While the global demand for standard solar modules continues to grow, a highly specialized and potentially more profitable niche is rapidly expanding within France: agrivoltaics, or Agri-PV.

For entrepreneurs considering the solar manufacturing sector, understanding the needs of such specific markets offers a significant competitive advantage over producing mass-market commodities. This article explores the unique opportunity in French agrivoltaics, outlining the market drivers, the demanding technical requirements for these specialized modules, and the business case for focusing a manufacturing operation on this high-value segment.

What is Agrivoltaics and Why is France a Key Market?

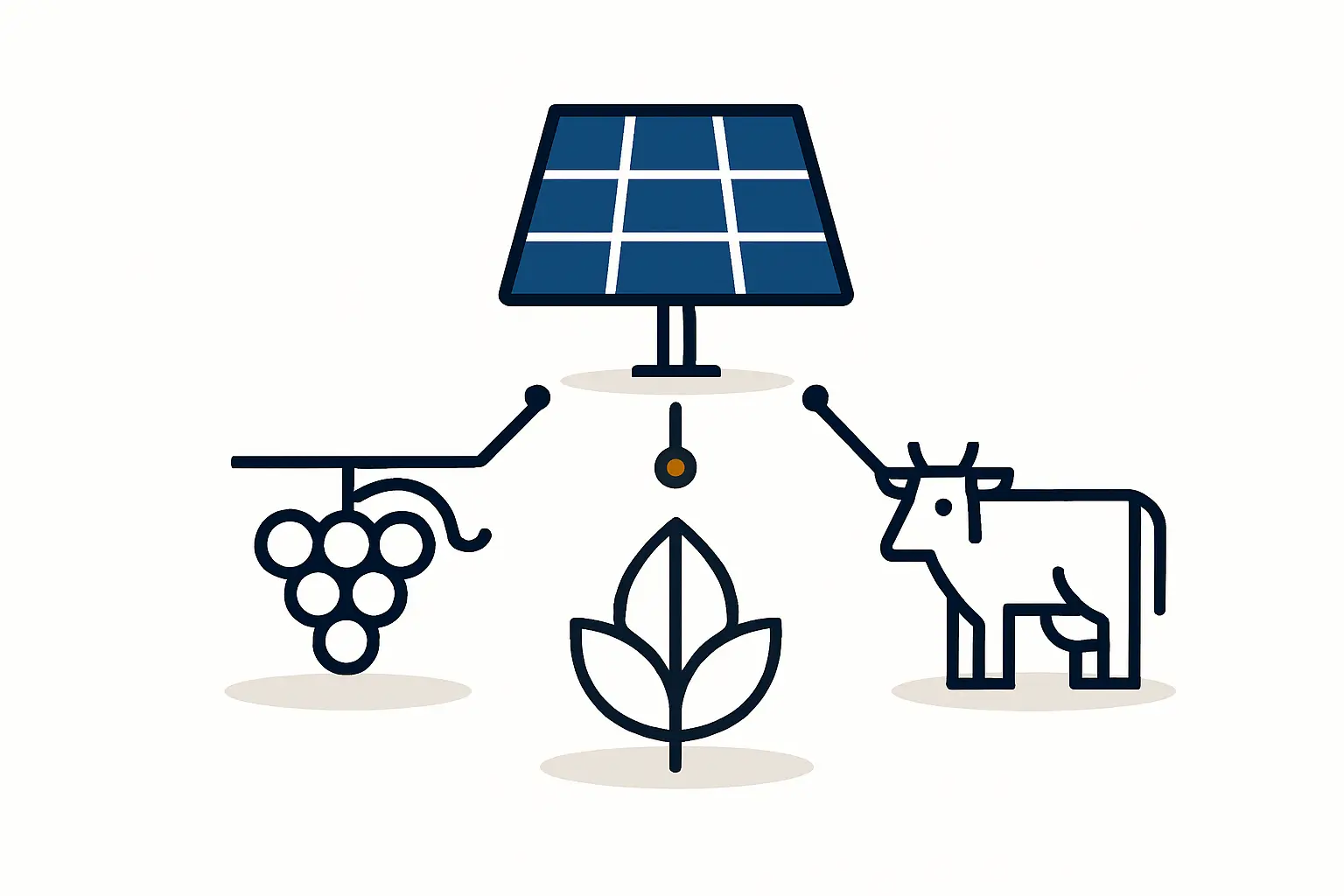

Agrivoltaics combines solar power generation and agriculture on the same land. Instead of covering fields entirely, solar modules are mounted on tall structures, allowing farming activities like crop cultivation or animal grazing to continue underneath.

This dual-use approach addresses land-use conflicts and creates symbiotic benefits: crops can be protected from excessive sun or hail, while the modules generate clean energy. France has emerged as a European leader in this field, driven by strong government support and a proactive agricultural sector.

Market Growth and Government Incentives

The French market for Agri-PV is poised for substantial growth. From just 40 MW of installed capacity in 2021, the market is projected to expand to 2 GW by 2030. This growth is underpinned by government tenders specifically designed for agrivoltaic projects.

These tenders often include stringent requirements, such as a low carbon footprint for the modules, which favors European-based manufacturing. The result is a protected market segment where manufacturers who can meet specific technical and environmental criteria face less competition from high-volume, standard module producers.

Unique Technical Demands of Agri-PV Modules

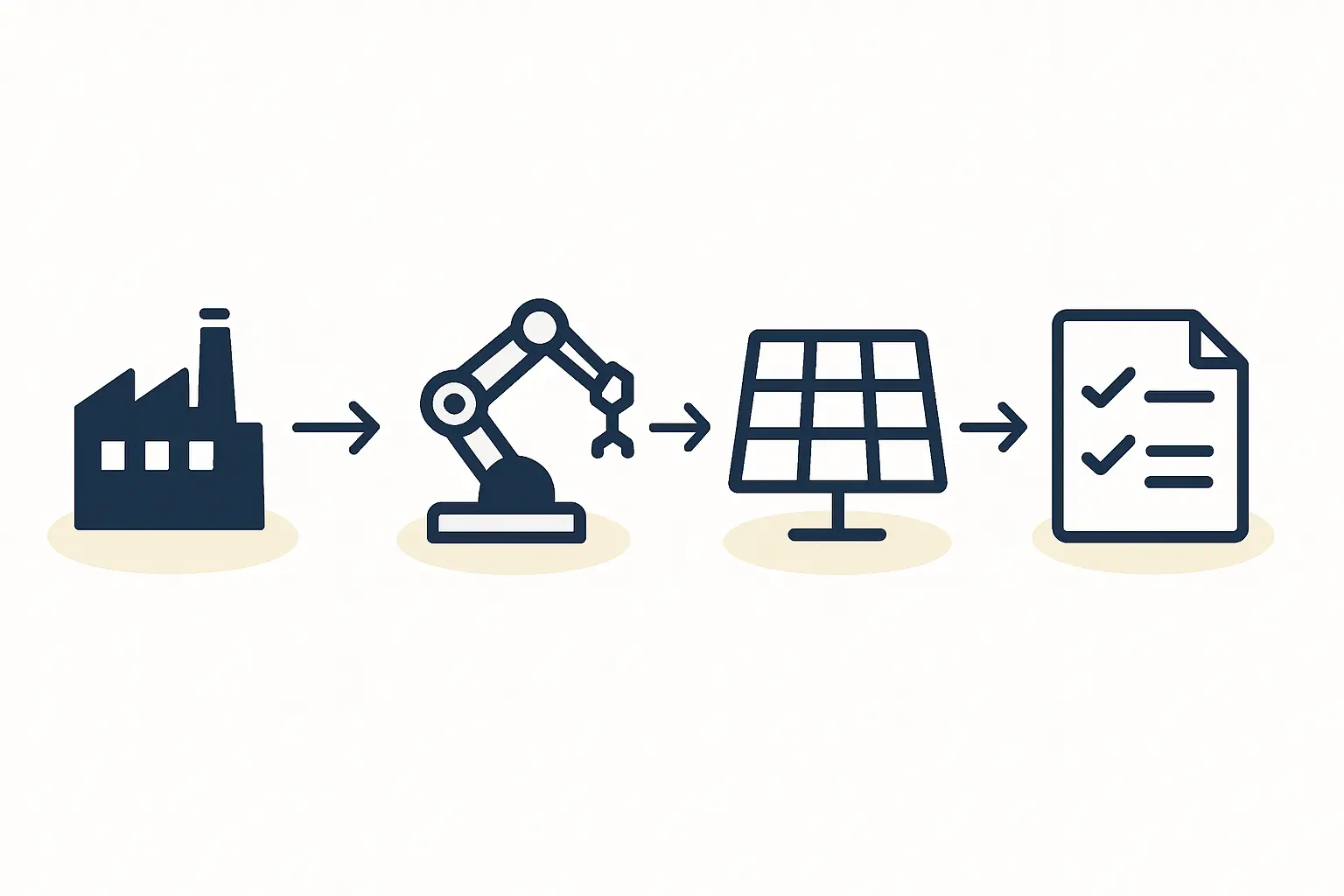

Manufacturing solar modules for agrivoltaic applications is fundamentally different from standard production. The modules are not just energy generators; they are an integral part of an agricultural ecosystem. This reality demands a shift in design philosophy and material selection, requiring manufacturers to first understand the complete solar module manufacturing process and then adapt it to these specific needs.

1. Optimized Light Transmittance

Unlike standard modules designed for maximum opacity and power output, Agri-PV modules must be semi-transparent to let enough sunlight pass through to support the crops below.

- Specification: Modules typically require a light transmittance of 30% to 50%, depending on the type of crop being cultivated.

- Manufacturing Implication: This is achieved by adjusting the spacing between solar cells during the stringing and layout process, a step that demands precise machinery and quality control to ensure uniform transparency across the module.

2. Enhanced Durability and Resistance

An agricultural environment is far harsher than a typical rooftop or solar farm, so modules must withstand unique physical and chemical stresses.

- Ammonia Resistance: Livestock farming releases ammonia, which is highly corrosive to components like backsheets and junction boxes. Modules must be certified to IEC 62716 to guarantee their long-term performance in these environments.

- Mechanical Stress: Modules must be robust enough to resist impacts from small farm machinery, falling tools, or other operational hazards. This often involves using thicker, more durable glass on both the front and back.

- Hail Resistance: Given their role in crop protection, Agri-PV modules must withstand severe weather. Certification to IEC 61215 for hail impact—often using larger ice balls in testing than the standard requires—is a key selling point.

3. Bifacial Cell Technology

To maximize energy yield, most Agri-PV designs use bifacial solar cells. A bifacial solar module can capture direct sunlight on its front side as well as light reflected from the ground and crops onto its rear side.

- Benefit: This can increase total energy production by 5–15%, improving a project’s financial viability.

- Manufacturing Implication: Production requires a transparent backsheet or, more commonly, a dual-glass (glass-glass) construction, which adds weight and requires different handling during lamination and framing.

4. Custom Sizes and Formats

Agri-PV installations are rarely standardized. The size and shape of the modules often need to be customized to fit a specific support structure and crop layout. A manufacturer must have the flexibility to produce non-standard dimensions, which can be a challenge for highly automated, large-scale production lines designed for uniformity.

The Business Case for Specialization

Entering the solar manufacturing market with standard modules means competing directly on price with established, billion-dollar companies. Focusing on a niche like French agrivoltaics offers a different path.

- Higher Profit Margins: Specialized modules command higher prices due to their complex design, superior materials, and performance guarantees. Their value lies not just in the watts produced but in the module’s dual function.

- Lower Competition: The high technical barrier to entry filters out many mass-market producers.

- Strong Market Pull: With dedicated government tenders, demand is clear and consistent, reducing market risk for new entrants who can meet the specifications.

Based on experience from J.v.G. turnkey projects, the primary challenge is not a lack of demand, but establishing a production facility that can consistently meet these stringent quality standards.

Key Considerations for a Production Line Setup

Setting up a factory to produce Agri-PV modules requires careful planning. While the core processes resemble standard module manufacturing, several areas need special attention.

- Specialized Equipment: A standard laminator may not accommodate thicker glass-glass construction or custom module sizes. The stringer machine must be programmable for variable cell spacing.

- Quality Control: Rigorous testing is essential to ensure compliance with certifications like IEC 62716 (ammonia) and advanced hail tests. This requires investing in specialized testing equipment.

- Supply Chain: Sourcing materials like thicker glass, ammonia-resistant junction boxes, and appropriate encapsulants is critical and demands relationships with specialized suppliers.

For entrepreneurs new to the industry, structuring this complex project is paramount. A well-designed turnkey solar module manufacturing line can be configured from the outset to handle the flexibility required for Agri-PV production.

Frequently Asked Questions (FAQ)

Are Agri-PV modules significantly more expensive to produce?

Yes, the upfront material and production costs are higher due to the use of bifacial cells, dual-glass construction, and more robust components. However, this higher cost is offset by the higher selling price and profit margins these specialized modules command.

What is the most challenging part of manufacturing Agri-PV modules?

The greatest challenge is ensuring consistent quality and durability. Meeting the specific certifications for ammonia resistance and mechanical load requires meticulous process control and material selection. Additionally, managing the logistics of producing custom, non-standard module sizes can be complex.

Can a standard solar factory be adapted to produce Agri-PV modules?

It is possible, but this often requires significant investment in new or modified equipment. Key machines like the laminator, cell stringer, and framing station may need to be upgraded or replaced to handle different materials and module formats. It is generally more efficient to design the factory for this purpose from the beginning.

How important is a low carbon footprint for the French market?

It is extremely important. French government tenders for renewable energy projects, particularly in agrivoltaics, use a carbon footprint evaluation (Évaluation Carbone Simplifiée – ECS) as a key criterion. Modules manufactured in Europe with a transparent, low-carbon supply chain have a distinct advantage over imports from Asia.

Next Steps for Consideration

The French agrivoltaics market represents a compelling opportunity for manufacturers who prioritize specialization over scale. It is a market where technical excellence, durability, and customization are valued more than the lowest cost per watt.

For business professionals exploring this sector, a deeper analysis of the financial and technical requirements is the logical next step. Turning this market opportunity into an operational reality requires developing a comprehensive business plan, understanding equipment specifications, and mapping out the supply chain.