At first glance, establishing a solar panel manufacturing facility in Iceland seems paradoxical. Why build a factory for sun-powered technology in a subarctic nation known for its long, dark winters?

For the discerning entrepreneur, the answer lies not in the local weather but in Iceland’s unique industrial advantages: abundant, low-cost geothermal and hydroelectric energy, a highly skilled workforce, and a strategic location between Europe and North America.

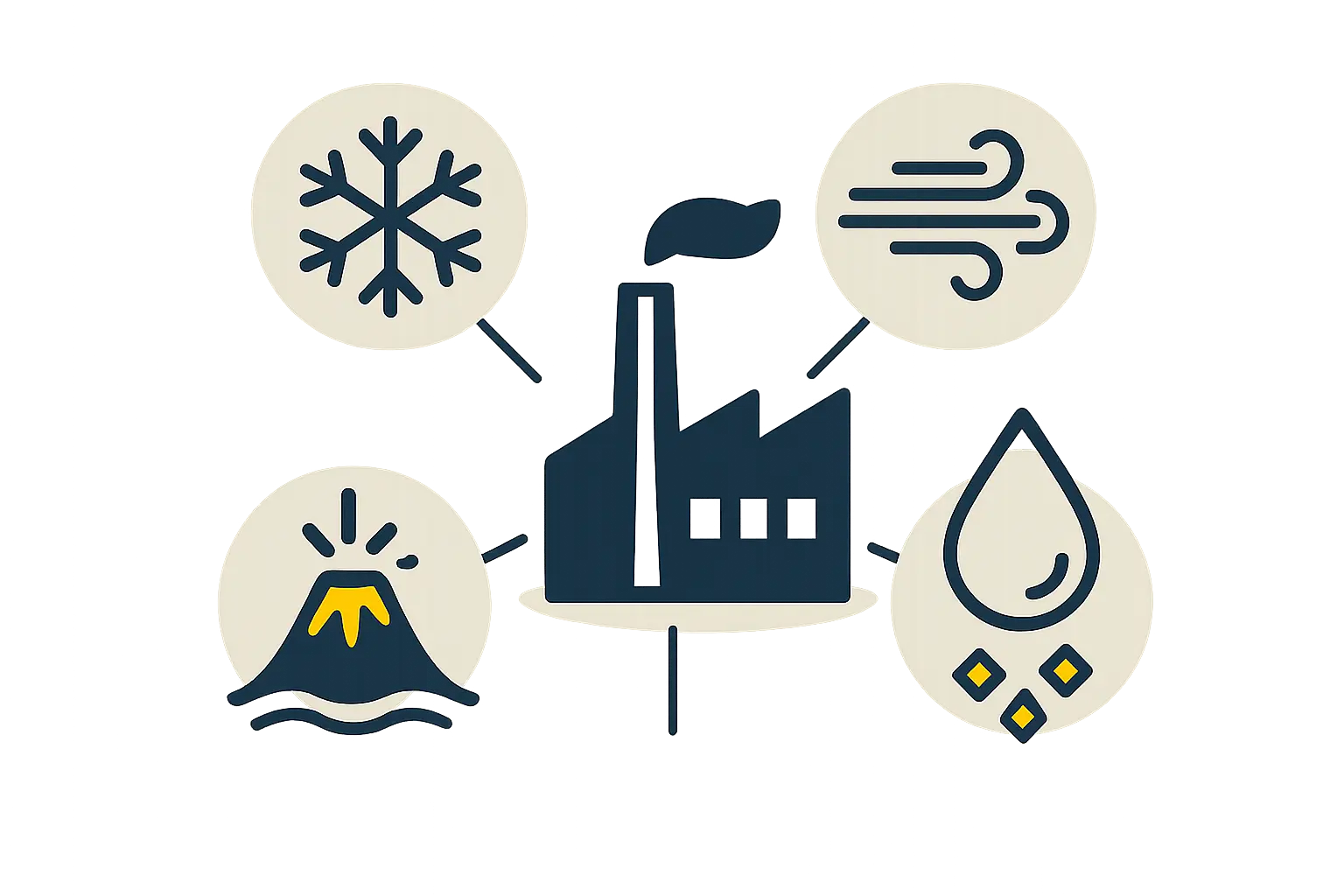

Harnessing these benefits requires a specialized approach to factory construction, as a standard European design simply won’t suffice. Iceland’s environment—with its high winds, heavy snow loads, and seismic activity—demands a purpose-built facility engineered for resilience and efficiency. This guide outlines the critical infrastructure and construction considerations for investors looking to capitalize on this unique manufacturing opportunity.

Site Selection: Beyond the Cost of Land

Choosing the right location in Iceland is a strategic decision that directly impacts both capital expenditure and long-term operational costs. While land may be available, the optimal site must balance geological stability with access to infrastructure.

Proximity to Geothermal and Grid Infrastructure

Iceland’s primary competitive advantage is its access to some of the world’s cheapest and most reliable green energy. A solar module factory is energy-intensive, with processes like lamination and cell testing consuming significant power.

Based on J.v.G.’s experience with turnkey projects, a 50 MW production line consumes over 1.5 million kWh of electricity annually. Locating the factory near a geothermal power plant or a major substation reduces energy transmission costs and ensures a stable supply, directly lowering the per-module production cost. Areas like the Reykjanes Peninsula or the vicinity of the Hellisheiði Power Station are prime examples of locations offering this advantage.

Logistics and Port Access

Virtually all raw materials for solar module manufacturing—from solar cells and glass to aluminum frames—will be imported. The factory must have efficient access to a major port, such as Reykjavík or Hafnarfjörður, to manage inbound supply chains and outbound product distribution. A location within a 50-kilometer radius of a port is generally considered optimal to minimize transportation costs and potential delays.

Structural Engineering: Designing for the Elements

The building itself is the first line of defense against Iceland’s demanding climate. Its structural design must go far beyond standard industrial building codes to ensure personnel safety, the protection of high-value machinery, and uninterrupted operations.

Wind and Snow Load Capacity

Icelandic building regulations (Byggingarreglugerð) are rigorous, particularly concerning climatic loads. A factory building must be engineered to withstand:

-

Extreme Wind Forces: Coastal areas can experience wind speeds exceeding 180 km/h. The building’s steel frame, cladding, and roofing must be specified to handle these dynamic forces without failure.

-

Heavy Snow Accumulation: Depending on the region, roof structures must support significant snow loads, often exceeding 3.0 kilonewtons per square meter (kN/m²). A pitched roof design is often favored over a flat roof to facilitate snow shedding.

Failing to account for these factors can lead to catastrophic structural damage and production halts, turning a seemingly small cost-saving measure into a significant liability.

Seismic Considerations

Iceland is geologically active. While building codes incorporate seismic resilience, a manufacturing facility housing sensitive equipment requires enhanced structural integrity. This includes reinforced concrete foundations and flexible steel superstructures designed to absorb ground motion. Selecting a site with low historical seismic activity is a primary risk mitigation step. Entrepreneurs considering this venture should review the investment requirements for a solar factory to understand how these structural enhancements factor into the overall budget.

Building Envelope and Climate Control: The Key to Efficiency

The performance of the building’s “envelope”—its walls, roof, and flooring—is critical to maintaining the stable internal environment needed for high-quality solar module production.

Superior Insulation Standards

High-performance insulation is not an option; it is a necessity to combat the extreme temperature difference between the factory’s interior (typically 20–25°C) and the outside.

Wall and Roof Panels: Insulated metal panels (IMPs) with a thick polyurethane or mineral wool core are standard. A U-value (a measure of heat loss) of 0.15 W/m²K or lower is recommended for the Icelandic climate, significantly exceeding typical European industrial standards.

Foundation Insulation: Insulating the concrete slab foundation is essential to prevent heat loss to the ground and to avoid issues with frost heave, which can damage the building structure and misalign sensitive machinery like solar cell stringers.

HVAC and Dehumidification Systems

Solar module manufacturing involves processes that are highly sensitive to humidity and airborne particulates. The lamination process, where the module’s layers are fused together, requires a strictly controlled environment.

-

Positive Pressure Environment: The production hall should be maintained under positive air pressure to prevent dust and contaminants from entering.

-

Humidity Control: A robust HVAC (Heating, Ventilation, and Air Conditioning) system with integrated dehumidification is essential to maintain relative humidity below the thresholds specified for EVA or POE encapsulant films. High humidity can compromise module adhesion and lead to long-term delamination issues.

Investing in a superior building envelope and climate control system directly translates to lower energy bills and higher product quality—a crucial factor for achieving bankability and international certification.

Frequently Asked Questions (FAQ)

What is the typical floor space required for a small-to-medium solar factory in Iceland?

A production line with an annual capacity of 20–50 MW typically requires a building with a total floor space of 2,500 to 5,000 square meters. This includes space for raw material storage, the main production hall, finished goods warehousing, and administrative offices. Ceiling height in the production area should be at least 6 meters to accommodate machinery and material handling equipment.

How does the lack of winter daylight affect construction and operations?

The construction timeline needs to account for limited daylight hours and potentially severe weather during the winter months. A project plan should schedule most of the external structural work for the summer. Once the building is enclosed, interior work can proceed year-round. For operations, the factory relies on artificial lighting, and the 24/7 availability of low-cost electricity in Iceland makes this economically viable.

Are there specific challenges with importing manufacturing equipment to Iceland?

Logistics are straightforward via major shipping lines, but working with a freight forwarder experienced in handling oversized and delicate industrial machinery is critical. All equipment must be properly crated and protected for sea transport. The process of selecting solar manufacturing machines should include considerations for transport and installation logistics from the outset.

Does the Icelandic government offer incentives for this type of investment?

Yes, Invest in Iceland, the national investment promotion agency, provides information and assistance for foreign investors. Incentives can include reduced corporate taxes, training grants, and support with navigating regulatory processes. Entrepreneurs should engage with this agency early in the planning phase.

Planning for a Resilient and Profitable Future

Building a solar panel factory in Iceland presents a formidable set of environmental challenges. Yet with meticulous planning, specialized engineering, and a focus on resilience, these can be transformed into a strategic advantage. By leveraging the nation’s unparalleled access to green energy, a well-built Icelandic factory can produce solar modules with one of the lowest carbon footprints in the world at a highly competitive cost.

The key is to recognize that the factory building is not merely a structure but an integral part of the manufacturing equipment itself. For investors new to the solar industry, understanding these specific construction requirements is the first step toward developing a robust and realistic business plan.