An entrepreneur secures financing, procures land, and begins planning a new solar module assembly factory in Kenya. With a solid business plan, clear market demand, and the initial investment in place, everything seems on track. Yet, a critical oversight could render every module produced unsellable within the country: failing to account for the mandatory certification process with the Kenya Bureau of Standards (KEBS).

This scenario is more common than many new investors realize. While setting up production is a significant undertaking, achieving local compliance is the crucial step that grants access to the market. For locally assembled solar modules in Kenya, this means navigating the KEBS certification process.

This guide provides a clear overview of the steps, standards, and strategic considerations required to successfully obtain KEBS certification for your products.

Why KEBS Certification is a Critical Business Asset

In a market where many solar products are substandard or counterfeit, KEBS certification is not merely a regulatory hurdle; it is a powerful mark of quality and a fundamental requirement for market entry.

The Kenyan government actively encourages local assembly to build domestic capacity and create jobs. Adhering to national standards is central to this policy, ensuring that locally produced goods meet stringent quality and safety benchmarks.

For a new manufacturer, the KEBS “Diamond Mark of Quality” serves two primary purposes:

-

Market Access: It is a legal requirement for selling solar modules in Kenya. Without it, products cannot be legally sold or distributed.

-

Competitive Advantage: It immediately differentiates your products from low-quality imports, building trust with distributors, installers, and end customers.

Understanding and integrating the certification process into your initial business plan is critical for a timely and successful market launch.

Understanding the Core Standards for Solar Modules

KEBS has adopted standards based on the globally recognized International Electrotechnical Commission (IEC) framework. For crystalline silicon terrestrial photovoltaic (PV) modules, two standards are paramount:

-

KS IEC 61215: Design Qualification and Type Approval. This standard focuses on a solar module’s performance. It tests for factors like thermal performance, UV exposure, humidity and freeze resistance, and mechanical load endurance. In essence, it answers the question: “Does the module perform as specified and can it withstand long-term environmental stress?”

-

KS IEC 61730: PV Module Safety Qualification. This standard addresses the safety aspects of the module, covering electrical and fire safety. It answers the critical question: “Is the module safe for installers and users over its entire service life?”

Compliance with both standards is mandatory. Your entire operation—from material selection and manufacturing processes to quality control systems—must be designed to consistently produce modules that meet these requirements.

The KEBS Certification Process: A Step-by-Step Breakdown

The journey to certification is a structured process involving documentation, inspection, and testing. While timelines can vary, a well-prepared applicant can navigate the stages efficiently. Based on experience from J.v.G. turnkey projects, planning for certification right from the start is the most effective approach.

Step 1: Application and Documentation Submission

The process begins with a formal application to KEBS. This requires submitting a comprehensive package of technical and administrative documents, which typically includes:

- Company registration documents.

- Detailed product specifications and design drawings.

- A list of all raw materials and components used (Bill of Materials).

- Descriptions of the manufacturing process and in-house quality control procedures.

- Internal test reports, if available.

Incomplete or inaccurate documentation is a common cause of delays. Preparing these materials meticulously is key to avoiding setbacks.

Step 2: The Factory Audit

Once the documentation is reviewed and deemed complete, KEBS will schedule a physical inspection of your manufacturing facility. The audit’s goal is to verify that your factory can consistently produce modules that meet the required standards.

Inspectors will assess several key areas:

- Quality Management System: Is there a documented system for managing quality at every stage?

- Production Process Control: Are the manufacturing steps controlled and monitored?

- Calibration of Equipment: Are testing and measurement devices properly calibrated and maintained?

- Traceability: Can you trace a finished module back to the raw materials used in its production?

A well-planned solar module assembly line, complete with integrated quality control stations and standardized procedures, is fundamental to passing this audit.

Step 3: Product Sampling and Laboratory Testing

During or after the factory audit, KEBS officials will select sample modules directly from your production line for independent testing. These samples are sent to a designated laboratory—either KEBS’s own or an accredited third-party lab—to be tested against the KS IEC 61215 and KS IEC 61730 standards.

This is the most technical phase of the process. The modules undergo a series of rigorous tests, including light-soaking, thermal cycling, damp-heat exposure, and electrical safety checks. This step validates that the product’s real-world performance and safety match the design specifications provided in your application.

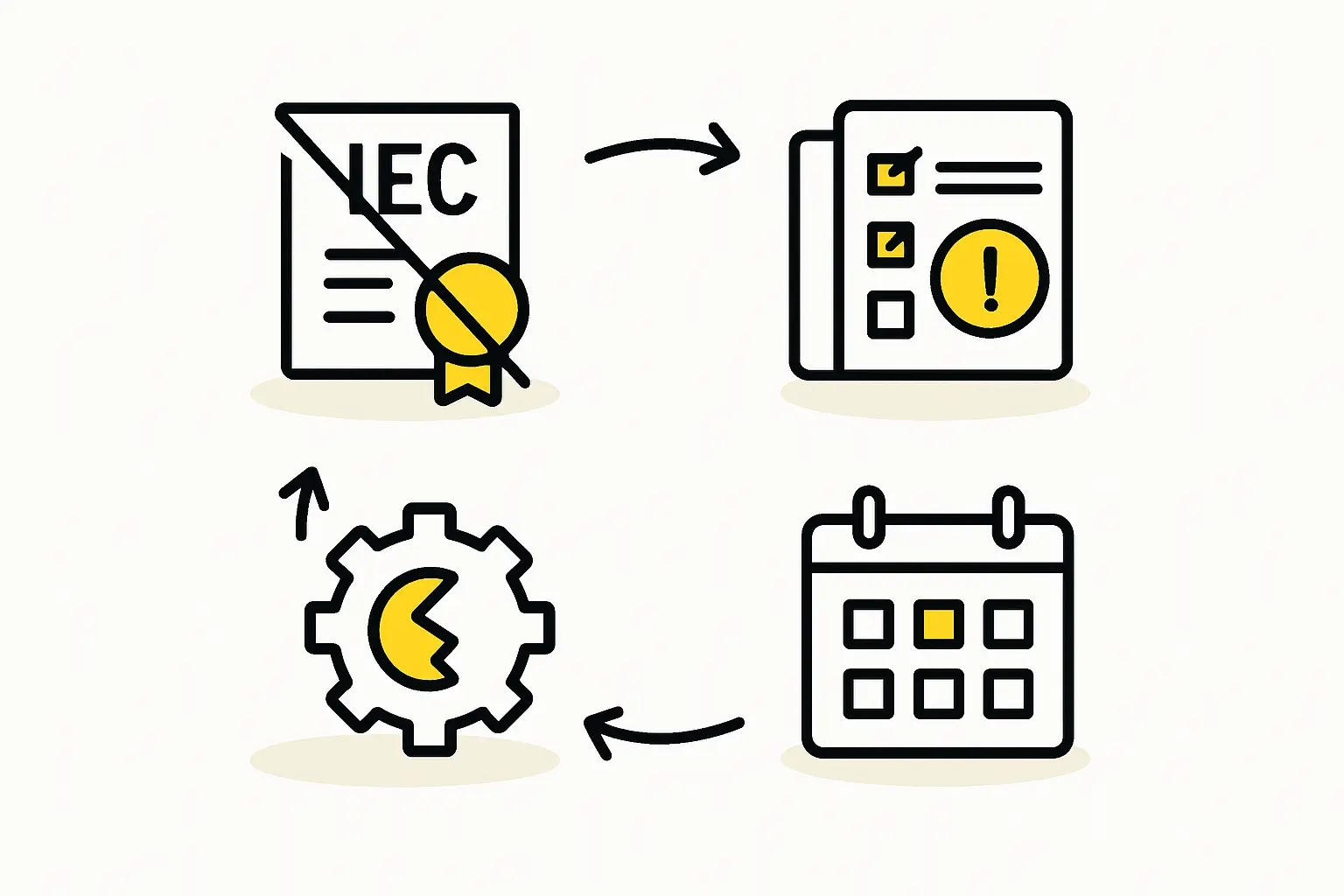

Step 4: Evaluation and Certification Decision

After testing is complete, the laboratory submits its report to KEBS. KEBS then reviews the entire file: the application, the factory audit report, and the lab test results.

If your products pass all tests and meet every requirement, KEBS will approve the certification. If non-conformities are found, you will be notified and given an opportunity to take corrective action. This could involve adjusting the production process, changing a component supplier, or improving quality control measures.

Step 5: Issuance of the Standardization Mark Permit

Upon successful evaluation, KEBS issues a permit allowing you to use the “Diamond Mark of Quality” on your certified solar modules. This permit is typically valid for one year and must be renewed. Renewal usually involves surveillance audits to ensure you maintain compliance.

Frequently Asked Questions (FAQ)

-

How long does the entire KEBS certification process take?

The timeline can range from three to nine months, depending on factors like the completeness of your initial application, the factory audit schedule, and the duration of laboratory testing. Proactive planning is key to minimizing delays. -

What are the typical costs involved?

Costs include application, factory audit, and laboratory testing fees. These can vary, so requesting a current fee schedule directly from KEBS is the best approach. These costs should be factored into the overall investment required for solar panel manufacturing. -

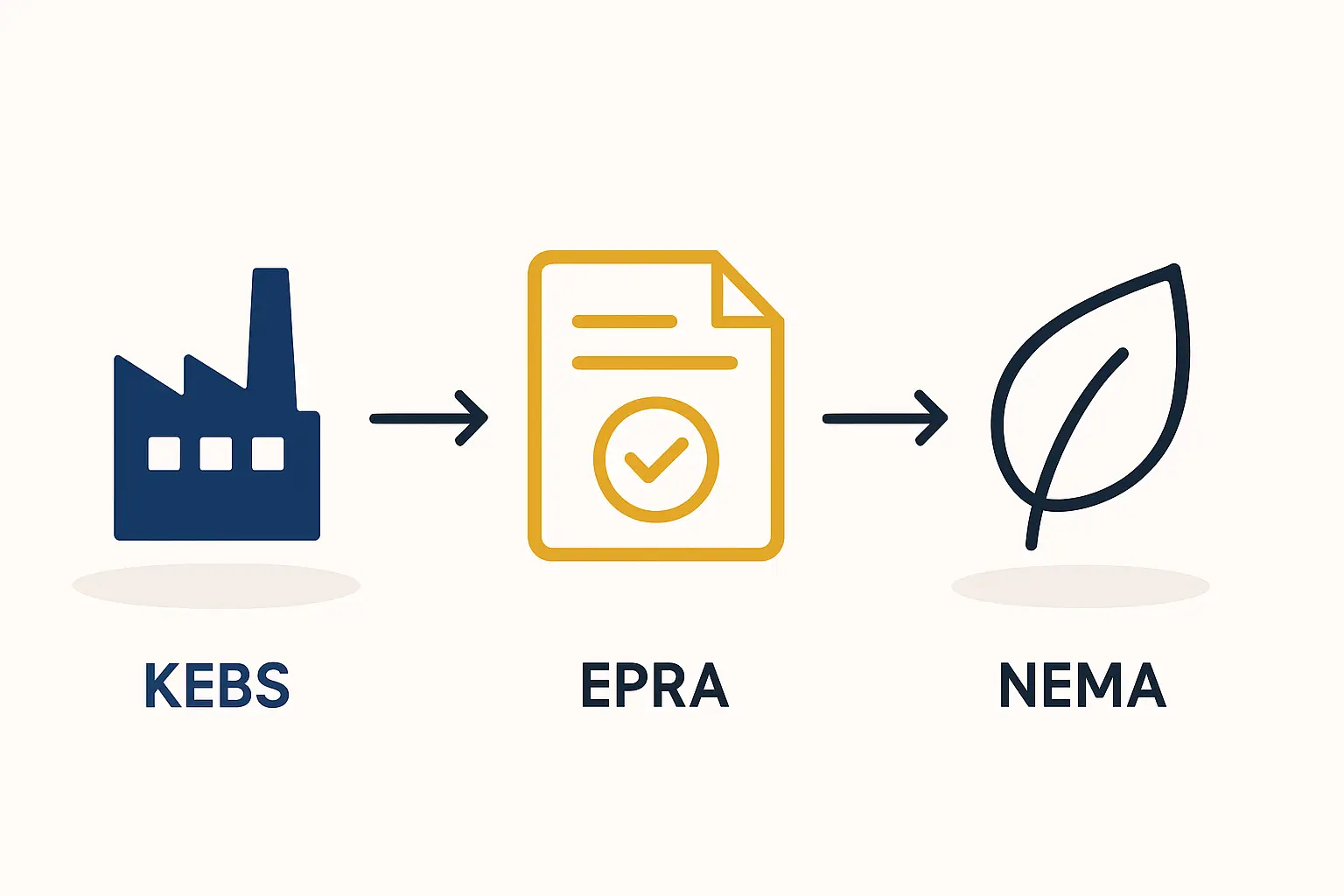

How does KEBS certification relate to EPRA licensing?

KEBS certification focuses on product quality and safety standards. The Energy & Petroleum Regulatory Authority (EPRA) handles the licensing of solar technicians, contractors, and energy producers. While distinct, both are part of the regulatory landscape for solar in Kenya. A manufacturer needs KEBS certification for its product, while an installer using that product needs an EPRA license. -

Can I use imported components in my locally assembled modules?

Yes. Most local assembly operations use imported solar cells, glass, and other components. However, you must be prepared to provide documentation and specifications for these items as part of your KEBS application, as their quality directly impacts the final product. -

What happens if my product fails the laboratory test?

If a module fails a test, you will receive a report detailing the non-conformity. You will then need to identify the root cause—be it a design flaw, a faulty component, or a process error—and implement corrective actions. After making the necessary changes, you may need to resubmit new samples for testing.

Planning for Success

Achieving KEBS certification is a methodical process that rewards preparation. By treating it as an integral part of your business strategy, rather than an administrative task, you position your venture for success in the Kenyan market. It is a testament to your commitment to quality and a prerequisite for building a sustainable and reputable manufacturing operation.

For entrepreneurs learning how to start a solar panel manufacturing business, understanding local compliance is as important as mastering the technology itself. With a clear roadmap and a focus on quality from day one, navigating the path to certification becomes a manageable and value-adding milestone.