The Viability of a Small-Scale Solar Module Factory in Lebanon

Lebanon’s energy sector has navigated profound challenges with surprising resilience over the last few years. With the state utility, Electricité du Liban (EDL), providing power for just one to two hours daily, the country has turned to alternative solutions out of necessity. This shift has ignited an unexpected boom in the solar energy market, which surged from a modest 90 MW of installed capacity in 2020 to an estimated 1,000 MW by the end of 2023.

Yet, nearly every solar panel powering this transition is imported. This reliance raises a critical question for entrepreneurs and investors: amidst the economic uncertainty, is there a viable business case for establishing a local, small-scale solar module assembly line in Lebanon? This analysis explores the feasibility, requirements, and strategic advantages of such a venture, tailored to the nation’s unique market.

Understanding Lebanon’s Unique Energy Landscape

To evaluate the opportunity, one must first grasp the fundamental drivers of Lebanon’s solar adoption. This is not a market motivated by environmental policy, but by an urgent need for energy independence and economic survival.

The country’s de facto power grid is a patchwork of private diesel generators. This solution is not only unreliable but also prohibitively expensive, with electricity costing between USD 0.40 and 0.50 per kilowatt-hour. For businesses and households alike, this imposes a significant and unpredictable operational expense.

Solar power has emerged as the most practical and cost-effective alternative. The current market is defined by:

-

Dominance of Self-Consumption: The vast majority of installations are for residential homes and small-to-medium commercial and industrial (C&I) enterprises. These systems are designed to provide direct power and reduce reliance on both the failing state grid and expensive diesel fuel.

-

Absence of Large-Scale Projects: Due to political instability and the lack of clear government frameworks like net metering, large utility-scale solar farms have not materialized. Demand is decentralized and distributed.

This market structure is precisely why a small-scale production model is not just viable, but potentially more suitable than a large, inflexible gigafactory. The demand is for a consistent supply of modules for thousands of smaller projects, not massive shipments for a single solar park.

The Business Case for Local Solar Module Assembly

While importing modules from established hubs like China may seem like the default option, a local assembly operation presents several strategic advantages in a volatile environment like Lebanon’s.

The Challenge of Import Dependency

Relying solely on imports exposes businesses to several risks, each amplified by Lebanon’s economic crisis:

-

Supply Chain Volatility: Global shipping delays and logistical bottlenecks can stall projects and create uncertainty for installers.

-

Currency Fluctuation: Procuring goods in foreign currency while operating in a crisis-hit economy creates significant financial risk.

-

Lack of Customization: Importers are often limited to the standard module specifications offered by mass producers, which may not be optimal for every local application.

The Advantages of a Local Production Line

A domestic assembly plant can directly counter these challenges by offering:

-

Market Responsiveness: A local factory can adjust production based on real-time demand from installers, ensuring a steady supply and reducing lead times from months to days.

-

Logistical Simplicity: Local production removes the complexities and costs of international freight, customs clearance, and port handling for finished modules.

-

Economic Contribution: A ‘Made in Lebanon’ solar panel would carry powerful branding potential, representing a step towards industrial self-sufficiency and creating valuable local employment.

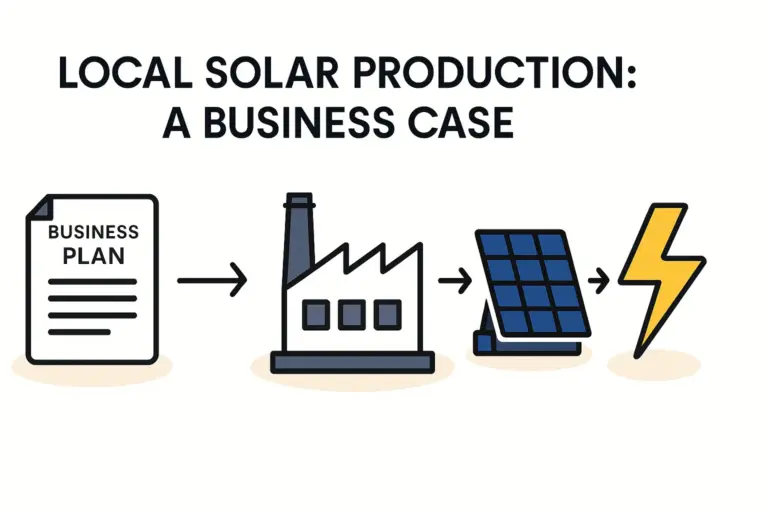

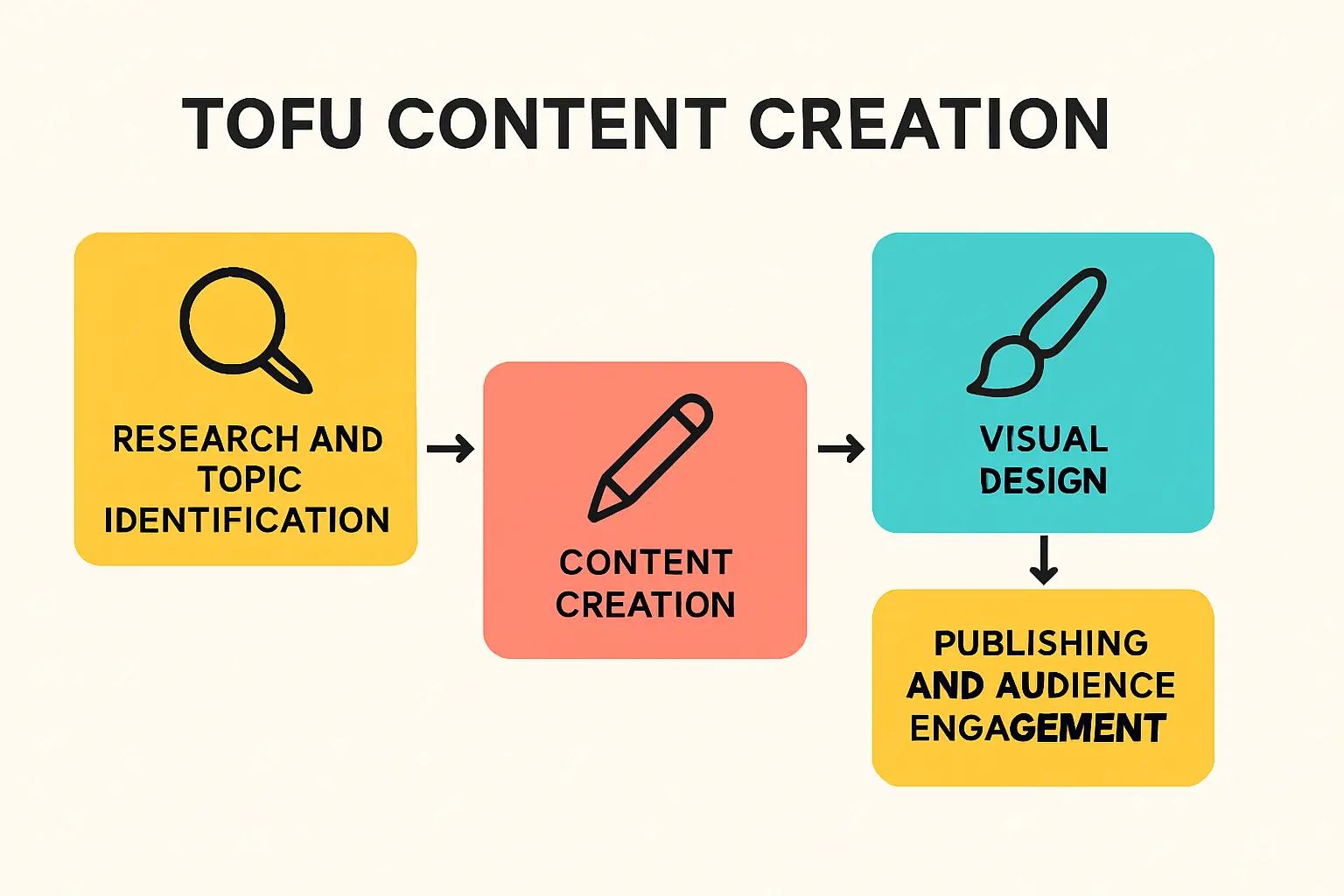

A Blueprint for a 25 MW Solar Factory in Lebanon

What does a ‘small-scale’ factory look like in practical terms? An annual capacity of 25 MW is an excellent entry point, balancing a manageable investment with meaningful output. Experience from J.v.G. turnkey projects shows that such a facility can be planned and commissioned efficiently.

Investment and Infrastructure Requirements

A semi-automated 25 MW assembly line requires a focused but not enormous capital outlay.

-

Machinery Investment: The core production equipment typically requires an investment of approximately USD 1.15 million. This covers essential stations like the stringer machine, laminator, and testing simulators.

-

Building Footprint: The entire production line can be housed in a facility of around 1,500 square meters, providing enough space for production, raw material warehousing, and finished goods storage.

Human Resources and Operations

A 25 MW line operates effectively with a team of around 27 employees, including operators, technicians, quality control personnel, and administrative staff. A detailed understanding of the required solar factory manpower is crucial for accurate financial planning and operational success.

From Plan to Production: A Realistic Timeline

With proper planning and execution support, an entrepreneur can move from initial concept to a fully operational production line in less than one year. As one client, Julius Etim, noted after establishing his factory in Nigeria, ‘We have been supported from A-Z… we started production within one year.’ This demonstrates that a structured, turnkey approach can dramatically accelerate the setup process.

Navigating the Challenges in the Lebanese Market

Building a successful enterprise in Lebanon requires a clear-eyed view of the obstacles and concrete strategies to mitigate them.

Financing and Economic Instability

The paralyzed local banking system means project financing will almost certainly have to come from external sources or private capital held abroad. The business plan must account for sourcing raw materials in USD while managing local currency revenues and expenses—a reality that demands a robust financial strategy.

Grid and Regulatory Hurdles

The lack of a functional grid and policies like net metering is a double-edged sword. While it stalls large-scale projects, it is the primary driver for the self-consumption market that a small-scale factory would serve. The immediate opportunity lies in providing modules for off-grid and hybrid solutions. Understanding the different types of solar panels suitable for these specific applications is key to meeting market demand.

Frequently Asked Questions for Aspiring Producers in Lebanon

- Is a 25 MW capacity large enough to be profitable?

Yes. In a market dominated by distributed generation, a 25 MW capacity is substantial. It can supply modules for 4,000 to 5,000 typical residential systems (5-6 kW) annually. Profitability in this model is driven by operational efficiency, consistent quality, and market availability, not sheer scale.

- Do we need highly specialized technical experts to run the factory?

While a few key leadership roles, like a production manager and lead technician, require experience, most operator positions can be filled by training local workers. A core component of a turnkey factory setup is knowledge transfer and establishing standardized operating procedures to ensure consistent output.

- How can a small factory compete with large Chinese manufacturers?

A local factory does not compete on head-to-head price for utility-scale tenders. Instead, it competes on factors more relevant to the Lebanese market:

-

Immediate Availability: No waiting for shipping containers.

-

Local Support and Service: Offering direct, accessible technical support.

-

Reduced Logistical Costs: Eliminating international freight and import duties on finished goods.

-

Customization: The ability to produce panel sizes or specifications tailored to local C&I needs.

This competition analysis is a vital part of the solar manufacturing business plan and must be tailored to these local market dynamics.

- What about obtaining the necessary raw materials?

Core components like solar cells, EVA encapsulant, glass, and backsheets are sourced from a global supply chain. A critical part of the initial setup involves establishing relationships with reliable international suppliers. A turnkey partner often helps establish these initial connections to ensure the supply chain is robust from day one.

Conclusion: The Opportunity for a First Mover

Despite Lebanon’s significant economic and political challenges, the country’s profound need for energy independence has created a tangible and growing market for solar solutions. The current landscape does not favor massive, capital-intensive gigafactories. Instead, it presents a compelling opportunity for an agile, responsive, and locally-focused small-scale module assembly plant.

For the right entrepreneur, this is a chance to be a first mover in a market with undeniable demand. By focusing on availability, local service, and quality, a Lebanese solar module factory can become a critical piece of the country’s energy solution and a profitable business venture. For investors considering this path, the next step is to develop a detailed financial model and technical plan tailored to this unique and promising environment.