Entrepreneurs in the solar manufacturing sector often have a well-developed business plan and secured funding, only to face unexpected delays during implementation. The root cause is frequently not technology or the market, but foundational decisions made months earlier—specifically, the choice of the factory site.

In a market like The Gambia, selecting the right piece of land is not merely a real estate transaction; it is a strategic decision that directly impacts operational efficiency, production costs, and long-term viability.

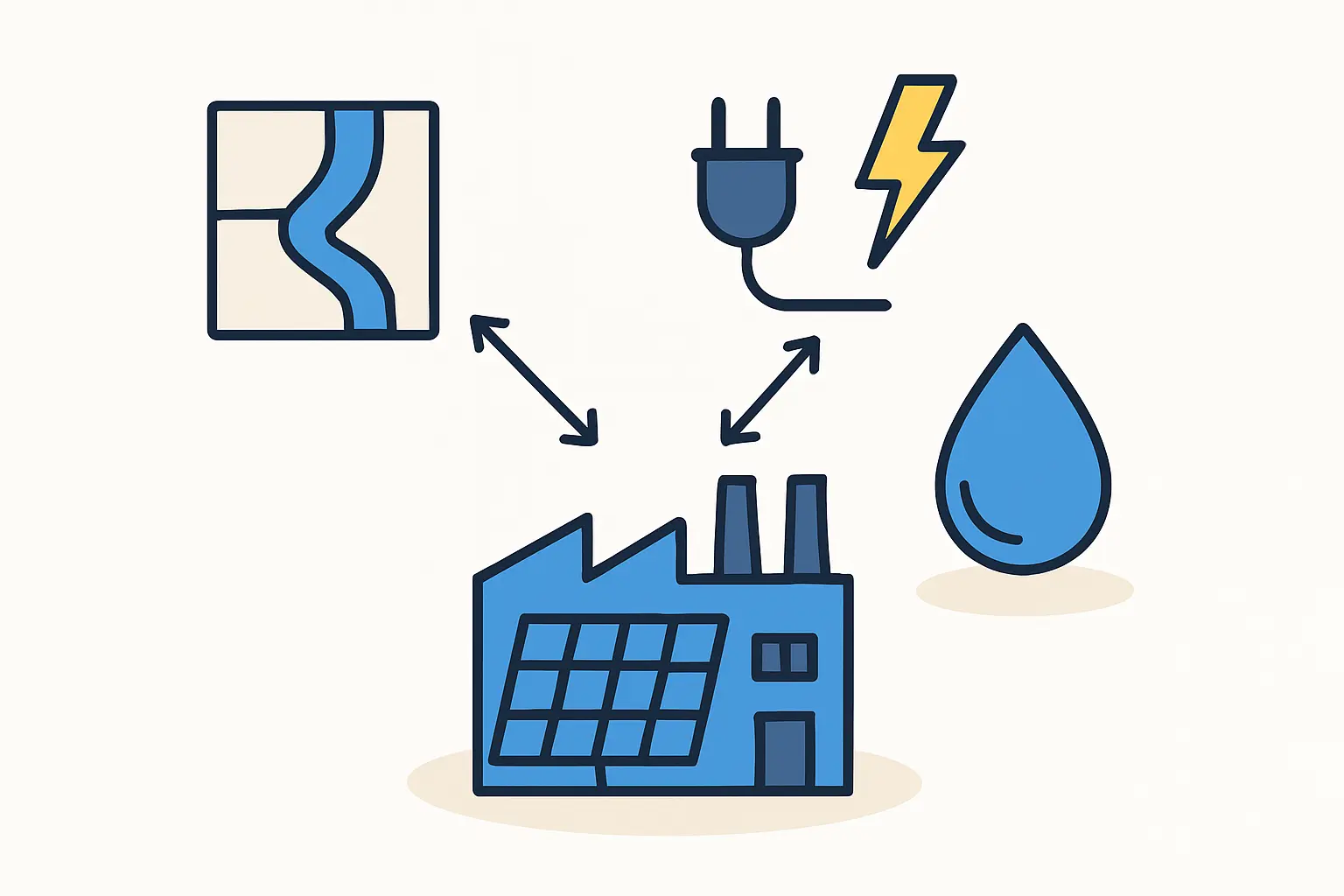

This guide breaks down the critical land and utility considerations for establishing a solar module factory in The Gambia. It focuses on practical challenges and solutions, drawing from on-the-ground realities to help investors make informed decisions from the outset. Understanding these factors is a crucial first step in planning a successful manufacturing venture.

The Strategic Importance of the Greater Banjul Area (GBA)

For any manufacturing business reliant on international supply chains, logistics are paramount. In The Gambia, the economic and logistical heart of the country is the Greater Banjul Area (GBA). Its strategic location and infrastructure make it the logical choice for a solar module factory.

Proximity to the Port of Banjul: A Logistical Necessity

The solar module manufacturing process begins with importing raw materials such as solar cells, glass, aluminum frames, and encapsulants. A factory’s proximity to a major port significantly reduces inland transportation costs and logistical complexities.

The Port of Banjul is the country’s primary maritime gateway. Locating a factory within the GBA ensures that raw materials can be transported from the port to the production facility efficiently and cost-effectively. This proximity also facilitates the future export of finished modules to regional markets within the ECOWAS bloc.

Designated Industrial Zones and Their Advantages

Operating within a designated industrial zone offers substantial advantages over securing a standalone, undeveloped plot of land. These zones are specifically planned for industrial activities and often provide essential infrastructure. In The Gambia, two notable areas are:

- The Julbrew Industrial Estate: Located in the Kanifing Municipality, this is an established industrial hub with existing infrastructure that can support manufacturing operations.

- GIEPA Export Processing Zone (EPZ): Managed by the Gambia Investment and Export Promotion Agency (GIEPA), the EPZ near Banjul International Airport is designed to attract foreign investment. Businesses operating within an EPZ may be eligible for fiscal incentives, such as tax exemptions on imported raw materials and production equipment, which can significantly improve a project’s financial outlook.

Choosing a site within one of these zones can streamline the setup process, as issues like land titles, zoning permits, and basic utility access are often already in place.

Critical Utility 1: Overcoming Power Grid Instability

Perhaps the single most critical operational challenge in The Gambia is the reliability of the national power grid. The National Water and Electricity Company (NAWEC) grid is known for frequent, and often unscheduled, power outages. For a manufacturing facility, this instability is not a minor inconvenience—it is a major business risk.

The NAWEC Grid Challenge and Its Impact on Manufacturing

The Solar Module Manufacturing Process Explained is a sequence of precise, energy-intensive steps. An abrupt power loss can:

- Cause Production Stoppages: Halting a production run midway can lead to wasted materials and significant downtime.

- Damage Sensitive Equipment: Sudden power surges or cuts can damage expensive machinery like laminators and stringers, leading to costly repairs and extended shutdowns.

- Reduce Overall Output: Unpredictable downtime makes it difficult to meet production targets and fulfill client orders, damaging the business’s reputation.

For a serious manufacturing operation, relying solely on the national grid is not a viable strategy. A robust energy backup plan is therefore essential.

Essential Mitigation Strategies for Uninterrupted Power

To ensure continuous operation, a factory must have an independent power solution. The two primary options are:

-

Backup Diesel Generators: This is the most common solution. A generator can switch on automatically during a grid outage, providing uninterrupted power to the production line. It must be sized to handle the full load of the factory’s critical machinery.

-

Solar-plus-Storage System: A more forward-looking and sustainable solution is to install a dedicated solar PV system on the factory roof, coupled with a battery energy storage system (BESS). This system can power the facility during the day, store excess energy, and provide seamless backup during grid failures.

Based on experience from J.v.G. Technology GmbH turnkey projects, a hybrid approach is often most effective. The factory can draw from the grid when it is stable, use its own solar power during the day to reduce electricity bills, and rely on a combination of battery storage and a backup generator to guarantee 100% uptime. This not only secures production but also transforms the factory into a real-world showcase of solar technology’s reliability, enhancing its brand credibility. Planning for this is a key part of determining the overall Investment for a 20-50 MW Solar Factory.

Critical Utility 2: Securing a Reliable Water Supply

While not as water-intensive as other industries, solar module manufacturing requires a consistent supply of clean water, primarily for washing the solar glass before lamination. Any residue, dust, or mineral deposits on the glass can create defects in the final module, leading to lower performance and a higher rejection rate.

Evaluating Water Sources: Public Utility vs. Private Borehole

Like the power supply, the public water network managed by NAWEC can be unreliable. Investors therefore have two main options:

-

Relying on the Public Grid: Connecting to the NAWEC water supply may be sufficient if the local network has a stable track record. However, it is prudent to install large on-site water storage tanks as a buffer against potential service interruptions.

-

Drilling a Private Borehole: For complete water independence, drilling a private borehole is a highly recommended solution. This provides a dedicated, on-demand water source controlled entirely by the factory. While it requires an initial capital investment, it eliminates the risk of public supply disruptions.

The Importance of Water Quality and Treatment

Regardless of the source, water quality is paramount. Groundwater from a borehole or even water from the public supply can contain minerals or impurities. That’s why installing a water purification and deionization system is standard practice, ensuring the water used for cleaning is free of any contaminants that could compromise module quality.

Frequently Asked Questions (FAQ)

What are the main advantages of setting up a factory in a designated industrial zone in The Gambia?

The primary advantages include access to pre-existing infrastructure (roads, power, water), clearer zoning regulations, and proximity to other industrial services. Operating within a GIEPA-managed Export Processing Zone may also provide significant tax incentives and streamlined administrative processes.

Is a backup generator enough, or is a solar-plus-storage system necessary?

A backup generator is the minimum requirement to protect against grid outages. However, a solar-plus-storage system offers additional benefits, including lower long-term energy costs, greater energy independence, and a reduced carbon footprint. For a solar module manufacturer, it also serves as a powerful demonstration of the product’s value. A hybrid system combining both is often the optimal solution.

How much water does a typical small-scale solar module factory consume?

Water consumption is relatively modest and is primarily used for cleaning glass panels. The exact amount depends on the production capacity and specific cleaning equipment used. The key concern is not the volume but the reliability and quality of the supply.

What are the first steps in assessing a potential plot of land?

The first steps involve due diligence to confirm a clear land title and proper zoning for industrial use. A technical assessment should follow, evaluating access to the power grid, potential for water access (including geological surveys for a borehole), and road infrastructure for heavy vehicles. These initial steps are fundamental to establishing a Turnkey Solar Module Production Line.

Laying the Foundation for Success

Choosing the right site in The Gambia is a foundational step that sets the stage for a project’s entire lifecycle. By prioritizing the logistical advantages of the Greater Banjul Area and proactively addressing the critical challenges of power and water instability, an investor can mitigate major operational risks. A site with secure, independent utility solutions provides the stability necessary for a resilient and profitable solar module manufacturing business.