An entrepreneur looking across Eritrea’s vast, sun-drenched landscapes sees an undeniable opportunity. With some of the highest solar irradiation levels in the world, the potential for solar energy is immense.

Yet a critical oversight can undermine a new solar venture from the start: assuming that a standard module, designed for temperate European climates, will perform effectively and reliably in the extreme heat and dust of the Horn of Africa.

Environmental conditions directly impact a solar module’s power output and lifespan. A production line configured for standard modules will likely turn out products ill-suited for the local market, leading to underperformance and premature failure. This article breaks down the technical considerations for designing a solar module production line for challenging climates like Eritrea’s, ensuring the final product is both durable and efficient.

The Environmental Challenge: Heat and Dust

A successful product starts with a clear understanding of the challenges it must overcome. For solar modules in Eritrea, two primary environmental stressors dictate design and material choices: extreme ambient temperatures and the prevalence of abrasive dust.

The Impact of High Temperatures on Module Performance

Every solar module has a “temperature coefficient of Pmax,” a technical term for how much power the module loses for every degree Celsius the temperature rises above the standard test condition of 25°C. In a region where daytime temperatures can frequently exceed 40°C, a module’s operating temperature can reach 70-80°C or even higher.

To put this in business terms, a typical solar module with a temperature coefficient of -0.45%/°C operating at 75°C (50°C above standard) will experience a power loss of approximately 22.5%. For a 400-watt panel, this means it would produce only around 310 watts during the hottest parts of the day. This is not a defect; it is physics.

However, selecting cells and materials with a better temperature coefficient (e.g., -0.35%/°C) can significantly mitigate these losses, preserving more of the module’s output and increasing its energy yield over a lifetime.

The Problem of Dust and Soiling

In arid and semi-arid regions, dust accumulation, or “soiling,” is a major operational issue. A layer of dust on a module’s surface can block sunlight from reaching the solar cells, directly reducing energy production. Studies in similar climates show that soiling can decrease a module’s output by 10-20% or more in just a few weeks without regular cleaning.

Windblown sand can also be abrasive, potentially damaging the module’s surface over time. This underscores the need for durable front glass with specific coatings that not only maximize light transmission but also resist abrasion and simplify cleaning.

Key Material Selections for a Climate-Resilient Module

A solar module is an assembly of carefully selected components. When setting up a turnkey solar production line for a market like Eritrea, specifying the right materials from the outset is essential for creating a premium, climate-appropriate product.

Encapsulants: Protecting the Solar Cells

The encapsulant is a polymer layer that bonds the solar cells to the glass and the backsheet, protecting them from moisture, mechanical stress, and thermal cycling.

-

Ethylene Vinyl Acetate (EVA) is the industry standard due to its low cost. However, standard EVA can be prone to degradation and discoloration (yellowing) under prolonged exposure to high temperatures and intense UV radiation, which reduces the amount of light reaching the cells.

-

Polyolefin Elastomer (POE) is a more advanced alternative that offers superior resistance to heat, humidity, and UV degradation. It also provides better long-term electrical insulation properties. For a hot climate, specifying POE is a strategic decision that enhances the module’s longevity and reliability, even if it represents a slightly higher initial material cost.

Backsheets and Glass: The Module’s Armor

The choice between a traditional glass-backsheet design and a modern glass-glass construction has significant implications for durability in harsh environments.

-

Glass-Backsheet: This design uses a polymer backsheet as the rear layer. While cost-effective, the quality of the backsheet is paramount. Low-cost backsheets can become brittle and crack under intense thermal stress and UV exposure, allowing moisture ingress and leading to module failure.

-

Glass-Glass: A glass-glass module uses a second pane of glass for the rear layer. This design offers superior mechanical stability, fire resistance, and impermeability to moisture. It is exceptionally resistant to degradation from heat and UV, making it an excellent choice for desert climates. The manufacturing process for glass-glass modules requires specific handling and lamination parameters.

Frames and Junction Boxes: Securing the Perimeter

The module’s aluminum frame provides structural integrity, while the junction box houses the bypass diodes and electrical connections. In a dusty environment, the quality of these components is crucial. A well-designed frame and a properly sealed junction box (rated IP67 or IP68) prevent the ingress of fine dust and moisture, which can cause short circuits and corrosion over time.

Adapting the Manufacturing Process

Specifying superior solar module components is only half the battle; the production line must be configured to handle them correctly.

Lamination Process Adjustments

The laminator is the heart of the module production line, where the different layers are fused under heat and pressure. Different materials require different processing parameters; for instance, POE typically requires a different temperature profile and longer cycle time in the laminator compared to EVA. A turnkey line supplier with experience in these materials, such as J.v.G. Technology, can configure the machinery and process recipes to ensure a perfect, void-free lamination every time.

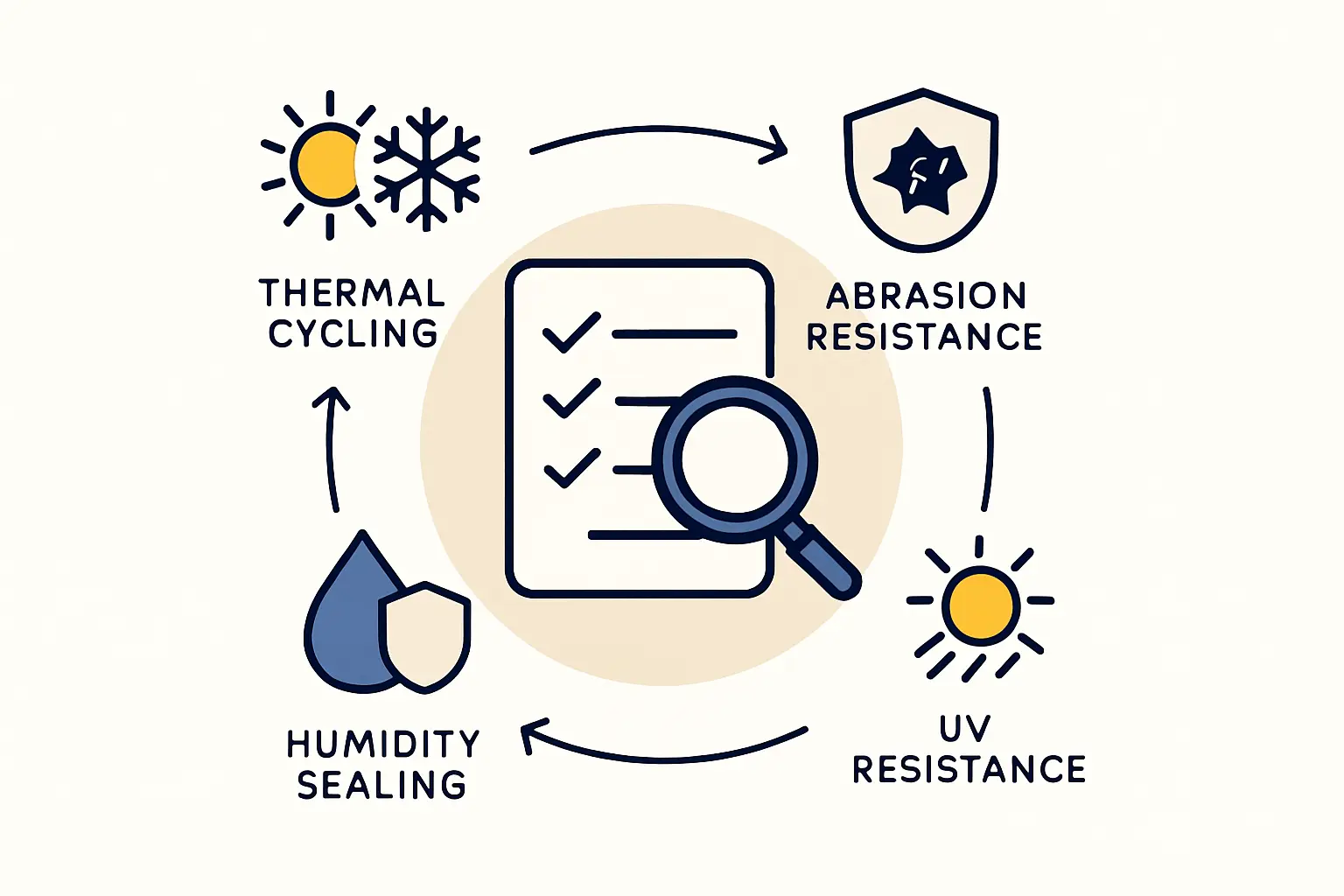

Emphasis on Quality Control

Manufacturing for a demanding climate requires a rigorous approach to quality control in solar manufacturing.

-

Electroluminescence (EL) Testing: This process functions like an X-ray for the solar module, revealing hidden microcracks in the solar cells. These cracks, invisible to the naked eye, can be created during cell handling or stringing and may expand under the stress of daily temperature fluctuations, leading to power loss years later. Implementing EL testing before and after lamination is a critical step to ensure long-term durability.

-

Climate Chamber Testing: While full certification testing is extensive, an in-house climate chamber allows for batch testing. Modules can undergo accelerated stress tests, such as “damp heat” and “thermal cycling,” to verify that the chosen materials and manufacturing processes yield a truly resilient product.

Frequently Asked Questions (FAQ)

Q1: What is the single most important factor when manufacturing modules for a hot, arid climate?

There is no single factor; it is a holistic approach. However, managing heat is paramount. This involves selecting solar cells with a good temperature coefficient and using materials like POE encapsulant and glass-glass constructions that can withstand long-term thermal stress without degrading.

Q2: Are glass-glass modules always the better choice for desert environments?

They offer superior durability and longevity, making them an excellent technical choice. However, they are slightly heavier and may have a higher initial production cost. A high-quality glass-backsheet module using a top-tier, climate-proven backsheet can also perform well. The decision often involves balancing project budget with long-term performance requirements. Based on experience from J.v.G. turnkey projects, the trend in demanding climates is moving toward glass-glass.

Q3: How much does it cost to produce climate-adapted modules compared to standard ones?

The initial material cost for components like POE or a second pane of glass may increase the bill of materials (BOM) by a few percent. However, this marginal increase in production cost yields a product with a significantly higher market value, greater energy yield, and a longer reliable lifespan. This leads to a better reputation and a stronger business case in the long run. The investment requirements for a solar factory should account for this from the planning stage.

Q4: Can an existing production line be upgraded to handle these specialized materials?

Yes, in many cases. An upgrade may involve recalibrating the laminator for new process recipes, adjusting handling equipment for glass-glass modules, and enhancing quality control stations. A technical audit can determine the exact requirements for such an upgrade.

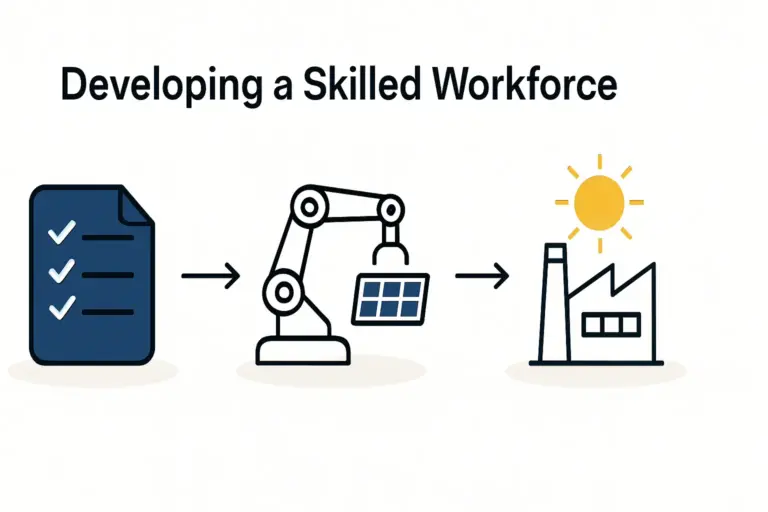

Building a Resilient Local Solar Industry

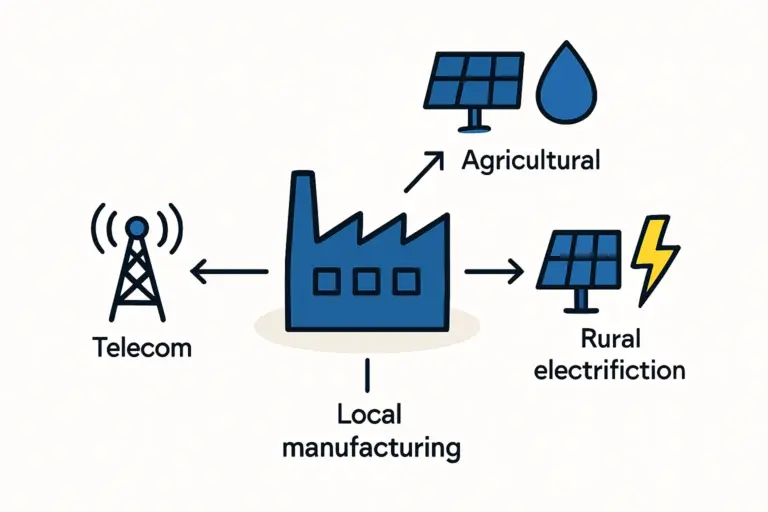

Success in Eritrea’s emerging solar market will not come from simply assembling imported components. It will be driven by entrepreneurs who understand the local environmental challenges and invest in a manufacturing setup built to overcome them.

By carefully selecting materials and fine-tuning production processes, a local factory can produce solar modules that outperform standard imports, offer a longer lifespan, and deliver a better return on investment for the customer. This approach transforms a manufacturing plant from a simple assembly line into a center for technical excellence, capable of building a trusted local brand and contributing meaningfully to the nation’s energy future.

With the right planning and expert guidance, this vision is well within reach.