For an entrepreneur entering the solar manufacturing industry, attention naturally gravitates toward production machinery and technology. However, a new factory’s success often depends just as much on a less visible yet critical element: its logistical framework.

The way a business manages the flow of raw materials into the factory and finished products out to market is fundamental to its operational and financial health.

This article draws on the example of Irish ports, such as Dublin and Cork, to illustrate the core principles of import-export logistics for a solar module factory. While the specifics relate to Ireland, the strategic questions and processes apply universally to any professional planning a new manufacturing venture, whether in Africa, the Middle East, or the Americas.

The Strategic Role of Ports in the Solar Supply Chain

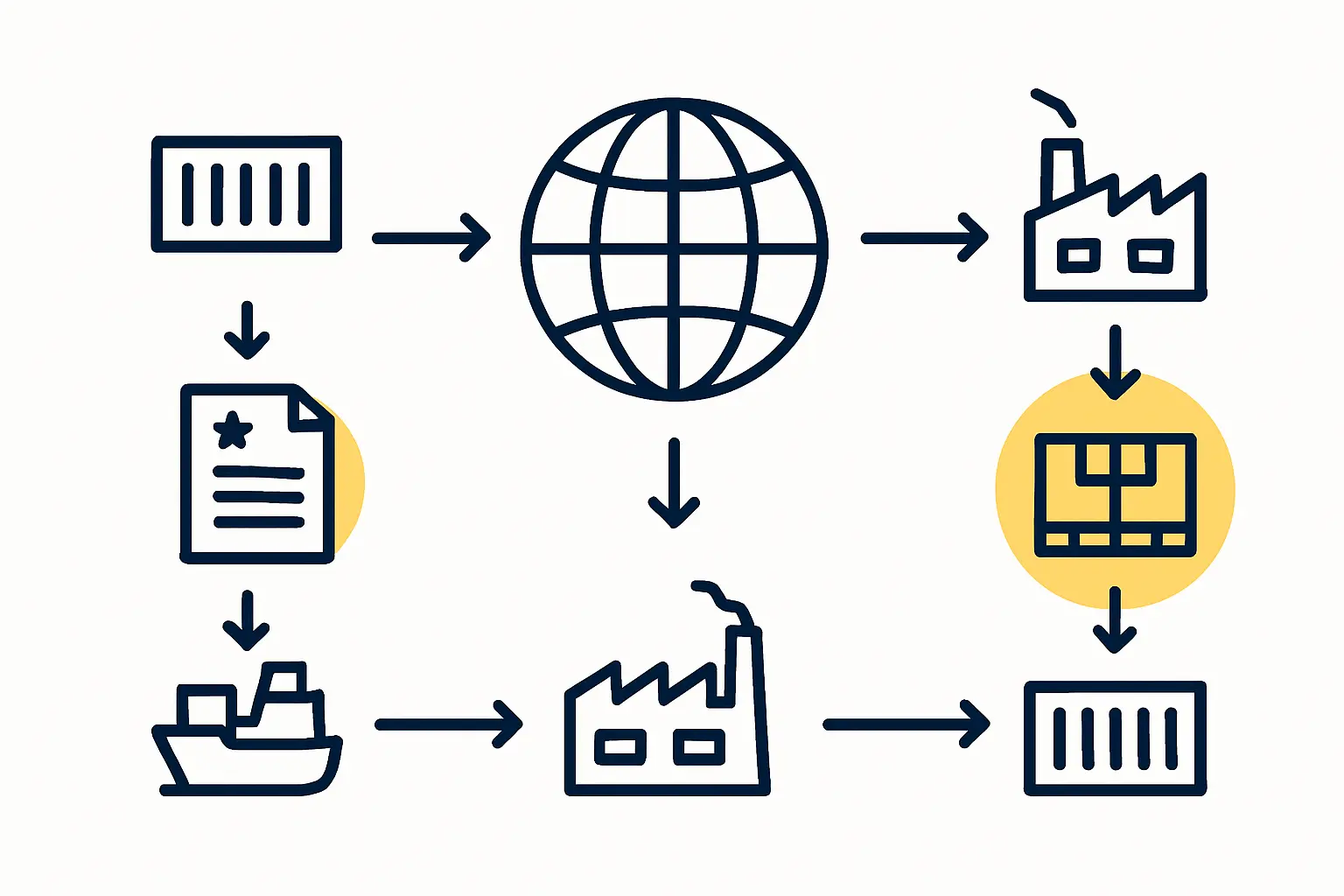

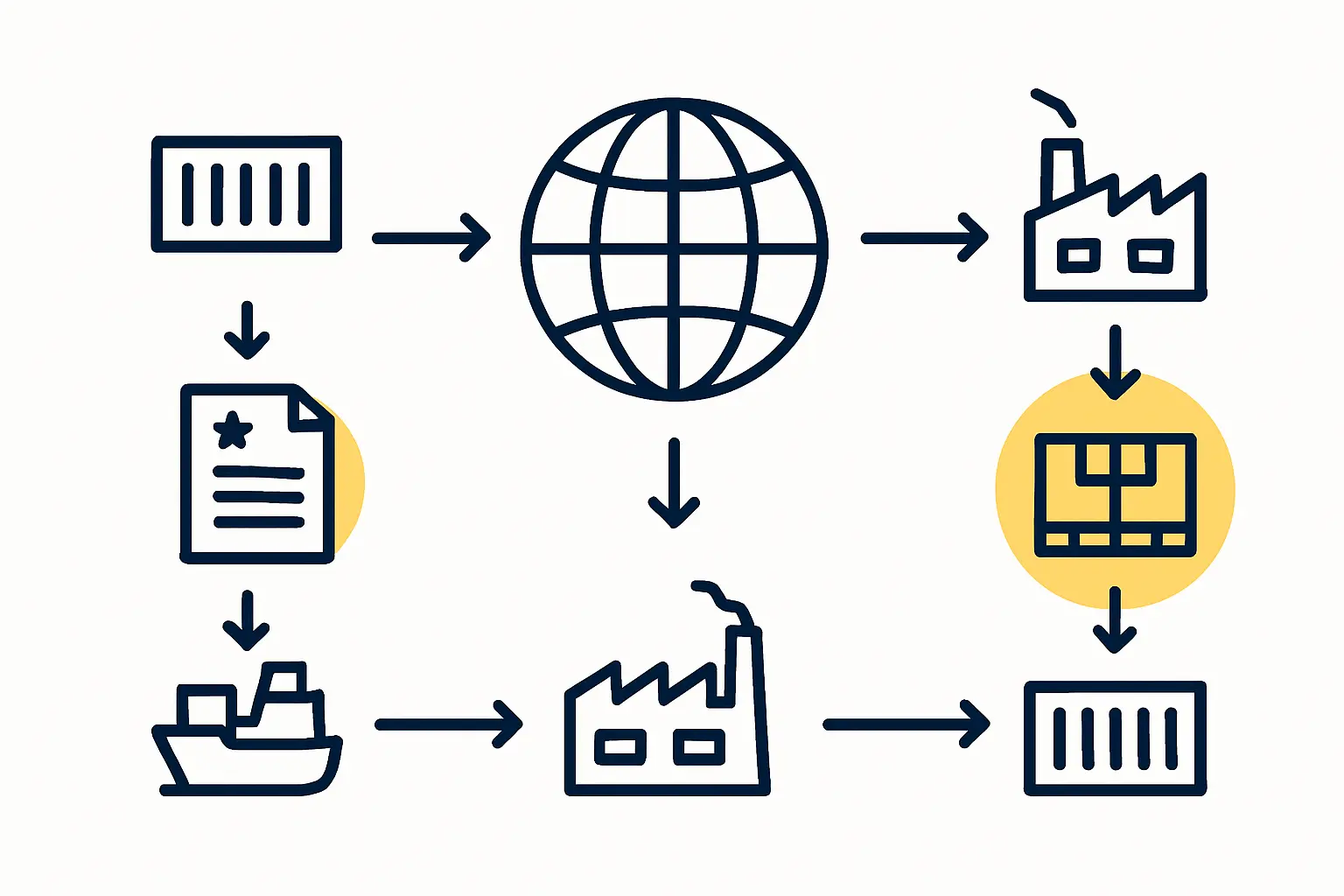

A solar module factory operates on a dual-flow logistical model: consistently importing components and reliably exporting finished goods. Ports serve as the primary gateways for this flow, and their efficiency directly impacts production schedules, costs, and profitability.

An inefficient supply chain can lead to production halts due to a lack of components or lost sales opportunities when finished modules cannot reach customers on time. A well-planned logistical strategy, on the other hand, becomes a competitive advantage.

Importing Key Components: Glass, Cells, and Frames

With the majority of solar cells and other specialized materials sourced from manufacturing hubs in Asia, a new factory needs a reliable sea freight route to bring in the necessary raw materials for production.

Taking the Port of Dublin or the Port of Cork as an example, the typical journey from a major Asian port like Shanghai or Ningbo takes approximately 30 to 40 days. These components are shipped in standard 20-foot or 40-foot containers. To put this in business terms, a single 40-foot container can typically hold enough raw materials—such as solar cells, glass, backsheets, and aluminum frames—for about 1 MW of module production.

The selection of a port is a strategic decision. The Port of Cork, for instance, is a natural deep-water harbour capable of accommodating some of the world’s largest container vessels. This capability can provide access to more direct shipping routes and potentially more competitive freight rates.

Exporting Finished Solar Modules to Global Markets

Once modules are manufactured and certified, they must be shipped to their final markets. A factory’s proximity and access to an efficient export port are crucial for reaching customers in a timely, cost-effective manner.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

From a well-connected European port like Dublin, reaching diverse international markets is straightforward. For example:

Transit to the US East Coast: Approximately 10–14 days.

Transit to major West African ports (e.g., Lagos, Tema): Approximately 15–20 days.

Transit to other European markets: Often faster via short-sea shipping or road freight.

A standard 40-foot container holds between 800 and 900 finished solar modules, depending on their size and wattage, so careful planning of container loading is essential to maximize space and minimize shipping costs per unit.

The Financial and Timeline Implications of Port Logistics

Effective logistical planning goes beyond transit times; it is a crucial factor in the financial modeling of the entire operation. A well-structured comprehensive business plan must account for these variable costs.

Deconstructing the Costs: From Freight to Final Delivery

The total cost of shipping a container involves several components, and entrepreneurs must budget for each:

-

Ocean Freight: This is the primary cost. Rates are highly volatile and influenced by global demand, fuel prices, and geopolitical events. For a 40-foot container from Asia to Europe, costs have fluctuated from approximately $2,000 before 2020 to over $15,000 during periods of major disruption. A stable market might see rates between $3,000 and $5,000, but budgeting for this volatility is critical.

-

Port Handling Fees: Known as Terminal Handling Charges (THC), these fees cover the cost of unloading the container from the ship and moving it within the port. In major European ports, this can range from €200 to €400 per container.

-

Customs & Duties: These government-levied taxes depend on product classification (HS Code) and the trade agreements between the origin and destination countries.

-

Inland Transport: This covers the cost of moving the container from the port to the factory, and later from the factory back to the port for export.

Navigating Customs and Tariffs

Customs clearance is a procedural gatekeeper that can cause significant delays if not managed correctly. While a smooth process can take as little as two to five business days, simple documentation errors—like an incorrect HS Code or a mismatched bill of lading—can lead to weeks of delays. These delays often incur demurrage fees: daily charges for a container that has not been moved out of the port on time.

Engaging a competent customs broker is not an optional expense but a necessary investment to ensure compliance and efficiency. Based on experience from J.v.G. turnkey projects, integrating a logistics and customs strategy early in the planning phase prevents costly surprises later on.

Frequently Asked Questions (FAQ) about Solar Manufacturing Logistics

What is the typical lead time for sourcing raw materials?

Factoring in production time at the supplier, sea freight transit (30-40 days from Asia), and customs clearance, a business should plan for a total lead time of 60 to 90 days from placing an order to having materials available at the factory.

How does being in a landlocked country affect logistics?

For factories in landlocked regions, logistics become more complex. The process involves sea freight to a port in a neighboring country, followed by customs transit and then road or rail transport to the final destination. This adds cost, time, and another layer of customs procedures that must be carefully managed.

What key documents are required for international shipments?

The core documents include the Bill of Lading (the contract with the shipping line), the Commercial Invoice (detailing the value of the goods), the Packing List (detailing the contents of the shipment), and a Certificate of Origin. Specific markets may require additional certifications or import permits.

How does logistics impact the overall factory investment?

Logistical costs are a key operational expenditure, but they also impact capital investment. The need for warehousing space to store a buffer stock of both raw materials and finished goods must be factored into the total investment for a solar module factory. A factory with an unreliable supply chain may need to hold several months of inventory, tying up significant working capital.

Conclusion: Integrating Logistics into Your Business Plan

The journey of a solar module begins long before it is assembled and ends long after it leaves the factory floor. The logistical framework supporting this journey is as critical as the production technology itself.

Understanding the costs, timelines, and procedural requirements of importing and exporting through major international ports allows an entrepreneur to build a resilient and competitive manufacturing operation. Logistics should not be an afterthought but a core component of the initial business strategy, ensuring the seamless flow of goods that underpins profitability and growth.