An entrepreneur has identified Kenya as a promising market for solar module manufacturing. The country’s robust GDP growth, strategic position in East Africa, and government support for renewable energy create a compelling business case. However, the initial decision to invest in Kenya raises a more complex question: where exactly should the factory be located? This single decision can profoundly influence the entire business model, affecting everything from logistics costs and talent acquisition to the final price of the solar module.

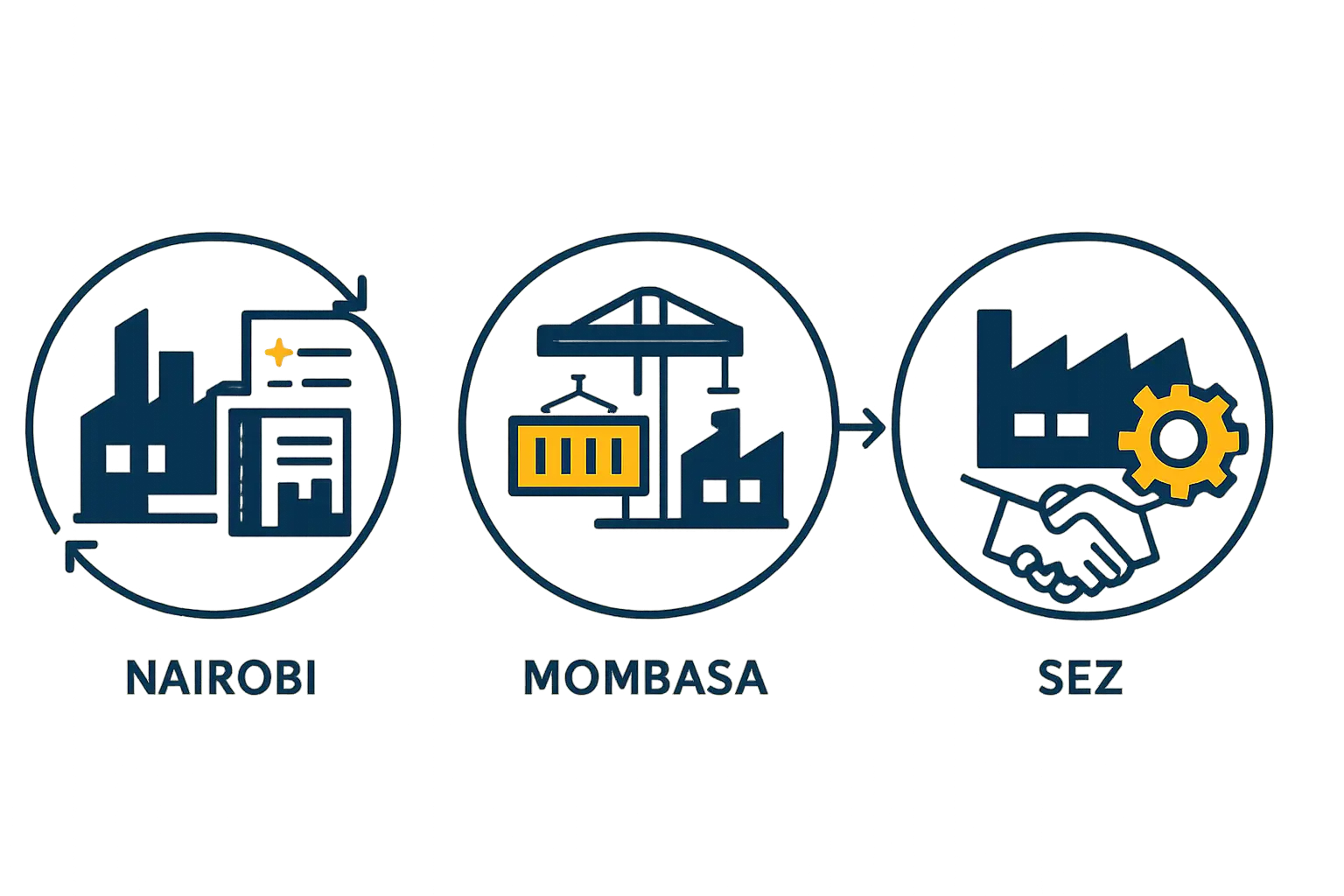

This analysis compares the leading location options for a solar manufacturing facility in Kenya: the port city of Mombasa, the capital city of Nairobi, and the country’s designated Special Economic Zones (SEZs). Understanding the distinct advantages and disadvantages of each is crucial for building a successful enterprise.

The Three Primary Location Strategies

The choice of location is not merely about finding a plot of land; it is a strategic decision that aligns the factory’s operations with its business objectives. In Kenya, three distinct geographical strategies emerge, each with a unique profile.

Mombasa: The Gateway for Imports and Exports

Mombasa is home to the largest and busiest port in East and Central Africa, making it the logistical heart of the region. For a solar module factory, which relies heavily on imported raw materials such as solar cells, glass, and aluminum frames, proximity to the port is a significant advantage.

Key Advantages:

- Reduced Inbound Logistics Costs: Locating in or near Mombasa minimizes the cost and complexity of transporting raw materials from the port to the factory. This can lead to substantial savings and a more resilient supply chain.

- Export-Oriented Potential: For businesses aiming to serve the wider East African Community (EAC) or other international markets, a Mombasa location provides a direct and efficient route for exporting finished modules.

- Established Industrial Infrastructure: As a long-standing industrial and logistics hub, Mombasa offers a well-developed infrastructure tailored to manufacturing and trade.

However, this logistical advantage should be weighed against potential challenges, such as the distance from the country’s primary domestic market and the concentration of specialized technical talent in the capital.

Nairobi: The Commercial and Talent Hub

As Kenya’s political and commercial capital, Nairobi is the center of the domestic market and home to the country’s leading universities and technical institutes. This positioning offers a different set of strategic advantages, centered on talent, market access, and administrative efficiency.

Key Advantages:

- Access to Skilled Labor: Nairobi’s concentration of universities ensures a steady supply of engineers, technicians, and managers. For a technically demanding operation like solar module manufacturing, this deep talent pool is a critical asset.

- Proximity to the Domestic Market: The majority of Kenya’s commercial and industrial activity is centered around Nairobi. A factory here gains direct access to the largest B2B and B2C markets in the country, reducing domestic distribution costs.

- Administrative Hub: Being close to government ministries, regulatory bodies, and financial institutions can simplify administrative processes, from licensing to financing.

The main trade-off for choosing Nairobi is the added cost and time required to transport imported raw materials from Mombasa. While the Standard Gauge Railway (SGR) has improved this link, it still represents an additional logistical step.

Special Economic Zones (SEZs): The Financial Incentive

Kenya has actively promoted the development of Special Economic Zones to attract foreign investment and stimulate manufacturing. These zones offer a powerful package of financial incentives that can fundamentally change the business case for a new factory. Notable SEZs include those in Naivasha, Tatu City, and Dongo Kundu (near Mombasa).

Key Advantages:

- Significant Tax Benefits: SEZs typically offer a 10-year corporate and withholding tax holiday, followed by a reduced rate. They also provide exemptions from VAT and import duties on raw materials and machinery. These incentives dramatically reduce the initial capital outlay and ongoing operational costs.

- Streamlined Processes: SEZs are designed to be business-friendly environments, often with simplified customs procedures, one-stop-shop administrative services, and reliable infrastructure.

- Plug-and-Play Infrastructure: Many SEZs offer serviced plots with pre-installed utilities like power, water, and fiber optic connectivity, reducing the time and investment needed to meet factory building requirements.

The crucial factor when considering an SEZ is its location. An SEZ near Mombasa, like Dongo Kundu, combines fiscal benefits with port access, while one near Nairobi offers tax advantages alongside proximity to the capital’s talent pool.

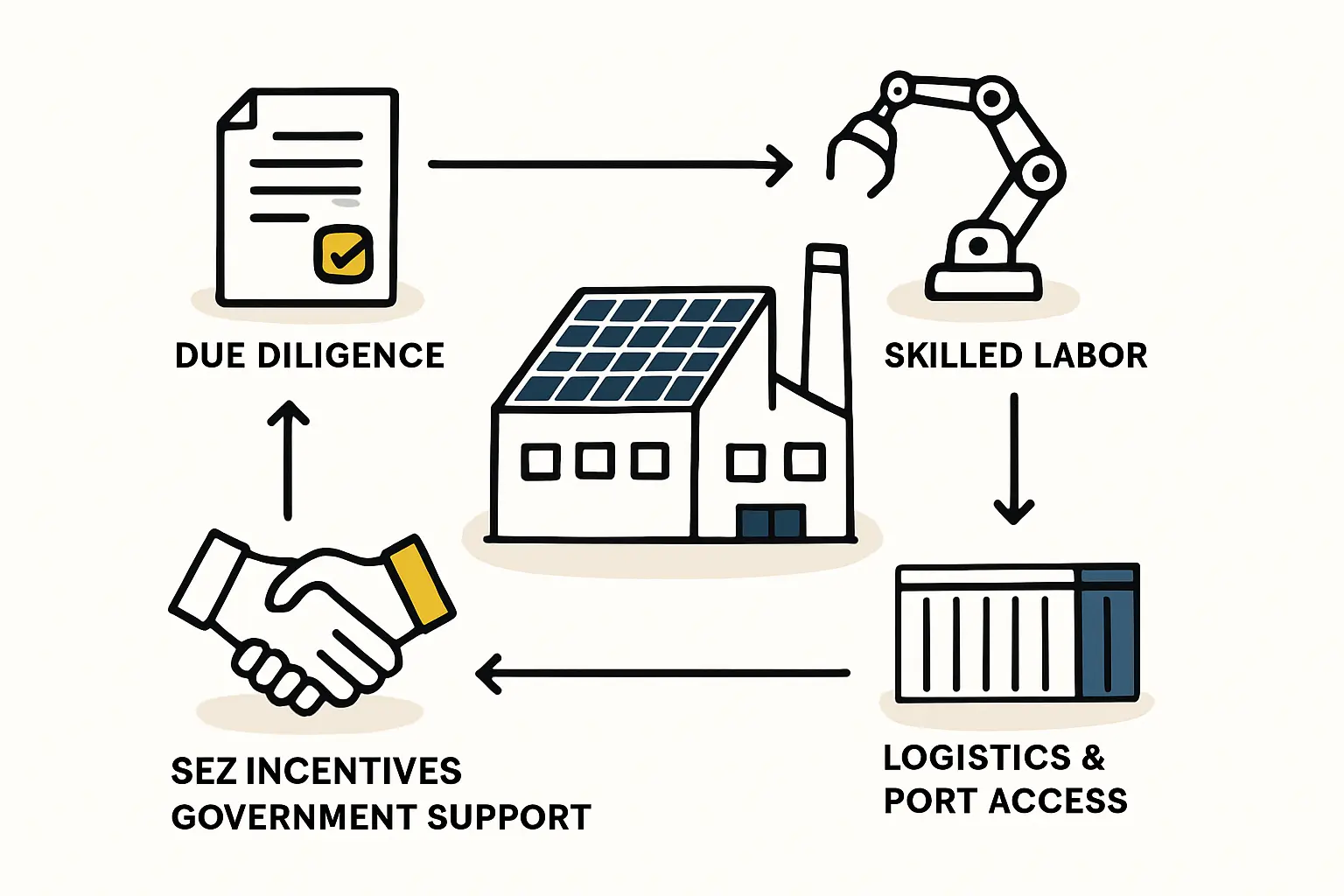

A Comparative Analysis of Key Decision Factors

To make an informed decision, investors must weigh these locations against the critical factors that drive a manufacturing business.

1. Logistics and Supply Chain

- Mombasa: The clear winner for import-dependent and export-oriented models. Direct access to the port minimizes demurrage risks, transport costs, and supply chain delays.

- Nairobi: Viable due to the SGR, but adds a logistics leg of approximately 470 km. This translates to higher costs and longer lead times for raw materials compared to a Mombasa-based competitor.

- SEZs: The logistical profile depends entirely on the SEZ’s location. Dongo Kundu SEZ offers the best of both worlds: port proximity and fiscal incentives.

2. Labor and Expertise

With Kenya’s manufacturing wages already competitive, the key differentiator becomes access to specialized skills.

- Nairobi: Unmatched access to a deep pool of technical and managerial talent from local universities and established industries. This is crucial for meeting the complex staffing requirements of a modern solar factory.

- Mombasa: Has a skilled workforce for logistics and traditional manufacturing, but may require more effort to recruit specialized PV engineering talent compared to Nairobi.

- SEZs: Recruiting can be a challenge if located in remote areas. However, SEZs like Tatu City (near Nairobi) are strategically positioned to attract skilled professionals.

3. Operational Costs and Investment

The initial investment for a solar module factory is significant, and ongoing operational costs determine long-term profitability.

- Electricity: A major operational expense. With average industrial electricity costs in Kenya around US$0.20 per kWh, any savings are significant. Grid reliability can also be a concern, often necessitating investment in backup power solutions.

- SEZs: On this front, SEZs provide a decisive advantage. The exemption from import duties on capital equipment and the 10-year tax holiday can significantly improve the project’s internal rate of return (IRR) and shorten the payback period. Based on experience from J.v.G. turnkey projects, the financial model for an SEZ-based factory is often substantially more attractive.

Conclusion: Aligning Location with Business Strategy

There is no single “best” location for a solar factory in Kenya. The optimal choice depends directly on the entrepreneur’s business model.

- An export-focused model serving the wider EAC region would benefit most from Mombasa or a coastal SEZ like Dongo Kundu.

- A domestic-market-focused model prioritizing talent and access to local B2B clients would find Nairobi or a nearby SEZ like Tatu City to be a stronger choice.

- For any investor, the financial incentives offered by Special Economic Zones are a compelling factor that should be central to the evaluation process.

A careful analysis of these trade-offs is fundamental to de-risking the investment and positioning the venture for sustainable success in one of Africa’s most dynamic markets.

Frequently Asked Questions (FAQ)

Q1: How critical is proximity to the port for raw material imports?

Proximity is critical for cost control and supply chain stability. While the SGR makes a Nairobi location feasible, the added transport costs, potential for delays, and administrative hurdles of inland transport should be carefully factored into the operational budget.

Q2: Are the tax benefits in an SEZ really significant enough to influence the location decision?

Yes, absolutely. A 10-year corporate tax holiday and exemptions on VAT and import duties can save millions of dollars over the first decade of operation. This capital can be reinvested into expansion, technology upgrades, or marketing, providing a substantial competitive advantage.

Q3: Is it difficult to find qualified technical staff outside of Nairobi?

While Nairobi has the highest concentration of technical talent, recruiting for other locations is certainly possible. However, a factory in Mombasa or a more remote SEZ may need to offer more competitive compensation packages or invest in relocation support and in-house training programs to attract and retain the required expertise.

Q4: What about infrastructure reliability like power and water in these locations?

Infrastructure is a key consideration across Kenya. While major hubs like Nairobi and Mombasa have better infrastructure than rural areas, power outages can still occur. SEZs often provide enhanced reliability with dedicated power substations and water supply, but any business plan should include a contingency for backup power generation.

Q5: Can pvknowhow.com assist in evaluating these location options?

pvknowhow.com provides structured guidance and educational materials, including a free e-course, that help entrepreneurs understand these critical early-stage decisions. For detailed feasibility studies and business planning, we offer consultancy services based on decades of experience in setting up turnkey solar factories.