An entrepreneur planning his first solar module factory has carefully planned every aspect of the production line, from the stringer to the final laminator. The building blueprints are ready, and the budget seems robust.

However, a preliminary review with local authorities in Israel reveals a fundamental missing component: a comprehensive security and defense infrastructure, including mandatory protected spaces for all employees. This oversight leads to a significant redesign, a 12% increase in construction costs, and a six-month delay.

This scenario is more common than many international investors realize. In Israel, security is not an optional extra or a final touch; it is a foundational element of industrial planning, mandated by law and essential for operational resilience. For any business professional looking to establish a solar manufacturing facility in the region, understanding and integrating these requirements from day one is critical to the project’s success.

This guide outlines the key security considerations, regulatory bodies, and practical steps for embedding security into your facility’s design and budget.

Why Security is a Foundational Pillar, Not an Add-On

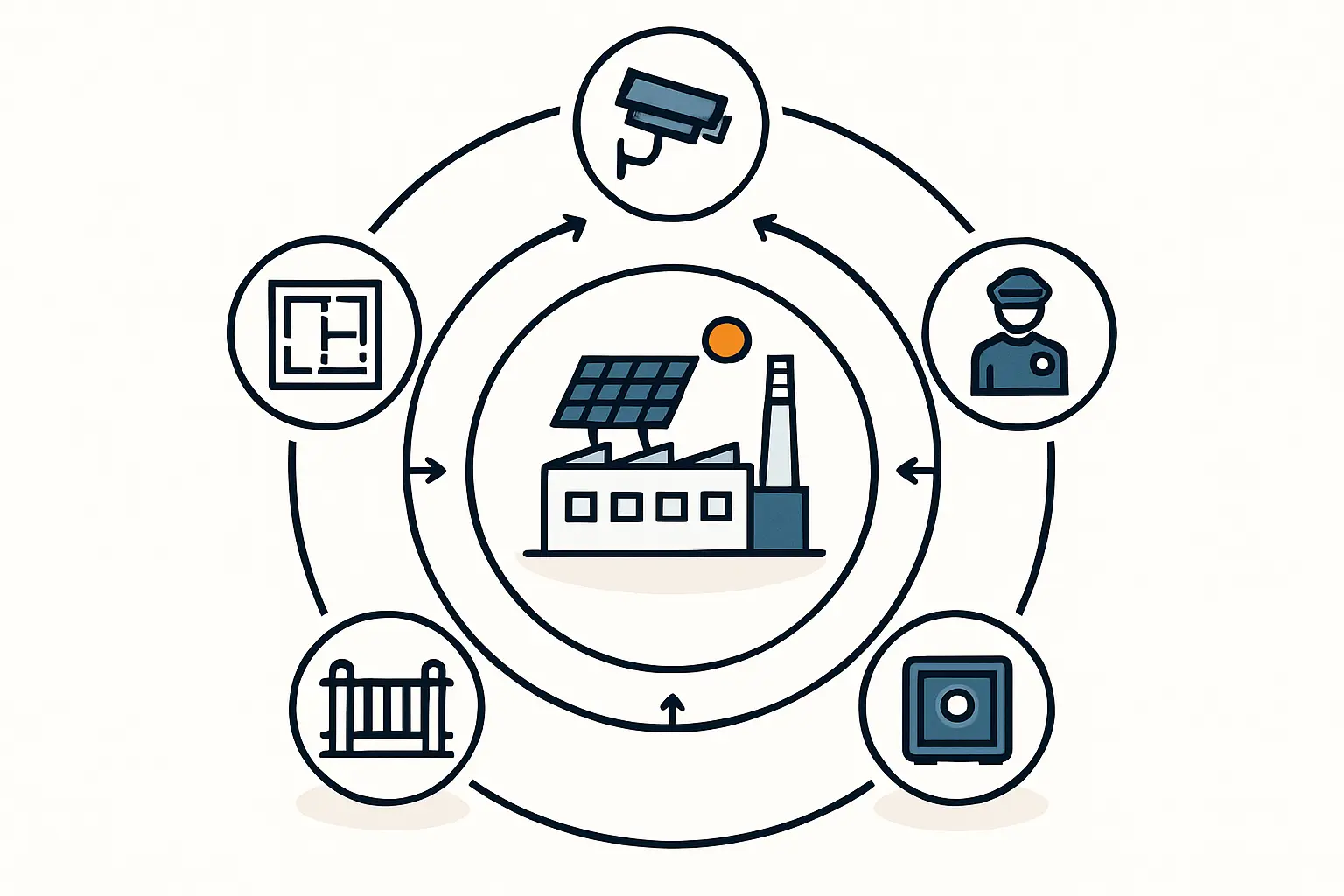

In many parts of the world, industrial security focuses primarily on preventing theft or unauthorized access. In Israel, the scope is far broader, encompassing national security considerations and civil defense protocols. The process is overseen by several key authorities, including the Israel Police, the Home Front Command (Pikud Ha’Oref), and in some cases, the Shin Bet (Israel Security Agency).

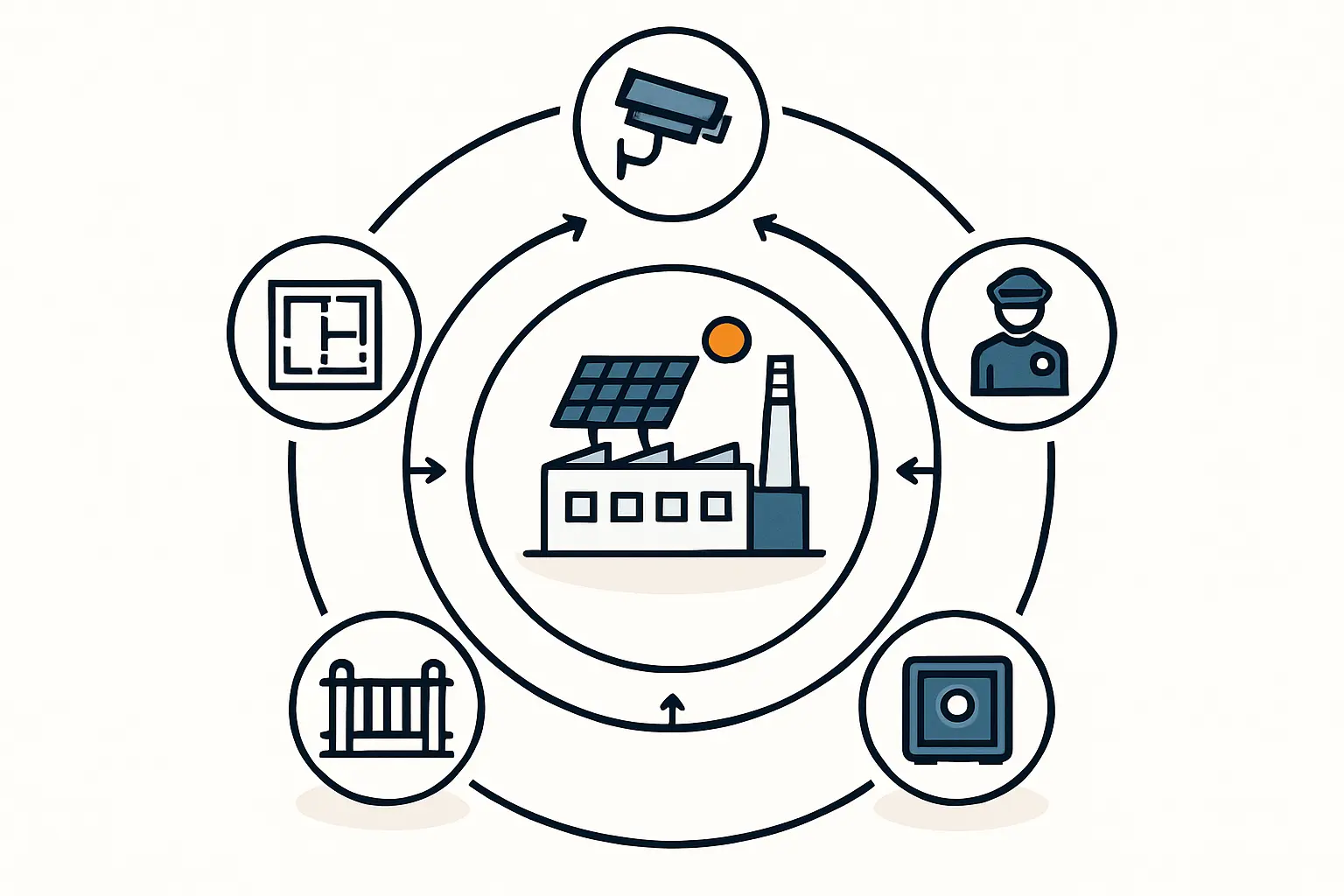

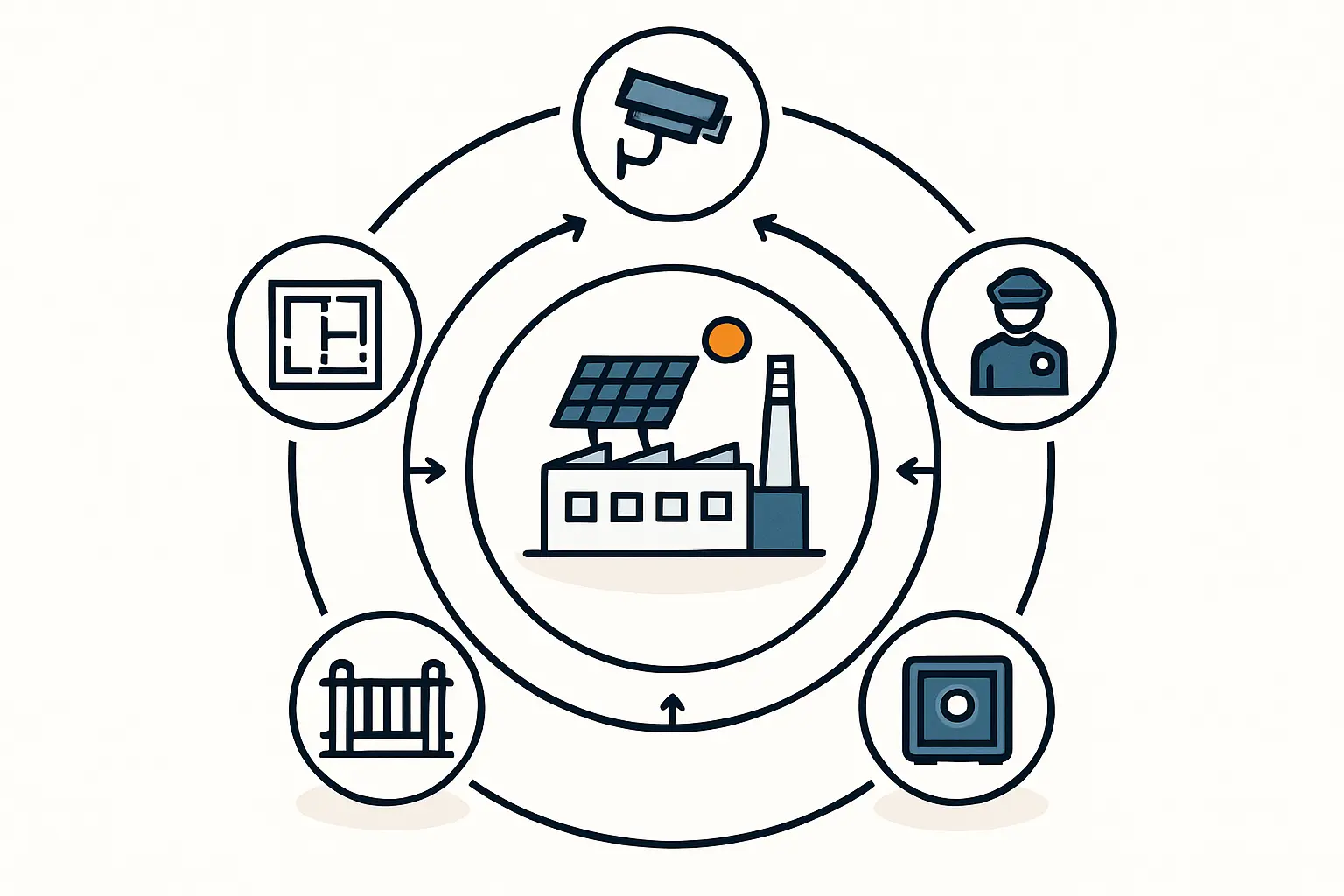

For a solar module manufacturing plant, typically classified as a standard-risk facility, compliance involves a multi-layered approach. The goal is to protect personnel, safeguard high-value assets like manufacturing equipment, and ensure production continuity.

Neglecting this at the outset of your solar factory layout design is one of the costliest mistakes an investor can make, forcing expensive retrofitting and potentially delaying operational permits indefinitely.

Key Components of a Secure Facility Design

A robust security plan is woven into the building’s architecture and operational flow, with several interconnected layers.

Perimeter and Access Control

The first line of defense is the facility’s perimeter. In Israel, this typically means more than a simple fence. Industrial sites often require ‘smart’ fencing integrated with sensors that can detect attempts to climb, cut, or tamper with the barrier.

Equally important is managing who and what enters the site. This involves:

- Controlled Vehicle Entry: Designated, fortified checkpoints for trucks and employee vehicles, often with under-vehicle inspection capabilities.

- Personnel Access Systems: Using key cards or biometric scanners to ensure only authorized individuals can access sensitive areas like the production floor, server rooms, or raw material storage.

- Secure Loading Docks: Designing loading and unloading zones that are isolated from the main production area to prevent unauthorized entry.

Surveillance and Monitoring

Effective surveillance is about deterrence and response. A modern system includes:

- CCTV Network: High-resolution cameras covering the perimeter, entry points, parking areas, and critical interior zones.

- Video Analytics: Intelligent software that can automatically detect unusual activity—such as a person loitering near a fence or a vehicle parked in a restricted zone—and alert security staff.

- All-Weather Capability: Thermal or infrared cameras for effective monitoring at night or in adverse weather conditions.

- Strategic Lighting: Proper illumination is a powerful deterrent, eliminating blind spots and ensuring surveillance systems can function effectively 24/7.

Mandatory Protected Spaces (Mamad/Miklat)

Perhaps the most unique requirement for industrial facilities in Israel is the construction of protected spaces, known as a Mamad (residential protected room) or Miklat (shelter). These structures, mandated by the Home Front Command, are designed to protect employees from rocket or missile attacks.

The shelter’s size and specifications are not arbitrary; they are calculated based on the maximum number of people on-site at any given time. These are not simple concrete rooms—they require reinforced walls, specialized ventilation systems, and secure doors. Integrating a Miklat into the architectural plans from the beginning is non-negotiable and has a substantial impact on the building’s structure and cost.

The Financial Implications of Security Integration

For business professionals, understanding the financial impact is paramount. A comprehensive security infrastructure is a significant capital expenditure that must be factored into the initial business plan.

Budgeting for Security

Based on experience from J.v.G. Technology GmbH turnkey projects and regional data, investors should anticipate that security infrastructure will add between 5% and 15% to the total construction costs. This percentage can vary significantly depending on the facility’s location. A factory near a high-risk border, such as Gaza or Lebanon, will face far stricter—and more expensive—requirements than one in central Israel.

This investment is a core part of the overall cost to start a solar factory and should be clearly itemized in financial projections.

Impact on Operational Costs and Insurance

Beyond the initial build-out, security has ongoing operational costs, including:

- Salaries for trained security personnel.

- Maintenance contracts for surveillance and access control systems.

- Regular security drills and training for employees.

However, this investment can yield financial benefits. A facility that meets or exceeds regulatory security standards is often viewed more favorably by insurance providers, potentially leading to lower premiums for property and business interruption insurance. This proactive approach demonstrates to insurers that the business has taken concrete steps to mitigate foreseeable risks.

A Practical Perspective from Past Projects

A common challenge is underestimating the spatial and structural requirements for a Miklat. An investor may allocate floor space for production machinery without realizing that a significant, centrally located area must be reserved for a reinforced shelter. This forces a complete rethinking of the internal layout, often compromising production flow efficiency.

Another frequent oversight is in the digital realm. While physical security is paramount, the cybersecurity of the production line’s control systems (SCADA) is just as critical. Protecting these systems from remote threats is an integral part of a facility’s overall security posture. Integrating these security protocols during the initial planning phase is far more effective and less costly than attempting to add them after the fact.

Frequently Asked Questions (FAQ)

What is a ‘Mamad’ and is it truly mandatory for a factory?

A Mamad (or Miklat for a public/industrial building) is a reinforced shelter designed to protect occupants from explosions and shrapnel. Its construction is mandated by Israel’s Home Front Command for all new buildings, including industrial facilities. The exact specifications depend on the building’s size, purpose, and location.

How much should I budget for security in my initial business plan?

As a rule of thumb, allocate 5-15% of your total construction budget for security infrastructure. This figure should be refined after consulting with local security experts and authorities, as your specific location is the biggest factor.

Does the factory’s location within Israel affect security requirements?

Yes, absolutely. A facility in a designated ‘conflict-proximate’ area will face substantially higher security requirements from the Home Front Command and Israel Police. This can include thicker reinforced concrete for shelters, more advanced perimeter fencing, and a larger security staff.

Can security measures be implemented after the factory is built?

While some systems can be retrofitted, it is extremely inefficient and costly. Major structural elements like a Miklat cannot be easily added later. Attempting to do so leads to massive project delays, budget overruns, and ultimately prevents you from obtaining the necessary operating permits.

Conclusion and Next Steps

For any entrepreneur or company planning to enter the solar manufacturing sector in Israel, security is not a line item—it is the foundation upon which a resilient and successful business is built. By treating security as an integral part of the initial design phase, you can avoid costly delays, ensure regulatory compliance, and create a safe environment for your employees and assets.

Your first step should be to engage with local security consultants and relevant authorities early in the process. Integrating these unique regional requirements into your solar business plan from the start will ensure a smoother, more predictable, and ultimately more successful project launch.