An entrepreneur planning to enter the solar industry in West Africa often focuses on market demand, financing, and logistics. A critical factor that can determine a venture’s long-term success, however, is often overlooked in the initial stages: the specific type of solar module technology best suited for the local climate.

Choosing a technology that fails to withstand the region’s environmental stresses can lead to premature product failures, a damaged brand reputation, and significant financial losses. This article explores why manufacturing a robust module technology like Glass-Glass is a strategic choice for a new facility in Guinea. We will address the unique challenges posed by the country’s high humidity and temperatures, outlining how this technology ensures product longevity and creates a distinct competitive advantage across the West African market.

Understanding Guinea’s Unique Climate Challenge

Guinea’s climate presents two features that are particularly challenging for photovoltaic (PV) technology: intense heat and extreme humidity. Located in a tropical zone, the country experiences a prolonged monsoon season from roughly June to October.

During this period, humidity levels, especially in coastal areas like Conakry, frequently exceed 85%, while average temperatures range between 27°C and 30°C. Inland regions such as Kankan can experience even higher temperatures, often reaching 35°C or more. This combination of persistent moisture and high ambient heat creates a demanding operational environment for any outdoor electronic equipment, especially solar modules that are expected to perform reliably for over 25 years. Understanding these specific environmental pressures is the first step in designing a product that will thrive, not just survive.

The Impact of Heat and Humidity on Standard Solar Modules

While solar modules are designed for durability, not all constructions are equal. The standard and most common type of module, known as Glass-Foil, can be vulnerable to accelerated degradation in tropical climates. This vulnerability stems from two primary failure mechanisms.

The Threat of Moisture Ingress: Delamination and Corrosion

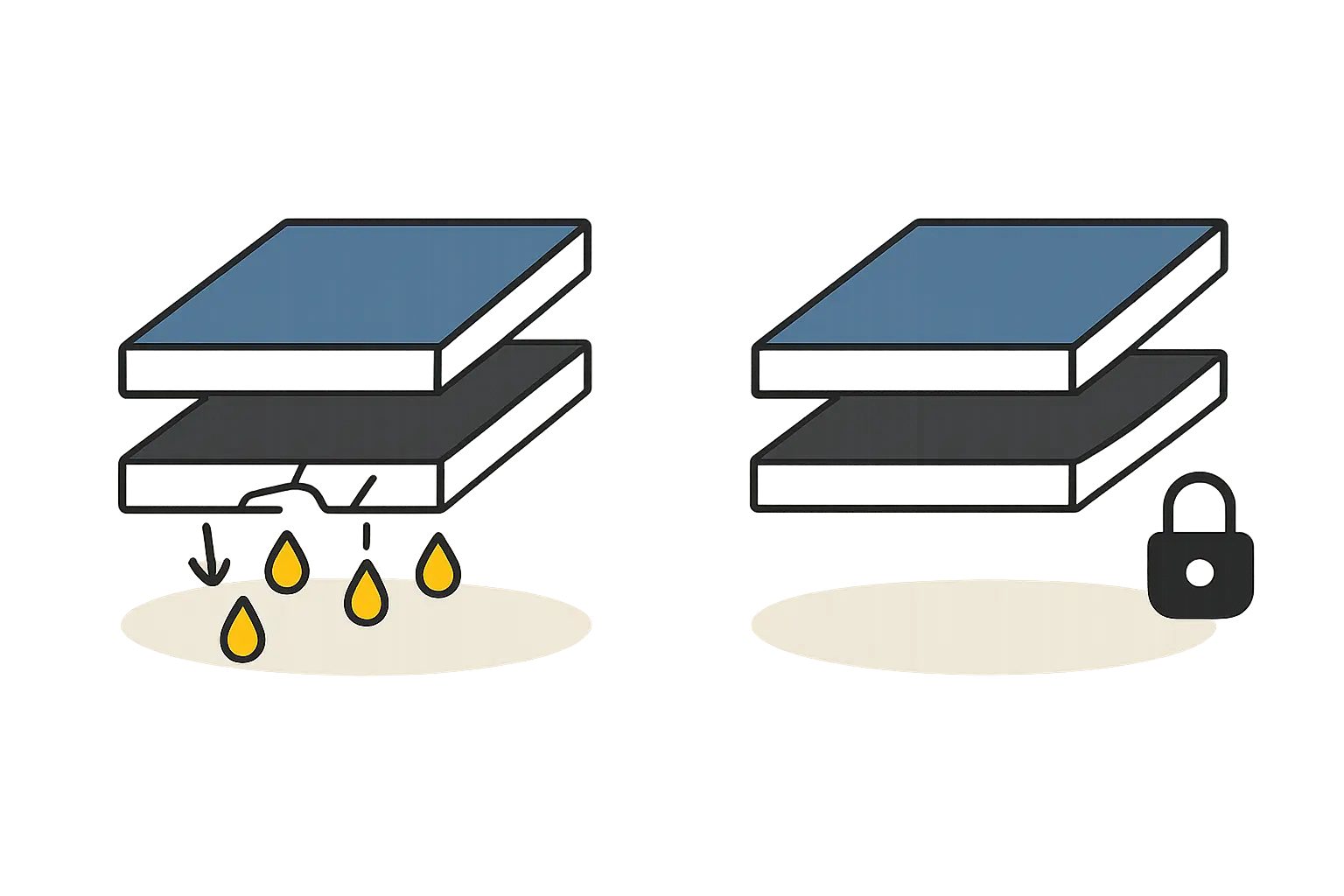

A standard Glass-Foil module consists of a glass front and a polymer-based backsheet. While this backsheet provides electrical insulation and mechanical protection, even high-quality polymers are not completely impermeable to water vapor. Over many years of exposure to high humidity, minuscule amounts of moisture can penetrate the module.

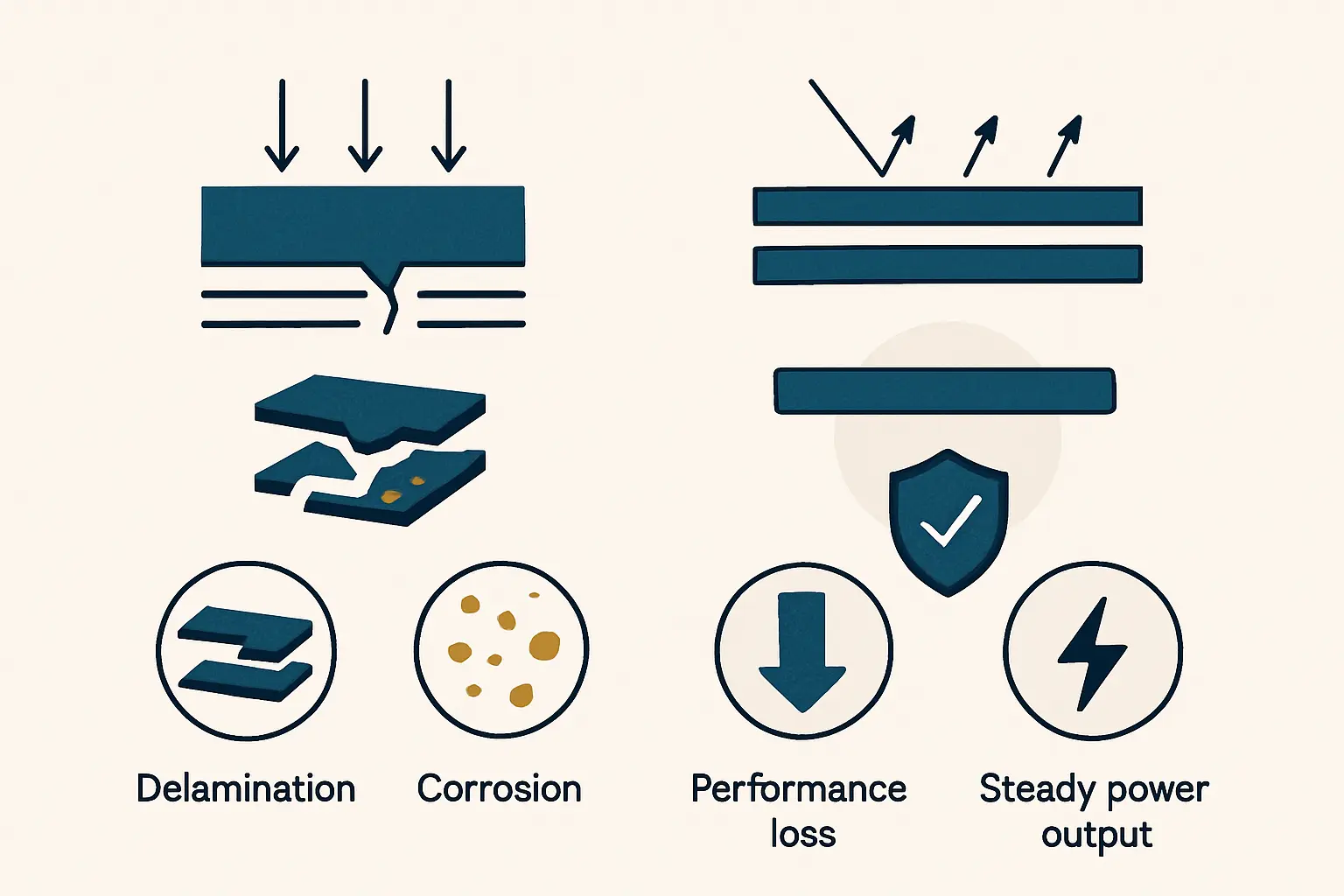

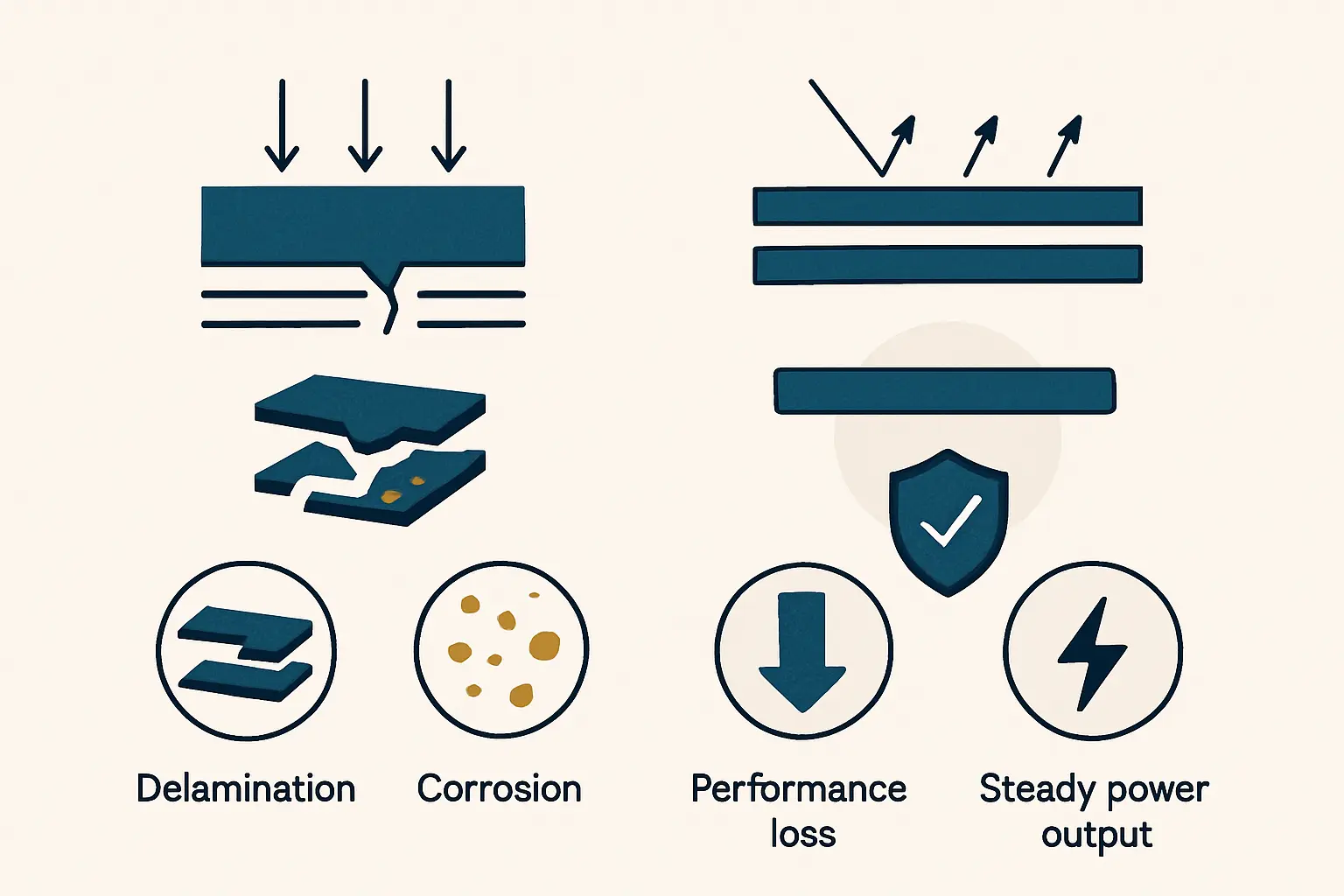

Once inside, this moisture, activated by high temperatures, can cause two critical problems:

-

Delamination: The encapsulant material (typically EVA) that bonds the layers of the module together can lose its adhesive properties. This causes the layers to separate, or ‘delaminate,’ allowing more moisture and air to enter and rapidly accelerating degradation.

-

Corrosion: Moisture can corrode the delicate metallic contacts on the solar cells and the interconnecting ribbons, disrupting the flow of electricity. This process, similar to rust forming on unprotected steel, leads to a permanent loss of power output.

High Temperatures and Performance Loss

High ambient temperatures directly affect a module’s performance and lifespan. For one, all crystalline silicon solar cells produce less power as they get hotter. This predictable drop in efficiency, known as the temperature coefficient, means that on the hottest days, modules are already operating below their peak rated power.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

Sustained heat also accelerates the aging of the materials within the module, particularly the encapsulant and the backsheet. This can lead to issues like the yellowing or browning of the encapsulant, which reduces the amount of light reaching the solar cells. It also makes the polymer backsheet brittle and prone to cracking over time.

A Comparison of Module Technologies: Glass-Foil vs. Glass-Glass

To address these challenges, it’s essential to compare the standard construction with a more robust alternative. The choice of materials for a new solar module manufacturing business is a foundational strategic decision.

Standard Glass-Foil Modules

This conventional design has dominated the industry for decades. It consists of a layer of tempered glass, an encapsulant, the solar cells, another layer of encapsulant, and a polymer backsheet. Its primary advantages have historically been lower weight and cost. However, its main vulnerability remains the polymer backsheet’s susceptibility to moisture ingress and degradation in harsh climates.

The Glass-Glass Advantage

A Glass-Glass module, as its name suggests, replaces the polymer backsheet with a second layer of glass. This simple change in construction creates a ‘sandwich’ of glass that hermetically seals the solar cells from the outside environment.

This design offers several distinct advantages for a climate like Guinea’s. Its superior moisture barrier is a primary benefit, as glass is completely impermeable to water vapor. This effectively eliminates the risk of internal delamination and corrosion caused by humidity.

The symmetric structure provides greater mechanical stability, enhancing durability and making the modules more resistant to stress during transport and installation. Furthermore, Glass-Glass modules inherently offer superior protection against Potential Induced Degradation (PID), an electrical phenomenon exacerbated by heat and humidity. Finally, using glass as the rear layer improves the module’s fire resistance rating, an important factor for rooftop installations.

The Business Case for Manufacturing Glass-Glass Modules in Guinea

Choosing to produce Glass-Glass modules is not merely a technical decision; it is a business strategy that can provide a significant competitive edge.

Building a Reputation for Durability

By manufacturing a product specifically engineered to withstand the regional climate, a new company can immediately differentiate itself from importers of standard modules. Marketing a module as ‘Built for West Africa’ creates a powerful message of quality and reliability. This is especially important for government tenders and commercial projects where long-term performance is a non-negotiable requirement.

Securing a Long-Term Market Advantage

As the solar market in West Africa matures, customers will become more discerning. Those whose initial installations of lower-quality modules fail prematurely will seek out more reliable alternatives. A manufacturer with a proven track record of producing durable, climate-appropriate modules will be well-positioned to capture this growing demand. Experience from J.v.G. turnkey projects shows that new manufacturers who focus on application-specific quality from the start build more sustainable businesses.

Aligning with Global Technology Trends

The global solar industry is increasingly moving towards advanced concepts like bifacial technology, which captures light from both sides and is almost exclusively built on a Glass-Glass platform. By investing in the capability to produce Glass-Glass modules from day one, a factory in Guinea not only solves a current problem but also prepares for the next wave of solar technology. Setting up flexible turnkey solar production lines that can handle both technologies offers maximum future-proofing.

Frequently Asked Questions (FAQ)

Is Glass-Glass technology much more expensive to produce?

While there was historically a significant cost difference, technological advancements and economies of scale have narrowed the price gap considerably. The additional upfront cost for materials is often minimal compared to the long-term value created through enhanced reliability, a longer lifespan, and the stronger bankability of projects using these modules.

Are the machines different for Glass-Glass production?

The core manufacturing process is very similar to Glass-Foil production. Key machines, like the laminator, must be capable of handling the symmetric Glass-Glass structure, but this is a standard feature on most modern equipment. The planning phase of a new factory should account for this requirement.

Does this technology require special certification?

All solar modules must pass standard safety and performance tests, such as IEC 61215 and IEC 61730, to be sold on the international market. Glass-Glass modules typically perform exceptionally well in these tests, especially in extended reliability sequences like damp-heat tests. Passing these rigorous tests is a key part of the module certification process and serves as a powerful marketing tool.

Conclusion: Making a Strategic Technology Choice

For an entrepreneur establishing a solar module factory in Guinea, the choice of technology should be guided by the local environment. While standard Glass-Foil modules may be adequate for more temperate climates, the combination of high heat and relentless humidity in West Africa calls for a more robust solution.

Choosing Glass-Glass module production is a strategic decision that directly mitigates the primary risk of premature failure. It lays the foundation for a brand built on quality, durability, and a deep understanding of the regional market’s needs—creating a sustainable and competitive advantage for years to come.