The promise of solar energy is one of consistency and reliability, a crucial factor for any entrepreneur considering an investment. In regions like Fiji, however, located in the heart of the South Pacific cyclone belt, that promise is tested by some of nature’s most powerful forces. A standard solar module designed for temperate European or North American climates may not survive its first tropical cyclone.

This challenge also presents a distinct business opportunity: manufacturing solar modules specifically engineered to withstand the extreme weather of the Pacific. This article outlines the key technical requirements and manufacturing considerations for producing these cyclone-resistant solar modules—a critical component for building resilient and sustainable energy infrastructure in Fiji and similar regions.

The Challenge: Why Standard Solar Modules Fail in Cyclonic Conditions

A tropical cyclone places immense physical stress on any structure. For a solar module, the primary threats are not just high-speed winds, but the complex aerodynamic forces they generate.

-

Positive Wind Load: This is the direct pressure of wind pushing down onto the face of the module.

-

Negative Wind Load (Uplift): This is often the more destructive force. As wind flows over the module, it creates a low-pressure zone, similar to the principle that allows an airplane wing to generate lift. This suction force pulls the module upwards, attempting to tear it from its mounting and delaminate its components.

-

Oscillating Pressure: Rapid shifts in wind speed and direction cause the module to flex and vibrate, fatiguing materials and connections over time.

-

Debris Impact: Cyclones carry airborne debris, which can cause catastrophic impact damage to the module’s glass surface.

Standard solar modules are typically tested to withstand a static load of 2400 Pascals (Pa) for negative load and 5400 Pa for positive load. However, cyclonic winds in Fiji can generate forces far exceeding these thresholds, leading to frame failure, glass shattering, or the delamination of the entire module.

Engineering for Survival: Key Design Modifications

Creating a cyclone-resistant solar module isn’t about a single improvement, but a systematic reinforcement of its entire structure. The goal is to transform the module from a potential ‘sail’ into a rigid, unyielding component of the building envelope.

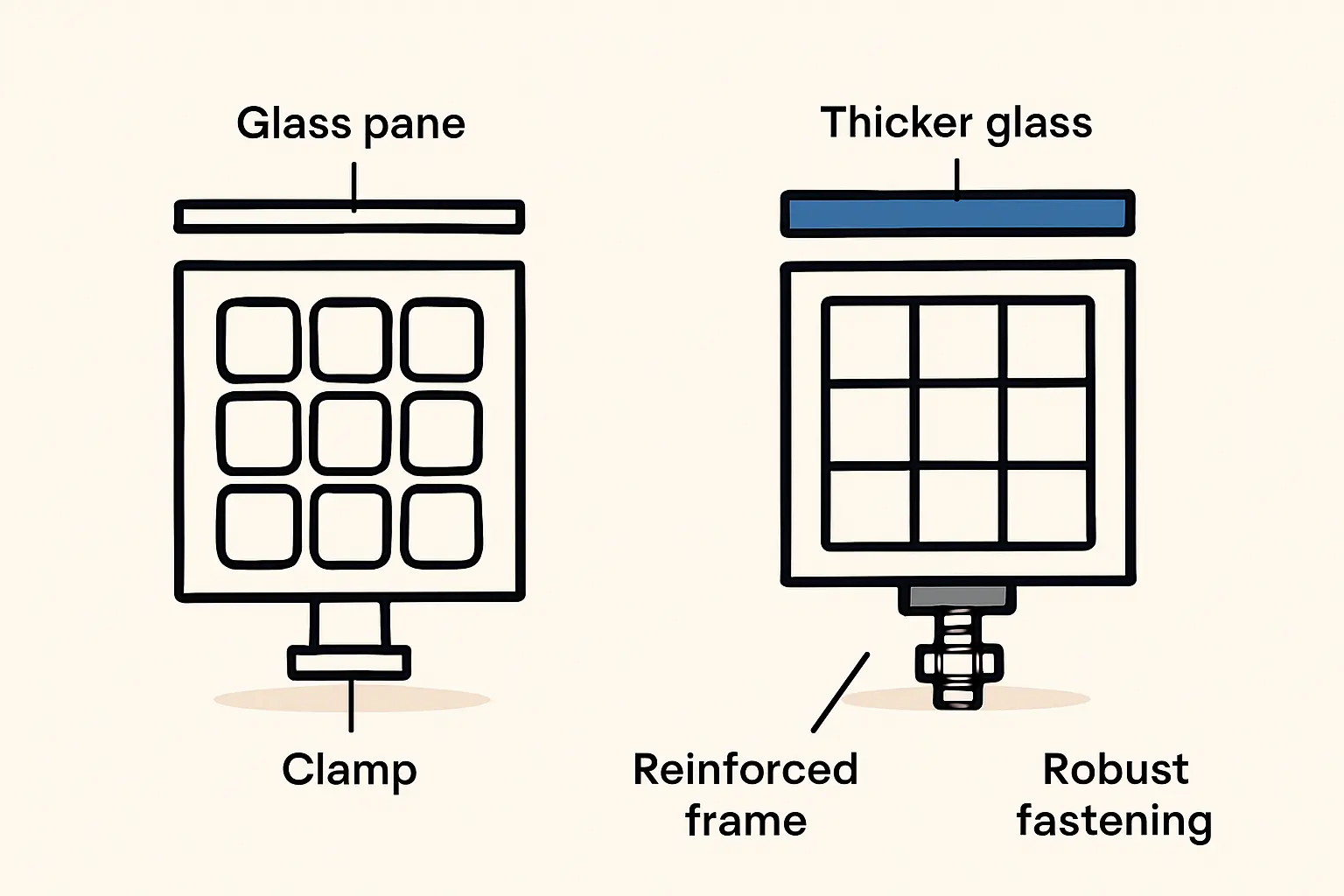

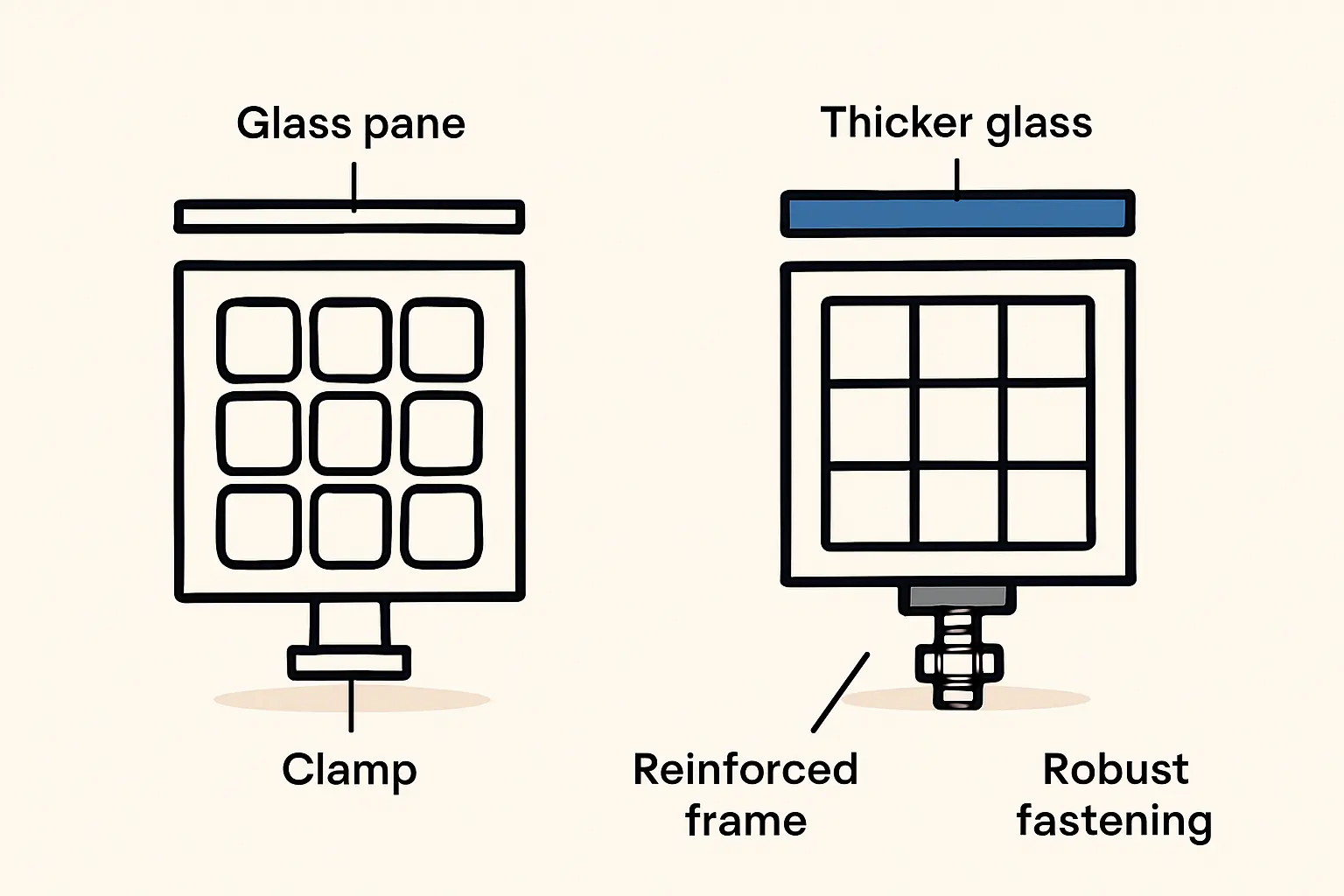

Reinforced Framing Systems

The aluminum frame is the module’s first line of defense, yet standard frames are often designed more to minimize material costs than to maximize strength. For high-wind applications, the frame must be significantly more robust.

-

Increased Thickness and Profile: The frame’s wall thickness is increased, and a double-walled or hollow-chamber profile is used. This dramatically improves its resistance to twisting (torsion) and bending under extreme pressure fluctuations.

-

Secure Corner Keys: The corners are a common point of failure. Stronger, more deeply set corner keys, often secured with additional bonding agents or mechanical fasteners, are essential to prevent the frame from deforming or separating.

Thicker, Tempered Glass

The front glass of a solar module not only protects the solar cells but also contributes significantly to its structural rigidity.

-

Increased Glass Thickness: The industry standard is typically 3.2mm tempered glass. For cyclonic regions, increasing this to 4.0mm or even 5.0mm provides a substantial boost in mechanical strength and resistance to impact from flying debris.

-

Heat Strengthening: While fully tempered glass is standard, some specialized modules may use heat-strengthened glass, which offers a different breakage pattern that can be advantageous in certain structural applications.

Enhanced Adhesion and Lamination

The layers of a solar module—glass, encapsulant, cells, and backsheet—are bonded together in a lamination process. Under severe uplift forces, the strength of this bond is critical.

A weak bond can lead to delamination, where the layers begin to separate, allowing moisture ingress and causing immediate failure. High-grade encapsulants with superior adhesive properties, such as specific types of POE instead of standard EVA, are therefore essential. This ensures the entire module acts as a single, unified composite structure that can resist separation.

From Design to Reality: Manufacturing and Material Considerations

These design enhancements carry over directly into the production process. An entrepreneur serving this market can’t rely on a standard equipment list; the entire solar module manufacturing line must be specified to handle these more robust materials.

For example, the automated framing machine must be calibrated for thicker, heavier frame profiles. The laminator’s heating and pressure cycles may need adjustment to properly cure the adhesives with 4.0mm glass. The selection of solar module components becomes less about cost per watt and more about long-term durability and certification compliance.

This level of customization is a core consideration when planning turnkey solar production lines for specialized markets. Aligning the machinery with the final product’s performance requirements from day one is essential for success, as experience from past J.v.G. projects demonstrates.

Proving Resilience: Certification and Testing Protocols

A claim of being “cyclone-resistant” is meaningless without objective proof. This proof comes from rigorous testing that simulates the forces of a cyclone in a controlled laboratory environment.

While the global benchmark for module safety and design is the IEC 61215 certification, its standard load tests may be insufficient for Fiji. The relevant standard for wind actions in the region is AS/NZS 1170.2 (Australian/New Zealand Standard for Structural Design Actions, Part 2: Wind Actions).

Modules intended for this market must undergo extended mechanical load testing. Instead of the standard 2400 Pa / 5400 Pa, they are subjected to significantly higher pressures, sometimes reaching 8000 Pa or more, to prove they can survive the extreme uplift and downforce pressures of a Category 5 cyclone. Passing these tests is a powerful market differentiator and often a requirement for insurance and project financing.

The Business Case for Localized, High-Resilience Manufacturing

For an entrepreneur in Fiji or a similar market, focusing on high-resilience modules offers several strategic advantages:

-

Address a Critical Local Need: It provides a product that is genuinely fit-for-purpose, enhancing the long-term viability of solar investments in the region.

-

Command a Premium: These modules have a higher bill of materials and a clear value proposition, justifying a higher price point.

-

Meet Regulatory and Insurance Requirements: As awareness of climate risk grows, building codes and insurance policies will increasingly mandate certified, cyclone-rated components for critical infrastructure.

-

Build a Trusted Brand: Becoming the local expert and provider of resilient solar technology builds a powerful brand reputation that imported standard products cannot match.

Frequently Asked Questions (FAQ)

What exactly is wind load?

Wind load is the force exerted on a structure by the wind, measured in Pascals (Pa). One Pascal is equivalent to one Newton of force per square meter. For solar modules, this includes both direct pressure (positive load) and suction or uplift forces (negative load).

Do these specialized modules cost significantly more to produce?

Yes, they have a higher production cost. The reinforced frames, thicker glass, and potentially specialized encapsulants increase the bill of materials. However, this cost increase is justified by the vastly improved durability and reduced risk of failure, leading to a lower total cost of ownership over the project’s lifetime.

Can a standard solar factory be retooled to produce cyclone-resistant modules?

It is possible, but it requires careful assessment. The framing station, laminator, and material handling systems must be capable of processing the heavier and larger components. It is far more efficient to design the production line for these specifications from the outset.

Is standard IEC 61215 certification enough for Fiji?

While IEC 61215 is a fundamental quality certification, its standard mechanical load tests (2400 Pa uplift) are generally not considered sufficient to demonstrate resilience against severe tropical cyclones. Specific, higher-pressure load testing is required to prove a module’s suitability for these high-risk environments.

Conclusion: Building a Foundation for a Sustainable Future

The transition to renewable energy in cyclone-prone regions like Fiji demands more than just deploying technology; it requires deploying the right technology. Manufacturing solar modules engineered for local climatic realities is not a niche consideration—it is fundamental to the long-term success and sustainability of the solar industry in the region.

For the forward-thinking entrepreneur, this represents an opportunity to build a business that not only generates returns but also provides the resilient energy infrastructure essential for future economic development. While the process is complex, requiring deep technical understanding and meticulous planning, the outcome is a product that can truly stand the test of time and nature.