent step.

Frequently Asked Questions (FAQ)

Q: How many employees are needed for a small-scale solar factory in Comoros?

A: A typical semi-automated production line with an annual capacity of 20 to 50 MW generally requires 25 to 40 people, including operators, technicians, supervisors, and administrative personnel, often split across two shifts.

Q: Do we need to hire university-educated engineers for all technical roles?

A: No. While a lead engineer or plant manager may hold a university degree, most technician and operator roles are better suited to individuals with vocational training or strong mechanical aptitude. On-the-job training is far more critical than formal academic qualifications for the majority of the workforce.

Q: How long does it typically take to train a new machine operator?

A: For a dedicated individual, basic proficiency on a single machine can usually be achieved within 4 to 8 weeks of intensive, hands-on training under expert supervision. Becoming a highly efficient operator may take several months.

Q: Can a factory in Comoros rely solely on local talent from day one?

A: While the long-term goal is 100% local staffing, it is highly advisable to have a small team of external experts on-site for the initial setup, commissioning, and training period (typically 6-18 months). This ensures that best practices for quality and efficiency are established correctly from the beginning.

Conclusion

Ultimately, establishing a solar module factory in Comoros is an investment in human capital as much as it is in machinery. The nation’s young, literate, and motivated population is a strategic asset. With a well-designed and patient approach to training and development, an investor can build a world-class manufacturing team that not only produces high-quality solar modules but also creates lasting economic opportunity for the local community.