An investor considering a solar factory in Libya faces two conflicting realities. On one hand, the country has some of the highest solar irradiation levels in the world—a vast, untapped resource for energy production. On the other, headlines often point to a challenging labor market, making the prospect of finding skilled technicians seem daunting.

A deeper analysis, however, reveals a significant opportunity. With a youth unemployment rate of over 50%, Libya has a large, available pool of young people eager for meaningful work. The challenge is not a shortage of people, but a shortage of specific, practical industrial skills.

For the discerning investor, this isn’t an insurmountable barrier. It’s a challenge that, with the right strategy, can become a source of competitive advantage. This article outlines a structured approach to sourcing, training, and developing a competent local workforce for a solar module manufacturing plant in Libya.

Understanding the Libyan Labor Market Landscape

Successfully building a local team begins with a clear-eyed view of the on-the-ground realities. While Libya has a high literacy rate of approximately 91% and universities that produce engineering graduates, it also faces specific systemic challenges.

-

The Practical Skills Gap: Many university engineering programs focus heavily on theory, with limited opportunities for hands-on application. Similarly, public vocational training centers are often underfunded, using outdated equipment that does not reflect the technology in a modern factory.

-

Emigration of Skilled Labor: Over the years, many experienced Libyan technicians and engineers have sought opportunities abroad, creating a ‘brain drain’ that has reduced the pool of senior technical talent within the country.

-

Public vs. Private Sector Employment: Traditionally, there has been a cultural preference for stable, public sector employment. However, a growing interest in renewable energy among younger Libyans signals a shift, creating an opening for private industrial projects to attract motivated individuals.

Despite these hurdles, the foundation is strong. The goal is to build a bridge between existing academic knowledge and the specific, repeatable skills required to operate, maintain, and manage a high-tech solar production line.

A Three-Pillar Strategy for Workforce Development

A successful workforce strategy does not rely on finding ‘perfect’ candidates. Instead, it focuses on creating them through a systematic process of recruitment, training, and long-term knowledge transfer.

Pillar 1: Strategic Recruitment and Talent Identification

The initial hiring process should prioritize aptitude and attitude over existing experience, which may be scarce.

-

Focus on Foundational Skills: Look for candidates from technical institutes and university engineering departments. Ideal candidates will have a solid grasp of basic electrical and mechanical principles, a logical approach to problem-solving, and a demonstrated desire to learn.

-

Collaboration with Institutions: Forge partnerships with local universities and vocational schools. This can create a direct pipeline of promising graduates and enable collaboration on curriculum adjustments that better serve industrial needs.

-

Assessment over Interviews: Move beyond traditional interviews by using practical assessments. Tasks like simple mechanical assembly or basic electrical circuit troubleshooting can reveal far more about a candidate’s innate technical ability and attention to detail.

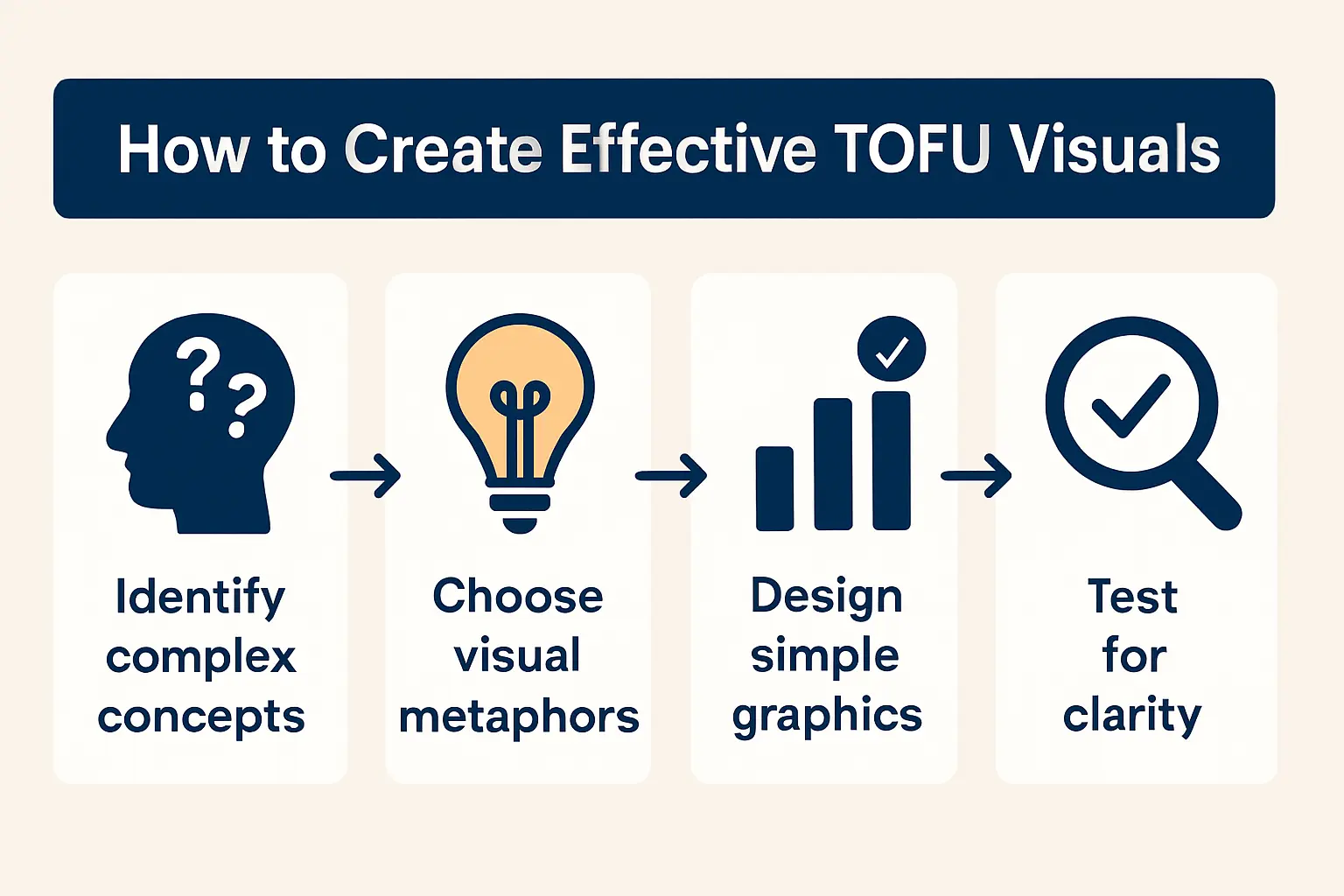

Pillar 2: Structured Training and Skill Development

Once a core team is recruited, a comprehensive training program is essential. This program must be designed to build skills from the ground up, assuming no prior experience in solar manufacturing.

The training regimen should be a blended model:

-

Classroom Theory: Begin with the fundamentals of photovoltaic technology, production processes, quality control standards, and workplace safety protocols.

-

Hands-On Machine Training: Under the direct supervision of experienced engineers (often from the equipment supplier), trainees learn to operate each piece of machinery. This starts with basic functions and gradually moves to more complex operations, calibration, and troubleshooting.

This phase emphasizes repetition and process discipline. The goal is to ensure each operator masters their station and understands how their work impacts the quality of the final product. Cross-training operators on several machines is key to developing a multi-skilled team and ensuring operational flexibility.

Pillar 3: Sustainable Knowledge Transfer and Retention

The final pillar ensures that the skills brought in by external experts are permanently embedded within the local organization.

-

The ‘Train the Trainer’ Model: From the initial group of trainees, identify individuals with leadership potential and strong communication skills. These individuals then receive advanced training to become local shift leaders and on-site trainers, capable of onboarding new employees in the future.

-

Standard Operating Procedures (SOPs): Develop clear, visual, and concise SOPs for every process. These documents, often in both English and Arabic, serve as definitive guides for consistent, high-quality production, reducing reliance on any single individual.

-

Cultivating a Professional Culture: Fostering a workplace culture based on quality, safety, and continuous improvement is critical for long-term success and employee retention. This helps transition the workforce from a public-sector mindset to a dynamic, results-oriented industrial environment.

The Role of an Experienced Technical Partner

For an entrepreneur or investor without a background in solar manufacturing, navigating this process alone presents significant risk. This is where an experienced turnkey technical partner becomes invaluable. A partner like J.v.G. Technology provides not just the machinery, but a comprehensive framework for building the human infrastructure around it.

This support is a critical component of starting a solar factory and directly impacts the long-term return on the initial investment for a solar factory. The training is specifically tailored to the solar panel manufacturing machines selected for the project and integrated into the overall solar factory layout.

Drawing on experience from turnkey projects in emerging markets, a partner’s role includes:

-

Defining job profiles and assisting in the recruitment process.

-

Executing the comprehensive training program, both in the classroom and on the factory floor.

-

Supervising the initial production ramp-up to ensure quality standards are met.

-

Implementing the ‘Train the Trainer’ model to ensure the factory’s self-sufficiency.

This structured guidance de-risks the project and accelerates the timeline from factory construction to profitable operation, ensuring the local team is competent and confident from day one.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale solar factory?

A typical semi-automated 20–50 MW production line requires approximately 25 to 30 production operators and technicians per shift. This includes roles for machine operation, quality control, logistics, and maintenance.

What are the most critical roles to fill first?

The first key hires should be a Plant Manager or Lead Engineer and a Quality Assurance Manager. These individuals will undergo the most intensive training and become the foundational pillars of the local management team.

Is it necessary to hire expatriate managers long-term?

The common strategy is to use expatriate experts for the initial setup, training, and ramp-up phases (typically 6–12 months). The primary goal is to make the local team fully autonomous, avoiding the high cost and dependency of long-term expatriate staff.

How long does it take to fully train a new team?

A comprehensive training program for a completely new workforce, from recruitment to confident independent operation, typically takes between 3 and 6 months. This timeline includes theoretical learning, hands-on practice, and a supervised production ramp-up period.

Conclusion: Transforming Potential into Production

The challenge of building a skilled technical workforce in Libya is real, but entirely manageable with a deliberate and structured strategy. By focusing on aptitude over experience, implementing a rigorous training program, and fostering a culture of quality, an investor can transform the country’s large youth population into a highly capable and motivated production team.

This approach not only ensures the operational success of the factory but also strengthens the local economy by creating stable, high-skilled industrial jobs. With the right plan and experienced guidance, a solar factory in Libya can successfully harness both the power of the sun and the potential of its people.