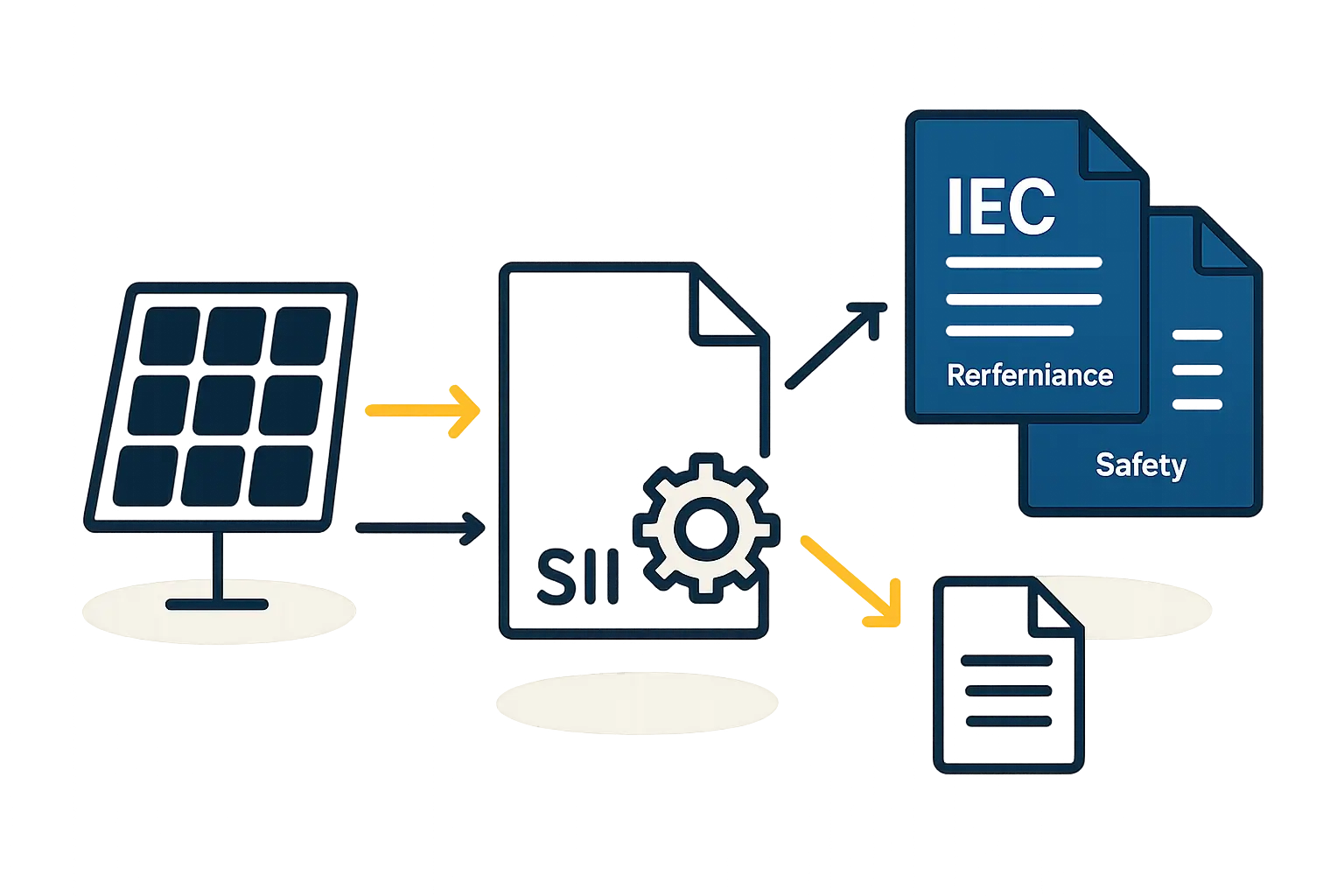

Imagine this: an entrepreneur has successfully established a new solar module production facility. The modules are excellent, manufactured to the highest international IEC standards. The first container is shipped to a promising new market—Israel—only to be held indefinitely at customs. The reason? A lack of a specific, mandatory national certification.

This kind of predicament is more common than one might expect. While global standards from the International Electrotechnical Commission (IEC) are fundamental, they are often just the starting point. Many countries, including Israel, maintain their own rigorous national standards required for market access.

For any professional aiming to supply the Israeli solar market, understanding the requirements of the Standards Institution of Israel (SII) isn’t just an advantage—it’s a necessity. This guide offers a clear overview of the SII certification landscape, its relationship with IEC standards, and the key steps a manufacturer must take to enter the Israeli market successfully.

The Dual Challenge: Global Standards and National Requirements

To operate successfully in the international solar market, manufacturers must navigate two layers of certification: the global baseline and national specifics.

The Global Benchmark: IEC Certification

IEC certification is the international benchmark for solar module safety, quality, and performance. The primary standards are:

- IEC 61215: Addresses design qualification and type approval, ensuring long-term performance under various climatic conditions.

- IEC 61730: Focuses on safety qualification, covering everything from electrical shock hazards to fire safety.

Achieving IEC certification demonstrates that a product meets global quality standards, but it doesn’t grant automatic access to every market in the world.

The National Gatekeeper: Standards Institution of Israel (SII)

The SII is Israel’s national standardization body. It prepares and enforces standards for all goods and services sold in the country, including solar PV modules. Its primary objective is to ensure product safety, quality, and compatibility with local infrastructure and environmental conditions. For solar modules, SII certification is a legal prerequisite for importation and sale.

A Closer Look at the Standards Institution of Israel (SII)

The SII’s framework for solar modules builds on IEC standards but adds specific national considerations. A manufacturer intending to sell in Israel must prove compliance with the Israeli-adopted versions of these international norms.

The key standards include:

- SI 61215 (Parts 1, 1-1, 2): This standard mirrors IEC 61215, focusing on the performance and durability of terrestrial crystalline silicon PV modules. It ensures the modules can withstand the environmental stresses they will face over their operational lifetime.

- SI 61730 (Parts 1 & 2): Aligned with IEC 61730, this standard covers the safety requirements for PV modules, ensuring they are safe for installers and the public.

- SI 60904 Series: This set of standards relates to the measurement of a PV device’s current-voltage (I-V) characteristics, ensuring that performance claims are accurate and verifiable.

Compliance with these standards isn’t a matter of self-declaration; it involves a formal, multi-stage verification process managed by the SII.

The SII Certification Process: A Step-by-Step Overview

Navigating the SII certification process requires a methodical approach. The process typically involves several key steps.

Step 1: Secure a Partnership with an Israeli Importer

This is a critical, non-negotiable first step. The SII certificate is issued to the Israeli importer, not the foreign manufacturer. A manufacturer must therefore establish a formal relationship with a local company to act as the license holder and legal representative for the product in Israel. This partner is responsible for managing the application process with the SII.

Step 2: Prepare and Submit Comprehensive Documentation

The importer, on behalf of the manufacturer, submits a detailed application package to the SII. This package must include:

- Valid IEC 61215 and IEC 61730 certificates and full test reports from an accredited laboratory.

- A detailed factory inspection report verifying that the production facility adheres to strict quality control standards.

- Complete technical specifications and datasheets for the module models intended for certification.

- Information about all critical components used in the module’s bill of materials.

Step 3: Undergo a Factory Audit

The SII must verify that the manufacturing facility can consistently produce modules that match the specifications of the units originally tested for IEC certification. An SII-appointed inspector or an approved third-party auditor will conduct an on-site inspection of the production line. The audit focuses on the Quality Management System (QMS), production controls, and traceability of materials. A well-designed facility is structured to meet these audit requirements from day one.

Step 4: Submit Samples for Testing in Israel

Even with valid IEC test reports, the SII reserves the right to conduct its own verification tests. The importer must submit sample modules from a commercial production batch to an SII-accredited laboratory in Israel. These tests confirm the modules meet specific Israeli standards and haven’t deviated from the originally certified design.

Step 5: Issuance of the SII Certificate

Once all documentation is reviewed, the factory audit is passed, and sample testing is successfully completed, the SII issues the final certificate to the Israeli importer. Only then can the solar modules be legally imported and sold in Israel.

Key Differences: How SII Requirements Align with IEC Standards

While SII standards are largely harmonized with their IEC counterparts, manufacturers must be aware of potential “national deviations.” These are specific requirements, unique to Israel, that may not be covered by standard IEC testing.

Examples of these deviations can include:

- Labeling and Marking: Specific requirements for information displayed on the module’s rating label, often including text in Hebrew.

- Environmental Durability: Potentially stricter requirements for materials to withstand Israel’s high UV radiation and arid, dusty conditions.

- Electrical Safety: Specific norms related to grounding, junction box construction, or connector types to align with local electrical codes.

Integrating these requirements efficiently without causing production bottlenecks hinges on a thorough understanding of the entire solar module production process.

Common Pitfalls for New Manufacturers Targeting the Israeli Market

Entrepreneurs entering this market for the first time often face a steep learning curve. Being aware of common challenges can prevent costly delays.

- Underestimating Timelines: The SII certification process can take several months. This timeline must be factored into any market entry strategy and sales forecast.

- Ignoring the Importer Requirement: Attempting to manage the certification process directly without a dedicated Israeli partner is impossible and will lead to a dead end.

- Inadequate Factory Documentation: A factory with a weak or poorly documented Quality Management System is a major red flag for auditors. Proper documentation is as important as the physical machinery.

- Product Design Mismatch: A module designed for a temperate climate may use materials that degrade quickly under the intense sun and heat of the Middle East. Ensuring the bill of materials is suitable for the target environment is essential.

Successfully clearing these regulatory hurdles opens the door to a mature and technologically advanced solar market.

Frequently Asked Questions (FAQ)

What is the difference between IEC and SII certification?

IEC is a global standard for safety and quality; SII certification is a mandatory national requirement for selling solar modules in Israel. The SII uses IEC standards as its baseline but adds national deviations and its own verification processes.

Can a factory get SII certification without an Israeli partner?

No. The SII certificate is issued to the local Israeli importer, who acts as the legal license holder for the product. A foreign manufacturer must partner with an Israeli entity to apply for the certification.

How long does the SII certification process typically take?

The timeline can vary significantly depending on the completeness of the documentation, factory audit scheduling, and SII lab testing queues. A manufacturer should plan for a process that can last from four to nine months.

Do my modules need re-testing in Israel if they are already IEC certified?

Yes, in most cases. The SII requires verification testing of production samples at its own accredited laboratories to confirm compliance with Israeli standards and ensure consistency with the original type-approval tests.

What happens if a factory fails the SII audit?

If an audit reveals non-conformities, the factory will be given a specific timeframe to implement corrective actions. A follow-up audit will be required to verify that the issues have been resolved before the certification process can continue. This can lead to significant delays and costs.

Planning for Success in Regulated Markets

Entering a highly regulated market like Israel requires more than just a quality product; it demands a strategic approach to compliance. National certifications like the SII are not simply bureaucratic hurdles; they are an integral part of a successful market entry strategy.

By understanding the requirements early, selecting the right local partners, and ensuring that production processes are robust and well-documented, a new manufacturer can navigate this complex landscape effectively. Integrating these regulatory milestones into the initial business plan is the most reliable path to avoiding costly delays and building a sustainable presence in valuable international markets.