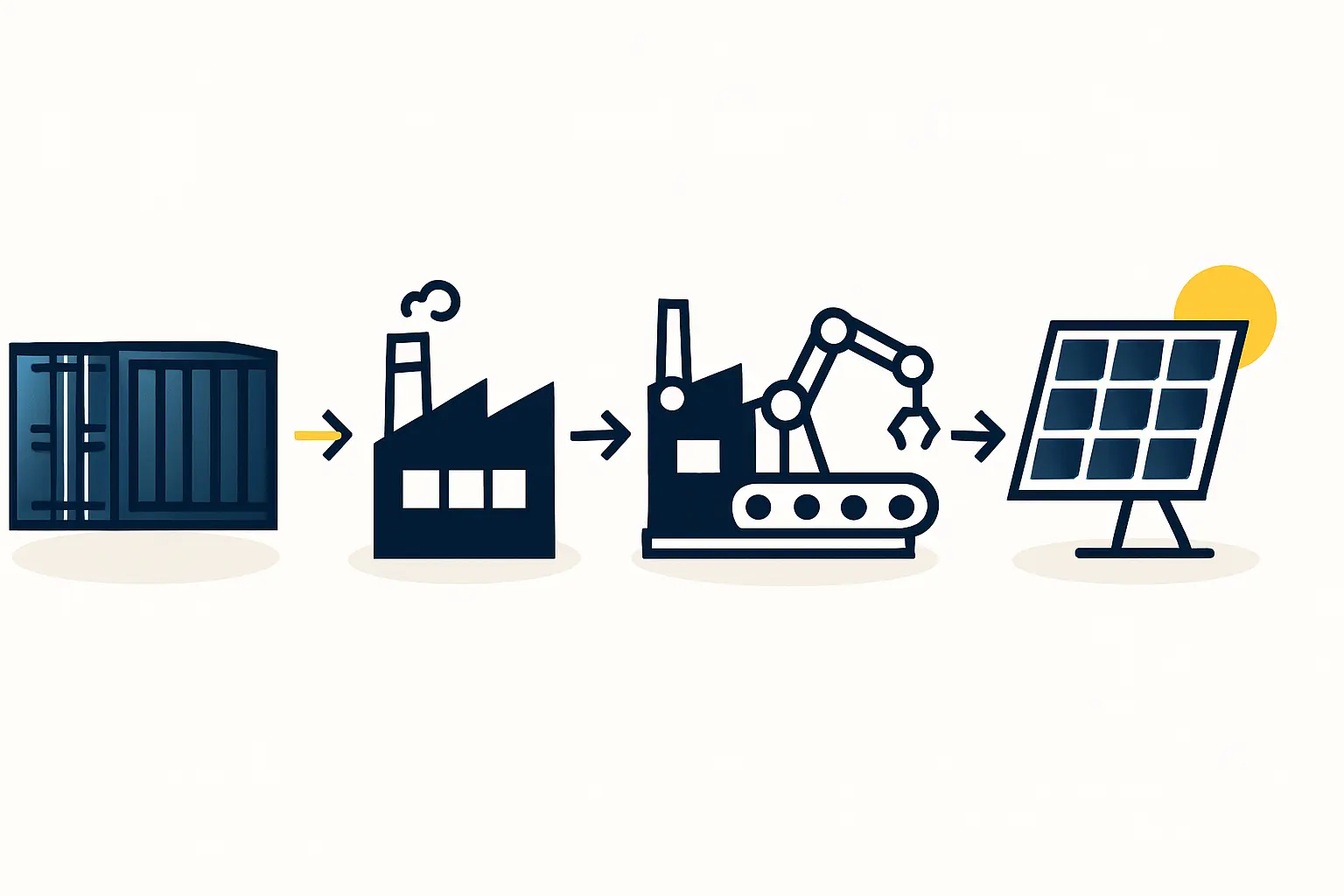

For an entrepreneur considering entry into the solar industry, the supply chain is one of the most critical considerations. After selecting a country for a new solar module factory, the immediate challenge is to secure a reliable and cost-effective supply of raw materials. The decision to source locally versus import components has a profound impact on cost structure, logistics, and operational resilience. This choice is foundational when starting a solar panel manufacturing business, as it directly affects the venture’s viability from day one.

Hungary, with its strategic location and robust industrial base, is a compelling option. However, a potential investor must look beyond these macro-level advantages and carefully analyze the domestic supply chain. This article objectively assesses Hungary’s capacity to supply the key raw materials for solar panel manufacturing, exploring both the opportunities and the realities of local sourcing.

The Strategic Advantage of Hungary’s Central European Location

Hungary’s geographical position is one of its primary assets. Situated at the crossroads of Europe, it offers excellent logistical connections to established Western European markets and the rapidly growing renewable energy sectors in Central and Eastern Europe. This central location is a significant factor when choosing the right factory location, as it can substantially reduce transportation costs and delivery times for incoming raw materials and outgoing finished modules.

This logistical advantage means that even when certain high-tech components are not produced domestically, they can be sourced efficiently from neighboring industrial powerhouses like Germany, Austria, or Poland. A factory in Hungary, therefore, is not an isolated island but a well-connected hub in a broader European manufacturing ecosystem.

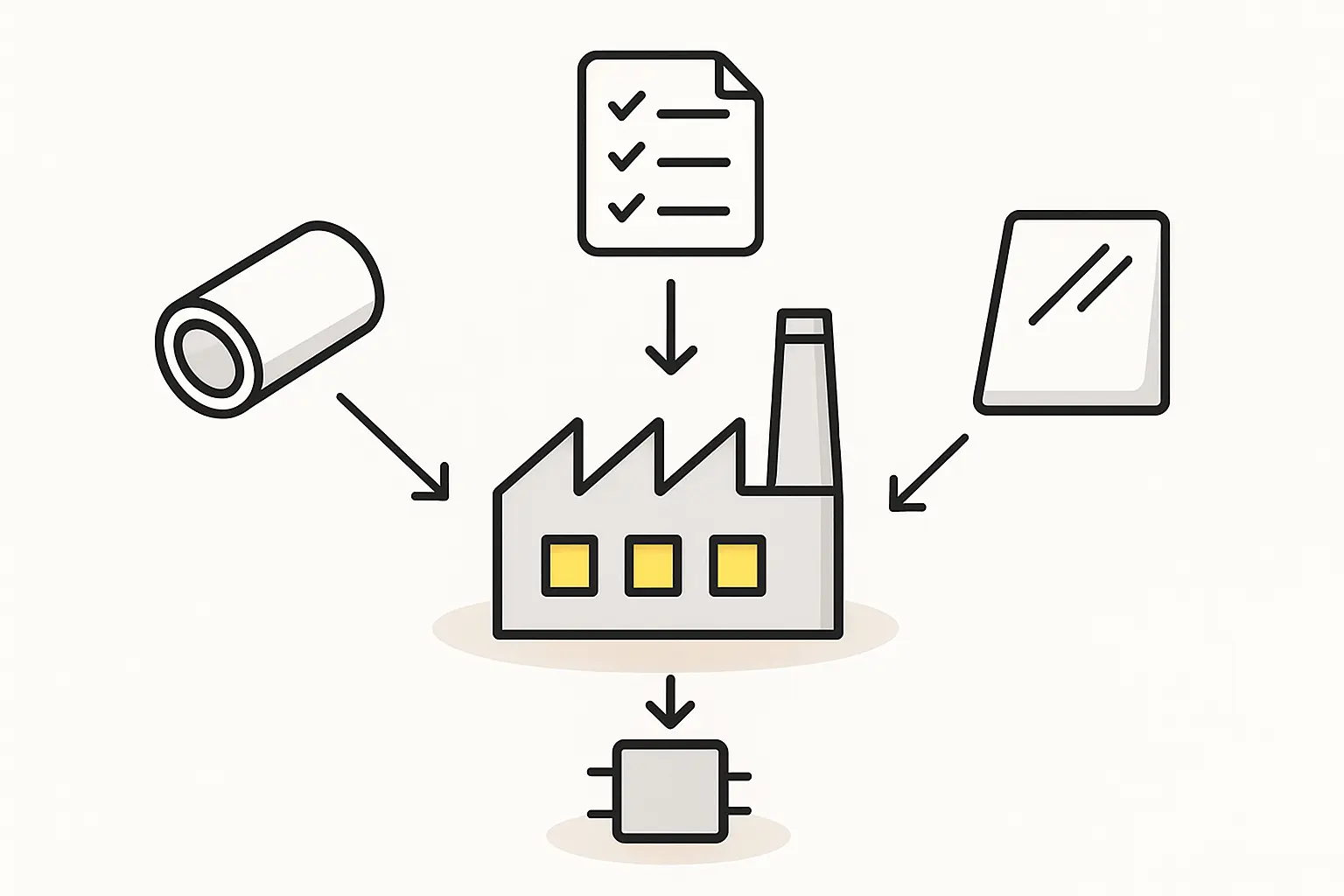

A Component-by-Component Analysis of Local Sourcing

A standard photovoltaic (PV) module is assembled from several critical components. A successful sourcing strategy depends on understanding which of these key raw materials for solar panels can be procured locally and which may need to be imported regionally or globally.

Aluminum Frames: Leveraging the Automotive Industry

One of Hungary’s greatest industrial strengths lies in its advanced automotive manufacturing sector. This offers a direct and powerful synergy for a new solar module factory. The same suppliers that produce high-precision, high-volume extruded aluminum profiles for major car brands have the technical capabilities and quality control systems (such as ISO 9001) required for manufacturing solar panel frames.

Key advantages include:

- Established Expertise: Local suppliers are already proficient in aluminum extrusion and anodization.

- Reduced Logistics: Sourcing frames domestically eliminates long sea voyages, cutting both costs and the risk of transport damage.

- Lower Working Capital: Shorter lead times mean less capital is tied up in inventory.

Based on experience from J.v.G. turnkey projects in similar industrial regions, leveraging local suppliers for bulky components like frames can significantly reduce initial procurement costs and lead times compared to importing from distant markets.

Solar Glass: A Likely Import Requirement

Solar glass is not ordinary glass. This highly specialized product—typically low-iron, tempered glass with an anti-reflective coating—is designed to maximize light transmission. While Hungary has a glass industry, the production of this specific solar-grade glass is dominated by a few large global players.

Therefore, investors should realistically expect to import solar glass. However, thanks to Hungary’s location, sourcing from major European producers in Germany, France, or Poland is logistically straightforward and often more reliable than sourcing from other continents.

Junction Boxes and Backsheets: Opportunities in Polymers

The manufacturing of junction boxes, which house a module’s electrical components, relies heavily on high-quality injection-molded plastics. Much like with aluminum frames, Hungary’s automotive and electronics industries have cultivated a strong domestic ecosystem of companies specializing in polymer processing. Sourcing junction box housings locally is often a feasible and cost-effective option.

Backsheets, the protective polymer layers on the rear of a panel, are more specialized. While the base materials may be available, the complete, multi-layered product is typically procured from specialized international suppliers.

Solar Cells and Wafers: The International Influence

The heart of a solar module is the solar cell. The production of silicon wafers and cells is the most capital-intensive and technologically complex part of the value chain, a segment historically dominated by Asian manufacturers.

However, a significant trend is emerging: major international solar companies are establishing large-scale production facilities in Hungary. This means that while the technology and ownership may be foreign, the physical production of cells is becoming increasingly localized. For a new module assembler, this creates a major opportunity to source the most critical component from a supplier within the country, drastically simplifying logistics and strengthening the supply chain.

Balancing Cost, Quality, and Logistics

The optimal sourcing strategy for a solar factory in Hungary is a hybrid model that leverages domestic strengths while realistically planning for necessary imports.

-

High Local Availability:

- Aluminum Frames (from automotive suppliers)

- Junction Box Casings (from plastics industry)

- Packaging Materials

-

Regional Sourcing (Europe):

- Solar-Grade Glass

- Encapsulants (EVA/POE)

- Backsheets

-

Globally-Sourced (but with growing local production):

- Solar Cells

- Interconnector Ribbon

This balanced approach allows a manufacturer to optimize for cost, ensure high quality by using specialized suppliers, and build a resilient supply chain that is not overly dependent on a single country or region.

Frequently Asked Questions (FAQ)

What is the biggest advantage of sourcing locally in Hungary?

The primary advantage is the ability to tap into the country’s high-quality industrial ecosystem, especially its automotive sector. This gives manufacturers immediate access to experienced suppliers for structural and plastic components like frames and junction boxes, which can reduce logistics costs and improve supply chain reliability.

Are Hungarian suppliers ready for the quality demands of the solar industry?

Many suppliers, particularly those serving the German automotive industry, already operate under stringent quality management systems like ISO 9001. While they may need guidance to meet specific solar certifications (e.g., IEC standards), their underlying quality is typically very high. Working in partnership with these suppliers is an effective way to bridge any specific knowledge gaps.

Does sourcing locally make a solar factory more profitable?

It can significantly improve profitability by reducing the working capital tied up in shipping and inventory. It also lowers exposure to international shipping volatility and currency fluctuations. While the per-unit price of a component from a global mass producer might sometimes be lower, the total landed cost and associated risks of importing are often higher.

What about other materials like encapsulants (EVA) or ribbon?

These are highly specialized chemical and metal products, typically sourced from major global chemical and metallurgical companies with a presence in Europe. A factory in Hungary can access these materials through European distribution channels, ensuring quality and a relatively stable supply.

Conclusion: A Viable and Growing Ecosystem for Module Assembly

Hungary is a strong and strategically sound location for solar module assembly. The country’s industrial foundation, particularly in automotive manufacturing, provides a ready-made supply chain for critical structural components. This domestic strength, combined with the growing local presence of international cell manufacturers and excellent logistical links to European suppliers of specialized materials, creates a robust and viable ecosystem.

For an investor, the key to success is not to seek 100% local sourcing but to develop an intelligent, hybrid strategy. This involves capitalizing on domestic advantages for certain parts while building reliable import channels for others. Crafting such a sourcing plan is a core part of the business planning process, requiring careful evaluation and expert guidance.