Entrepreneurs venturing into solar module manufacturing often focus first on machinery and capital investment. While critical, these elements are only part of the equation. An often-overlooked factor crucial for long-term success is the availability and skill level of the local workforce.

Iran, with its strong academic tradition in engineering, presents a unique landscape of both opportunity and specific challenges for new factory owners.

The question, then, is not whether talent exists, but how to transform a large pool of academically qualified individuals into a high-performing, factory-ready technical team. This requires a strategic approach to recruitment, training, and workforce development.

The Untapped Potential of Iran’s Technical Workforce

On the surface, Iran appears well-positioned to support a growing manufacturing sector. The country produces a high volume of university graduates each year, with many specializing in engineering disciplines relevant to solar manufacturing.

-

High Volume of Graduates: Iranian universities consistently graduate tens of thousands of engineers in fields such as electrical, mechanical, material science, and chemical engineering. This creates a large recruitment pool with a solid theoretical foundation.

-

Strong Analytical Skills: The curriculum in these programs typically emphasizes rigorous scientific and mathematical principles, fostering strong problem-solving and analytical capabilities.

-

Established Industrial Base: Decades of activity in sectors like automotive, petrochemicals, and electronics manufacturing have created a generation of technicians and engineers familiar with industrial processes, quality control, and production line discipline.

This existing human capital is a major asset for any new enterprise. However, converting this raw potential into specialized operational excellence is the first major hurdle.

The Crucial Gap: Academic Knowledge vs. Practical PV Skills

A common challenge in new turnkey projects is the assumption that a general engineering degree directly translates to proficiency on the factory floor. Solar module manufacturing involves highly specialized equipment and processes that are not typically covered in standard academic courses.

The gap between theoretical knowledge and practical application is most evident in key production stages. An electrical engineer may understand the photovoltaic effect, but that knowledge doesn’t automatically equip them to operate and maintain a complex, multi-million-dollar solar cell stringer machine.

Key areas requiring specialized, hands-on training include:

-

Machine Operation: Calibrating, operating, and troubleshooting specific machines like laminators, framers, and electroluminescence (EL) testers.

-

Process Control: Understanding the precise parameters for soldering, lamination, and curing that directly impact module quality and longevity.

-

Quality Assurance: Performing specific tests, such as sun simulation and hi-pot testing, and correctly interpreting the results to identify defects.

-

Materials Handling: Managing delicate components like solar cells and EVA film to minimize breakage and contamination.

Bridging this gap is not a minor detail; it is fundamental to achieving consistent production output, high yields, and internationally recognized product certifications.

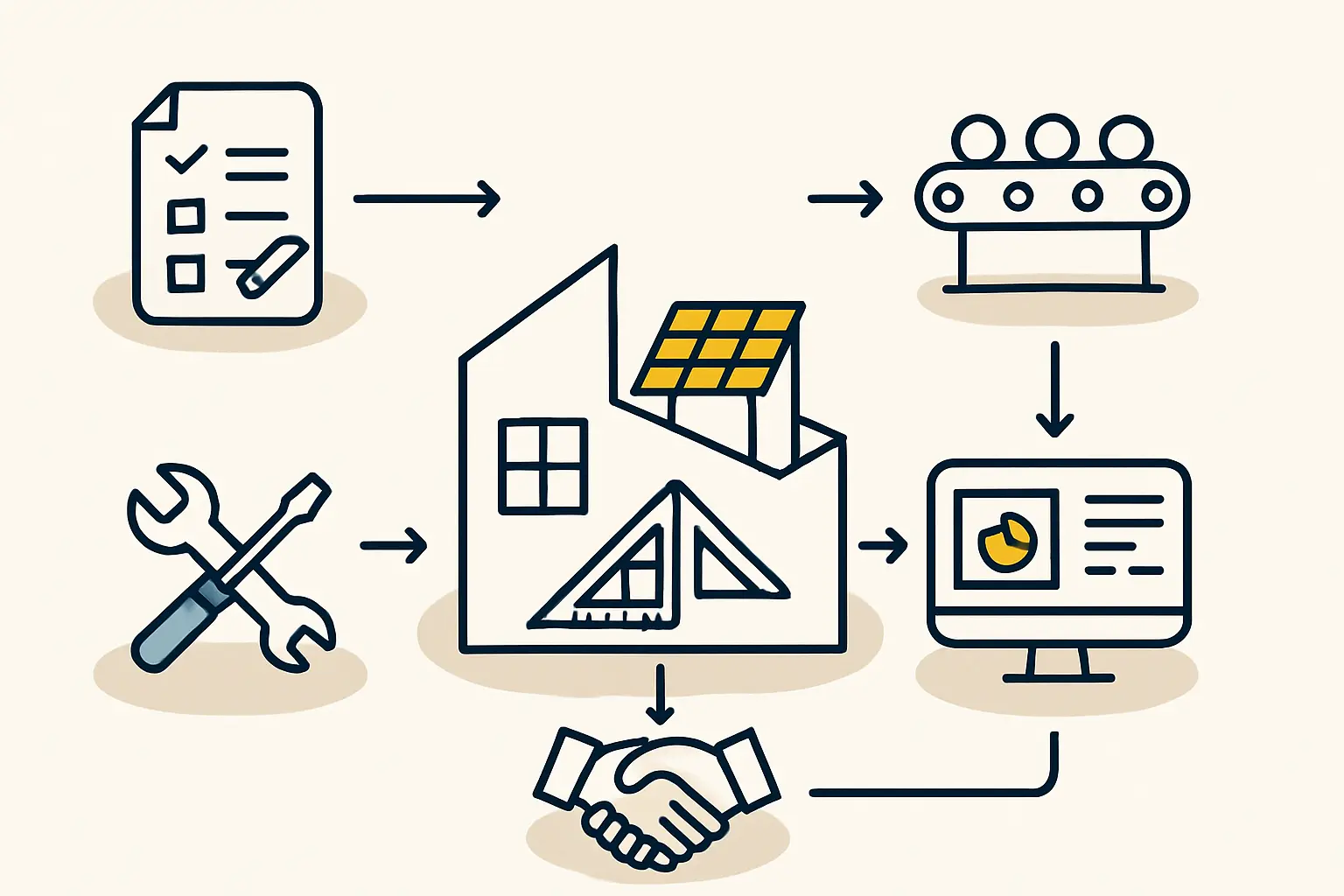

Sourcing Talent: A Three-Pronged Recruitment Strategy

A successful staffing strategy involves looking beyond a single source of talent. By combining different profiles, a factory can build a balanced team with a mix of theoretical knowledge and practical experience.

-

University Graduates

Recent graduates in electrical or mechanical engineering are ideal candidates for junior engineer or supervisor roles. Their strength lies in their strong theoretical background, adaptability, and eagerness to learn new technologies. They are best suited for roles in quality control, process engineering, and maintenance. Here, their analytical skills can be applied to optimize production and solve complex problems once they receive specific on-the-job training. -

Technicians from Adjacent Industries

Experienced technicians from established manufacturing sectors—such as automotive, electronics, or even textiles—are invaluable for operator roles. These individuals may not have a formal engineering degree but possess something equally important: an intuitive understanding of a production environment. They are accustomed to shift work, production targets, and the discipline of following standard operating procedures (SOPs). Their hands-on experience with industrial machinery often makes them faster to train on specific solar equipment. -

Initial Key Hires with Prior PV Experience

Hiring individuals with direct experience in the solar industry is crucial for critical leadership positions like Plant Manager or Head of Production. While this talent may be scarcer locally, bringing in one or two seasoned experts can accelerate the learning curve for the entire team. These leaders become the internal champions for quality standards and effective training protocols, drawing from their experience to avoid common startup mistakes. Securing this foundational expertise should be factored into the initial investment in a solar manufacturing line.

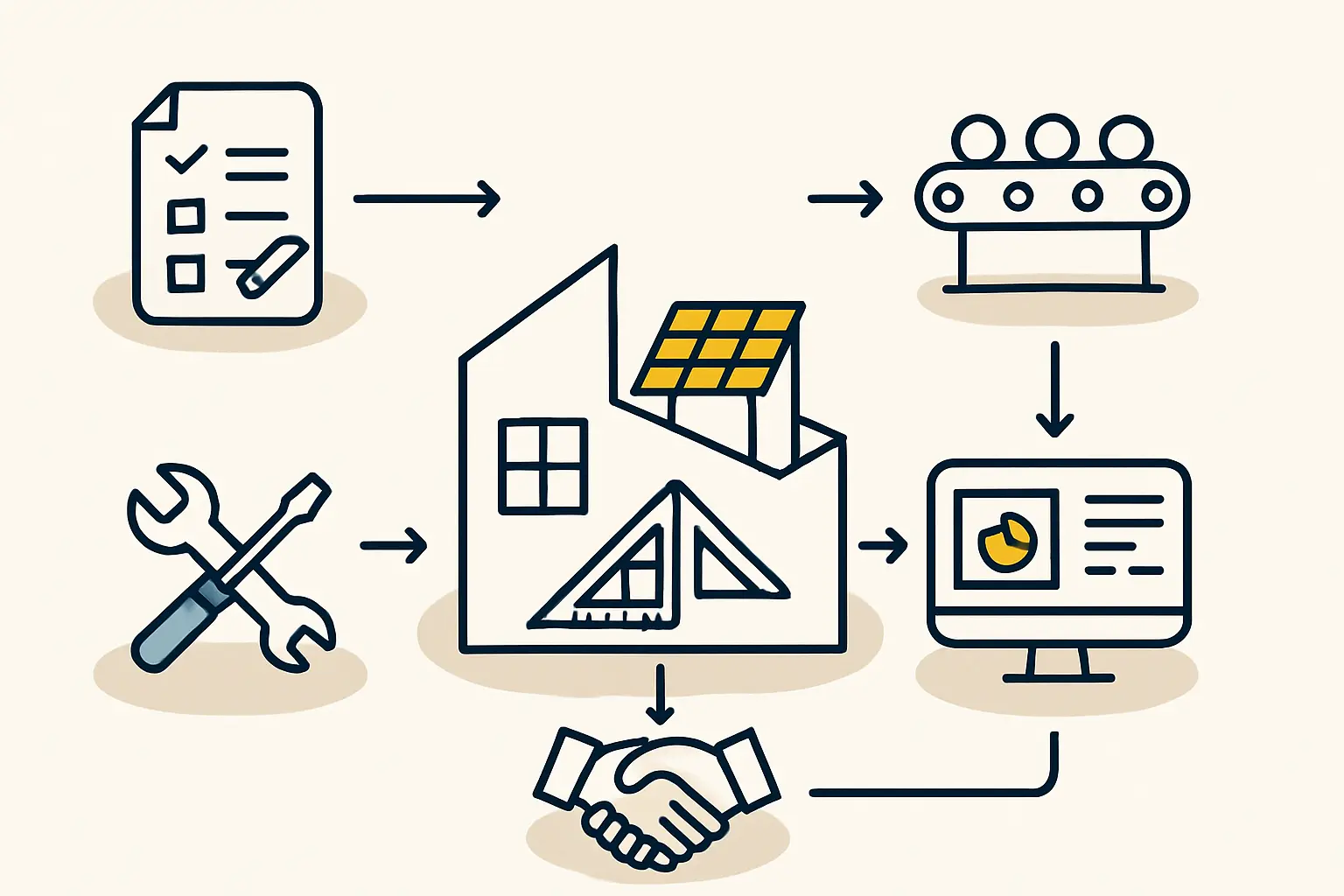

Building Competence: Designing an Effective Training Program

Recruitment is only the first step. A structured training program is essential for turning a group of new hires into a cohesive and competent production team. Experience from numerous J.v.G. turnkey projects shows that the “train-the-trainer” model is highly successful.

This method focuses on intensively training a core group of local engineers and supervisors, who then become responsible for training the machine operators and other technicians.

A comprehensive training program typically includes:

-

Theoretical Foundation: Classroom sessions covering the fundamentals of PV technology, module construction, quality standards, and safety procedures.

-

Machine-Specific Training: Hands-on instruction provided by the equipment manufacturer’s engineers. This phase covers operation, routine maintenance, and basic troubleshooting for each machine on the production line.

-

Process Integration Training: The core team learns how each step in the production sequence affects the next, ensuring they understand the entire process from cell stringing to final testing.

-

Shadowing and Supervision: The newly trained local leaders oversee the training of operators, with external experts providing support and guidance. This ensures knowledge is transferred effectively and embedded within the local organization.

This structured approach builds a self-sufficient and capable local team, embedding operational knowledge within the organization rather than leaving it dependent on external consultants. The complete setup and training for a new line can often be completed within a year, provided the factory building requirements are met on schedule.

Frequently Asked Questions about Labor and Training in Iran

How many employees are typically needed for a small-scale solar factory?

A semi-automated 50 MW production line generally requires between 20 to 30 employees per shift. This includes machine operators, quality control staff, maintenance engineers, and a shift supervisor. The total factory headcount, including administration and management, will be higher.

What are the most critical roles to fill first?

The first key hires should be the Plant Manager and the heads of Production, Quality, and Maintenance. These individuals form the core leadership team and should be involved in the subsequent hiring and training of all other personnel.

Is it better to hire experienced technicians or train new graduates?

A balanced approach is best. Hire experienced technicians from other manufacturing industries for operator roles, as they bring practical factory floor discipline. Recruit university graduates for engineering and quality roles where their theoretical background is an asset, and then invest in their specialized PV training.

What is the typical duration of an initial training program?

A comprehensive on-site training program delivered by equipment suppliers and turnkey partners typically lasts between four to eight weeks. This is followed by a period of supervised production to ensure the team can consistently meet quality and output targets.

From Potential to Performance: A Strategic Approach to Workforce Development

Iran’s large pool of engineering talent is a significant advantage for entrepreneurs entering the solar manufacturing space. However, success is not guaranteed by simply hiring individuals with diplomas. Success hinges on a deliberate and strategic investment in specialized training to bridge the gap between academic theory and the practical realities of a modern production line.

Through a thoughtful recruitment strategy and a structured, hands-on training program, a new solar enterprise can build a world-class technical team capable of producing high-quality solar modules for both domestic and international markets. This focus on human capital is the true foundation for long-term operational excellence and profitability.