Imagine a newly commissioned solar module factory, a symbol of progress and energy independence. Production is running smoothly, and the first containers are ready for shipment.

Suddenly, meteorologists issue a severe cyclone warning. Within days, port operations are suspended, key roads become impassable, and the national grid fails. The factory, though physically intact, is operationally paralyzed.

This scenario is a predictable reality in many regions with high solar potential, such as Madagascar. For any entrepreneur planning to enter the solar manufacturing industry in a climate-vulnerable area, accounting for such disruptions is not an edge case—it’s a central pillar of a sound business strategy. This analysis explores the risks posed by cyclone seasons and outlines a framework for building a resilient manufacturing operation.

Understanding the Regional Climate Challenge: The Case of Madagascar

Madagascar serves as an excellent case study. The nation has an impressive average solar irradiation of nearly 2,800 kWh/m² per year, making it an ideal location for solar energy development. The government actively supports renewable energy and local manufacturing to improve energy access. This opportunity, however, is coupled with a significant, recurring climate risk.

The annual cyclone season, typically running from November to April, frequently brings Category 4 or 5 storms. The impacts are multifaceted:

- High Winds: Posing a direct threat to building structures and outdoor equipment.

- Storm Surges and Flooding: Endangering facilities in coastal or low-lying areas.

- Infrastructure Damage: Widespread power outages and damage to transportation networks are common, effectively isolating the facility.

For a manufacturing business, these events translate directly into operational and financial risk. Ignoring this annual weather cycle is akin to planning for failure.

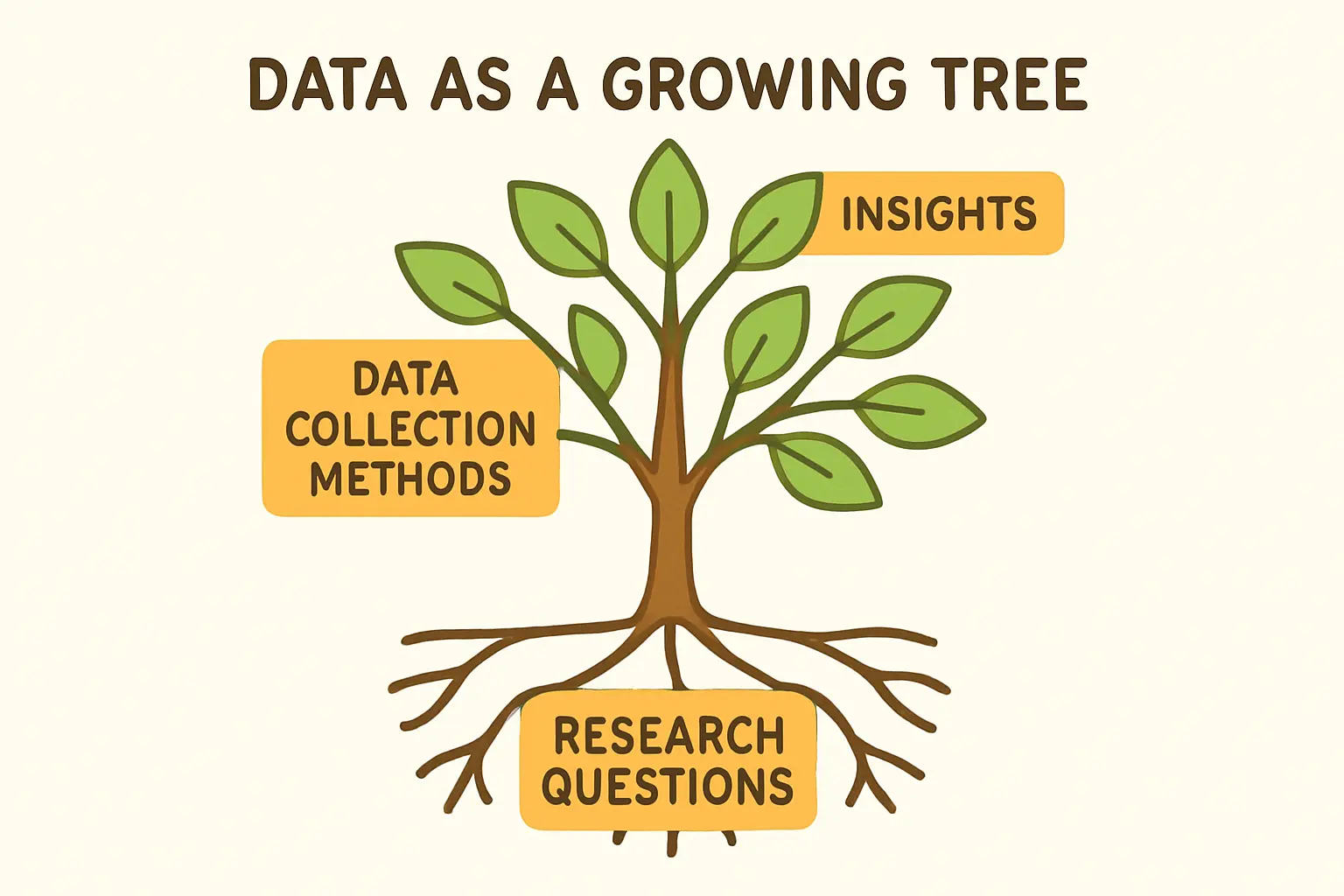

Core Areas of Vulnerability for a Solar Module Factory

A cyclone’s impact extends far beyond the factory walls. A comprehensive risk assessment must consider four key areas of vulnerability.

1. Infrastructure and Building Integrity

The physical plant is the most obvious asset at risk. Standard construction may not be enough to withstand the wind loads and torrential rains of a powerful cyclone. Foundations must be engineered to prevent water ingress, and the entire structure must adhere to stringent building codes. The structural integrity, roofing, and cladding, in particular, must satisfy the building requirements for a solar module factory in a high-risk zone. Failure here can lead to catastrophic equipment damage and extended downtime.

2. Supply Chain and Logistics

A modern factory relies on a continuous flow of materials in and finished products out. Cyclones sever these connections. Key ports like Toamasina may close for days or weeks, halting the import of essential components. A factory could quickly run out of the raw materials needed for solar panel manufacturing, such as solar glass, EVA encapsulant, and backsheets.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

At the same time, road washouts and bridge collapses can prevent finished modules from reaching domestic clients or export terminals, creating a bottleneck that halts revenue generation even if the factory itself is operational.

3. Energy and Operational Uptime

Madagascar, like many emerging markets, contends with an unreliable national grid. A major storm invariably compounds this problem, leading to prolonged blackouts. A solar module factory cannot function without a stable power supply, making reliance on the grid an untenable risk. A robust and independent backup power strategy, often combining diesel generators with an on-site solar-plus-storage system, is a prerequisite for operational continuity.

4. Workforce and Safety

The safety of employees is paramount. A business continuity plan must include clear protocols for safely suspending operations, securing the facility, and ensuring all staff can get home safely before a storm makes landfall. In the aftermath, transportation challenges may prevent staff from returning to work, causing further delays even after the immediate danger has passed.

Strategic Mitigation: From Planning to Implementation

Addressing these vulnerabilities requires a proactive, integrated approach that begins long before the first piece of equipment is ordered.

Proactive Site Selection and Construction

The first line of defense is choosing the right location. Whenever possible, select sites on higher ground, away from coastlines and floodplains. During the design phase, it is critical to partner with engineers who have specific experience with industrial construction in cyclone-prone regions. Based on experience from J.v.G. turnkey projects, investing more in a reinforced building envelope and advanced drainage systems at the outset is far more cost-effective than retrofitting or repairing a damaged facility.

Building a Resilient Supply Chain

Since logistical disruptions are inevitable, the solution lies in strategic inventory management. A resilient factory maintains a buffer stock of critical raw materials—enough to sustain production for several weeks or even months—before the cyclone season begins. This strategy transforms a potentially crippling external dependency into a manageable internal process. This ensures the solar panel manufacturing process can restart immediately once it is safe to do so, independent of port backlogs.

Developing a Business Continuity Plan (BCP)

A formal BCP is an essential management tool. This document should detail the step-by-step procedures for every phase of a potential disruption:

- Pre-Storm: Checklists for securing equipment, backing up data, and communicating with employees and suppliers.

- During Storm: Protocols for a skeleton crew, if any, and for monitoring the facility’s status.

- Post-Storm: Procedures for damage assessment, safety checks, and a phased restart of operations.

A well-documented BCP demonstrates foresight to investors and insurers and provides clarity and confidence to the management team during a crisis.

The Business Case for Climate Resilience

Investing in climate resilience is not merely an operational safeguard; it is a strategic advantage. A factory that can reliably produce and deliver modules, even in the face of regional disruptions, establishes itself as a dependable partner for national energy projects. It builds confidence among investors, may lead to more favorable insurance terms, and strengthens its long-term market position. In a world of increasing climate uncertainty, resilience is becoming synonymous with reliability and quality.

Frequently Asked Questions (FAQ)

How much does it cost to ‘cyclone-proof’ a factory?

It’s more effective to view this as an integrated design principle rather than an ‘add-on’ cost. While building to higher structural standards may increase initial construction costs, this investment is marginal compared to the potential losses from damage and business interruption. The focus should be on building correctly from the start.

Can a factory operate during the cyclone season?

Yes, but not during a direct cyclone impact. The strategy is not to defy nature but to minimize downtime. A well-prepared factory can operate normally during the season, execute a safe and orderly shutdown when a specific threat is imminent, and restart production quickly once the storm has passed and the facility is confirmed to be safe.

Does insurance cover all cyclone-related damages?

Insurance policies vary greatly and often have specific exclusions. A robust BCP and demonstrable risk mitigation efforts can lead to better coverage and more favorable premiums. However, insurance primarily covers asset loss; it rarely compensates fully for lost market opportunity and reputational damage caused by prolonged downtime.

Is this risk unique to island nations like Madagascar?

No. While the terminology changes—hurricanes in the Americas, typhoons in Asia—the fundamental risks of high winds, flooding, and supply chain disruption are globally relevant. The principles of resilient design, strategic inventory, and business continuity planning apply to any manufacturing operation in a region exposed to extreme weather events.