When an entrepreneur considers entering the European solar market, the initial focus is often on technology and finance. Yet the success or failure of a venture often hinges on a critical, and sometimes overlooked, factor: logistics.

The ability to move finished products from factory to customer efficiently and cost-effectively isn’t a minor detail—it’s the cornerstone of a competitive business model. While manufacturing in Asia or North America may seem viable, the complexities of customs, long shipping times, and tariff uncertainties can quickly erode profitability.

This article explores a different approach—establishing a manufacturing base within the European Union. Specifically, it examines Hungary’s logistical advantages as a strategic location for a solar module manufacturing facility designed to serve the entire EU market. We will analyze how its unique geographic position and robust infrastructure can translate into significant operational efficiencies.

The Geographic Advantage: Why Location is Critical for EU Market Access

Hungary’s primary logistical advantage is its location. Situated in the heart of Central Europe, it is a member of both the European Union and the Schengen Area. This dual status provides fundamental benefits for any manufacturer.

Goods produced within Hungary can be transported to any of the other 26 EU member states without tariffs or time-consuming customs procedures. This eliminates the significant administrative burdens and cost uncertainties that plague imports from outside the bloc. Furthermore, the absence of routine border controls within the Schengen Area facilitates the free and rapid movement of goods, enabling predictable delivery schedules and reducing transit times. This access is further enhanced by the strategic value of a ‘Made in EU’ label, which can be a key differentiator in a market increasingly focused on supply chain security and local content.

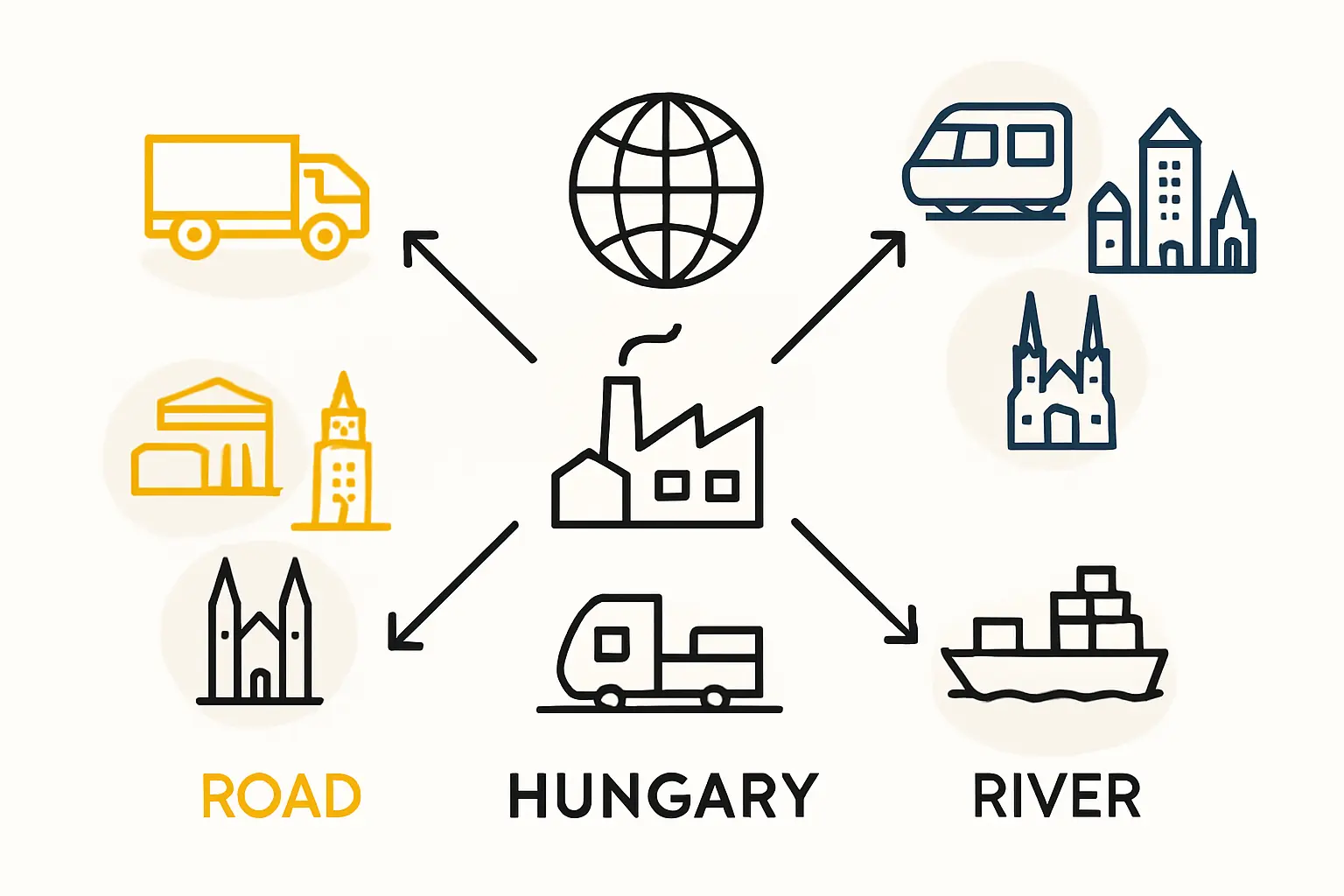

A map of Central Europe can highlight Hungary’s central position and its connections to major EU countries via road and rail networks.

From a Hungarian base, key European solar markets are within close reach. Austria, Slovakia, and Croatia are immediate neighbors, while major industrial centers in Germany, Poland, and Italy are accessible within one or two days of transport. This proximity allows manufacturers to be highly responsive to shifts in market demand.

Analyzing Hungary’s Multimodal Transport Infrastructure

A central location is only as valuable as the infrastructure that supports it. Hungary has developed a sophisticated multimodal transport system that gives businesses the flexibility to choose the most efficient method for their specific needs—be it speed, cost, or volume.

Road Freight: The Backbone of European Distribution

For time-sensitive deliveries and reaching final destinations across Europe, road transport remains the dominant mode. Hungary’s modern motorway network is well-integrated with the wider European system.

- M1 Motorway: Connects Budapest directly to Vienna and continues into the German network, providing a fast corridor to Southern Germany.

- M5 Motorway: Runs south towards Serbia, offering a primary route to markets in the Balkans.

- M7 Motorway: Provides a direct link to Slovenia and Croatia, and from there to Northern Italy.

A truck loaded with solar modules from a factory near Budapest can reach Vienna in about three hours, Munich in six to seven, and major distribution hubs in Poland or Northern Italy within a day. This rapid-response capability is essential for serving project developers operating on tight construction schedules.

Rail Freight: Efficiency for High-Volume, Long-Distance Shipments

For larger volumes and longer distances, rail offers a cost-effective and environmentally sound alternative. Hungary’s state-owned railway company and private operators like Rail Cargo Hungaria manage an extensive network connecting the country to all major European economic zones.

Modern intermodal terminals, such as the Budapest Intermodal Logistics Centre (BILK), are crucial hubs in this network. These facilities allow for the seamless transfer of containers between trucks and trains. A manufacturer can use trucks for ‘last-mile’ delivery from a local railhead, combining the flexibility of road with the long-haul efficiency of rail. This method is particularly well-suited for regular, high-volume shipments to destinations in France, the Benelux countries, or Scandinavia.

River Transport: The Cost-Effective Danube Corridor

Bisected by the Danube—Europe’s second-longest river and a major international waterway—Hungary provides a third logistical option: barge transport. While slower than road or rail, it is exceptionally cost-effective for heavy and non-urgent cargo.

The Danube waterway connects Hungary to Germany and the port of Rotterdam via the Rhine-Main-Danube Canal, and downstream to the Black Sea. This route can be used for transporting large quantities of finished modules to coastal regions or for bringing in bulk raw materials at a lower cost. Ports like Budapest, Dunaújváros, and Mohács are equipped to handle industrial cargo, adding yet another layer of flexibility to a company’s supply chain strategy.

The Business Case: Beyond Just Moving Goods

Effective logistics directly impacts a company’s financial health. By manufacturing in Hungary, a business can:

- Reduce Lead Times: Fulfilling an order for a customer in Germany or France can take days—not weeks or months.

- Lower Inventory Costs: With shorter and more predictable supply chains, businesses can operate with leaner inventories, freeing up working capital.

- Increase Responsiveness: The ability to quickly dispatch products allows a company to capitalize on short-term market opportunities.

These logistical advantages are a key component when calculating overall investment costs. While the initial capital expenditure for a factory is significant, operational savings in logistics, tariffs, and inventory management contribute directly to long-term profitability and a stronger return on investment. Experience from J.v.G. turnkey projects shows that integrating logistical planning from day one is the hallmark of a successful market entry strategy.

Frequently Asked Questions (FAQ)

How does manufacturing in Hungary compare to importing modules from Asia?

The primary advantages are logistical and strategic. Manufacturing in Hungary offers drastically shorter lead times, eliminates customs delays and import tariffs within the EU, and reduces the risk of supply chain disruptions. Furthermore, the ‘Made in EU’ designation is a powerful marketing and trust-building tool.

What are the main logistical challenges in Hungary?

Like any major European hub, road congestion can be a factor around large cities like Budapest, particularly during peak hours. Additionally, while the core rail network is strong, ongoing modernization is required on some secondary lines to increase speed and capacity. Proper planning with local logistics partners can mitigate these challenges.

Is Hungary’s infrastructure suitable for oversized or heavy components needed for a factory setup?

Yes. The country has a strong industrial base, particularly in the automotive sector, and its infrastructure is designed to handle heavy and oversized cargo. The same road, rail, and river networks used for exporting finished goods are equally capable of managing the inbound logistics for factory equipment.

Does being landlocked present a disadvantage for sea freight?

It is a trade-off. While Hungary lacks direct sea access, it has excellent and efficient rail connections to major European ports, including Koper (Slovenia), Trieste (Italy), and Hamburg (Germany). For many businesses targeting the European landmass, the benefits of the central location and EU membership outweigh the need for direct port access.

Conclusion: Integrating Logistics into Your Strategic Planning

Selecting a location for a new solar module factory is a multifaceted decision. While factors like labor costs and government incentives are important, the strategic value of logistics should never be underestimated.

Hungary offers a compelling combination: a central European location, seamless access to the EU Single Market, and a robust multimodal transport network. For entrepreneurs and investors aiming to serve the European solar market with speed, reliability, and cost-efficiency, its logistical framework provides a solid foundation for building a competitive and resilient manufacturing operation. Understanding these dynamics is a critical step in developing a business model built for long-term success.