An investor considering a new solar module factory often focuses first on capital, machinery, and market access. However, experience from numerous turnkey projects has shown that the availability and quality of the local labor force are equally critical—and often underestimated—factors for success.

In a country like Ethiopia, with its large, young population and ambitious industrialization goals, the potential seems immense. The key question is not whether labor is available, but whether the right skills are accessible.

This analysis examines Ethiopia’s technical labor landscape for solar module assembly, offering a realistic assessment of the existing skill base, the role of vocational training institutions, and practical strategies for developing a capable workforce for a new manufacturing enterprise.

The Ethiopian Labor Landscape: A High-Level Overview

Ethiopia presents a compelling, albeit complex, demographic picture for industrial investors. The country has one of the youngest populations in Africa, with over 40% of its more than 120 million people under the age of 15. This creates a vast pool of potential workers entering the labor market each year.

Key statistics provide context:

- Youth Population: A significant demographic dividend is available if this workforce can be effectively trained and employed.

- Government Focus: The Ethiopian government’s industrialization strategy actively promotes manufacturing, including sectors related to renewable energy, as part of its Homegrown Economic Reform Agenda.

- Unemployment: While official figures vary, youth unemployment remains a significant challenge, indicating a ready supply of individuals seeking stable employment opportunities.

However, this large labor pool consists predominantly of individuals from agricultural or general service backgrounds. The specific technical skills required for modern manufacturing, particularly in a precision-focused industry like solar PV assembly, are not widespread. This disparity creates a gap between labor availability and industrial readiness.

Evaluating Technical and Vocational Education and Training (TVET)

The primary channel for developing technical skills in Ethiopia is the Technical and Vocational Education and Training (TVET) system. The government has invested significantly in expanding TVET institutions across the country, aiming to produce a skilled workforce capable of supporting industrial growth.

These institutions provide foundational training in areas such as:

- General mechanics

- Electrical installation and maintenance

- Metalwork and welding

- Industrial automation basics

While TVET graduates possess a valuable theoretical foundation and a degree of technical aptitude, investors should not expect them to be ‘plug-and-play’ employees for a solar module factory. A critical gap often exists between the general curriculum of a TVET program and the specialized, process-driven skills needed for photovoltaic assembly. For example, a graduate may understand electrical principles but will have no experience operating a solar cell stringer or an electroluminescence (EL) tester.

This reality is not a barrier but a crucial planning parameter. A successful human resources strategy must include a robust post-hiring training program to bridge this specific skills gap.

Key Skill Sets for Solar Module Assembly

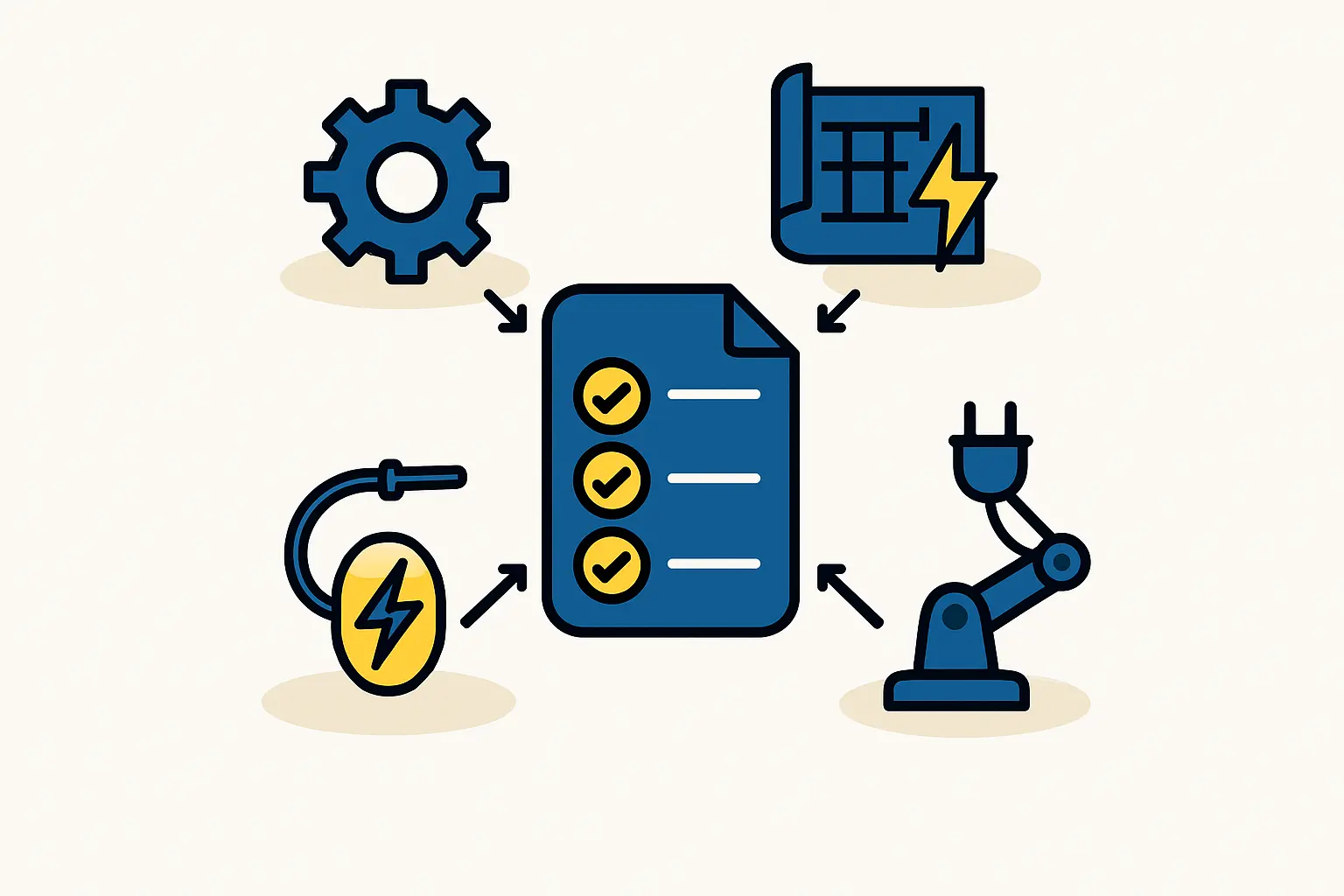

A semi-automated solar module assembly line does not require a large team of highly qualified engineers; rather, it relies on a well-structured team with distinct roles. Understanding these roles is key to assessing the local talent pool. An investor will primarily need to source and develop talent for the following positions:

-

Machine Operators: These individuals form the core of the production team, responsible for running specific machines like the stringer, layup station, and laminator. The ideal candidate is detail-oriented, consistent, and capable of following precise instructions. Skills from other precision assembly industries, such as electronics or even textiles, can be highly transferable.

-

Technicians: This role requires a higher level of technical understanding and is often a good fit for TVET graduates. Technicians handle machine setup, basic maintenance, and troubleshooting minor faults, ensuring that processes run within specified parameters. They act as the first line of defense against production downtime.

-

Quality Control (QC) Specialists: QC staff are responsible for inspection at various stages, from incoming raw materials to final module testing. They use specialized equipment like EL testers and sun simulators. This role demands a meticulous nature and the ability to interpret technical data.

-

Maintenance Engineers: A small team of one or two engineers with stronger mechanical and electrical backgrounds is needed for complex repairs, preventative maintenance schedules, and managing spare parts. They often have a diploma or degree in engineering.

When assessing candidates, practical aptitude and a willingness to learn are often more important than direct experience in the solar industry, which is nascent in Ethiopia. For a detailed breakdown of team structure and roles, it is helpful to review the typical labor requirements for a solar factory.

Strategies for Building a Skilled Workforce in Ethiopia

Given the skills gap, a proactive approach to workforce development is essential for operational success. The following strategies have proven effective in J.v.G. turnkey projects across emerging markets.

In-House Training Programs

The most critical element is a structured in-house training program, typically led by an experienced engineer or production manager—often an expatriate—during the first 6 to 12 months of operation. The program should include:

- Classroom Sessions: Covering the fundamentals of PV technology, quality standards, and safety protocols.

- On-the-Job Training: Supervised, hands-on practice on each machine, moving from basic operation to standard procedures and troubleshooting.

- Train-the-Trainer Model: The initial expert should focus on developing local team leaders and technicians who can then take over the training of new hires. This builds sustainable, in-house capability.

Partnering with Local Institutions

Engaging with local TVET colleges or technical universities can be a powerful long-term strategy. A company can offer to:

- Provide input on curriculum development to better align it with industry needs.

- Offer internships or apprenticeships for promising students.

- Guest lecture on the specifics of solar panel manufacturing.

This not only builds a future talent pipeline but also establishes the company as a leading technology employer in the region.

Sourcing Talent from Related Industries

Instead of searching for non-existent solar experience, a more effective approach is to identify industries with parallel skill requirements. Candidates with experience in electronics assembly, food processing (which often involves automated lines), or automotive component manufacturing often possess the necessary discipline, attention to detail, and familiarity with a factory environment. This approach significantly broadens the pool of potential hires.

The initial investment in training is a core component of setting up a solar module production line and should be factored into the project budget and timeline from the outset.

Case Insight: Overcoming the Initial Skill Gap

A common challenge in emerging markets is bridging the gap between theoretical knowledge and practical application. In one project, new hires from a local technical institute were proficient in reading electrical diagrams but struggled with the physical troubleshooting of a machine PLC (Programmable Logic Controller).

The solution was not more classroom theory but an intensive, two-month practical program. Led by an experienced German engineer, the program focused exclusively on hands-on fault simulation and recovery on the actual production machines. The local technicians diagnosed and fixed deliberately created errors under supervision. This practical, problem-solving approach rapidly built their confidence and real-world competence, turning them into a self-sufficient maintenance team within six months.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale (20–50 MW) assembly line?

A typical semi-automated line of this capacity operates with a team of 25–35 employees per shift, including operators, technicians, QC staff, and logistics personnel.

Is a university engineering degree necessary for all technical roles?

No. The majority of roles, including operators and QC inspectors, do not require a university degree. A diploma from a TVET institution is often sufficient for technician roles. Only one or two senior maintenance or production lead roles might require an engineering degree.

What is the typical duration for training new operators?

For someone with good mechanical aptitude, basic training to operate a specific machine under supervision can be completed in 2–4 weeks. Becoming proficient enough to work independently and handle minor issues typically takes 2–3 months.

How significant is the language barrier for technical staff?

While Amharic is the official language, a working knowledge of English is highly beneficial for team leaders, technicians, and engineers. Machine manuals, software interfaces, and communication with international equipment suppliers are almost always in English. This makes it a key hiring criterion for technical leadership roles.

Conclusion: The Path Forward for Investors

Ethiopia’s labor market offers significant potential for investors in solar module manufacturing. The country’s young, motivated population provides a solid foundation for building a productive workforce. However, success hinges on a clear-eyed assessment of the existing skills landscape and a deliberate strategy to bridge the gap between general technical education and the specific demands of a modern factory.

Investors should view the need for training not as a disadvantage, but as a fundamental part of the investment. By implementing robust in-house training programs, leveraging talent from adjacent industries, and potentially collaborating with local institutions, a company can develop a loyal, skilled, and cost-effective team. This methodical approach to human capital is a cornerstone of long-term success and is fundamental to how to start a solar panel factory.