An investor considering a new solar module factory in Bamako, Mali, typically focuses first on machinery, financing, and supply chains. However, a critical question frequently arises later in the process: ‘Where will we find the skilled workers to operate this advanced equipment?’ The perception of a scarce local workforce can seem like a significant obstacle.

The reality, however, is far more promising. Mali has one of the youngest populations in the world, with over 60% of its citizens under the age of 25. This demographic represents a vast, untapped reservoir of human potential.

The challenge is not a lack of people, but the absence of a structured pathway to transform motivated individuals into proficient technical operators. This guide outlines a strategy for building, not just finding, a world-class assembly team in Bamako.

Understanding the Bamako Labor Landscape

Building a successful workforce begins with understanding the local context. Bamako’s labor market presents unique opportunities and challenges that, when properly addressed, can become a significant competitive advantage.

The Demographic Dividend

The large youth population and significant unemployment rates create a vast and eager pool of candidates. This demographic is a key asset for a new industrial enterprise like a solar module factory. These young people are often seeking stable, long-term employment and are highly receptive to acquiring valuable technical skills.

Educational and Skill Baseline

While Mali’s primary education enrollment is high, the adult literacy rate hovers around 35-40%. This means purely text-based training methods are likely to be ineffective.

However, the region has a strong tradition of artisanal skills. Many young people have excellent manual dexterity and practical problem-solving abilities learned in fields like electronics repair, tailoring, or metalworking. This aptitude for hands-on work is an ideal foundation for the precision tasks required in solar module assembly.

The key is to shift the focus from seeking prior qualifications to identifying raw potential.

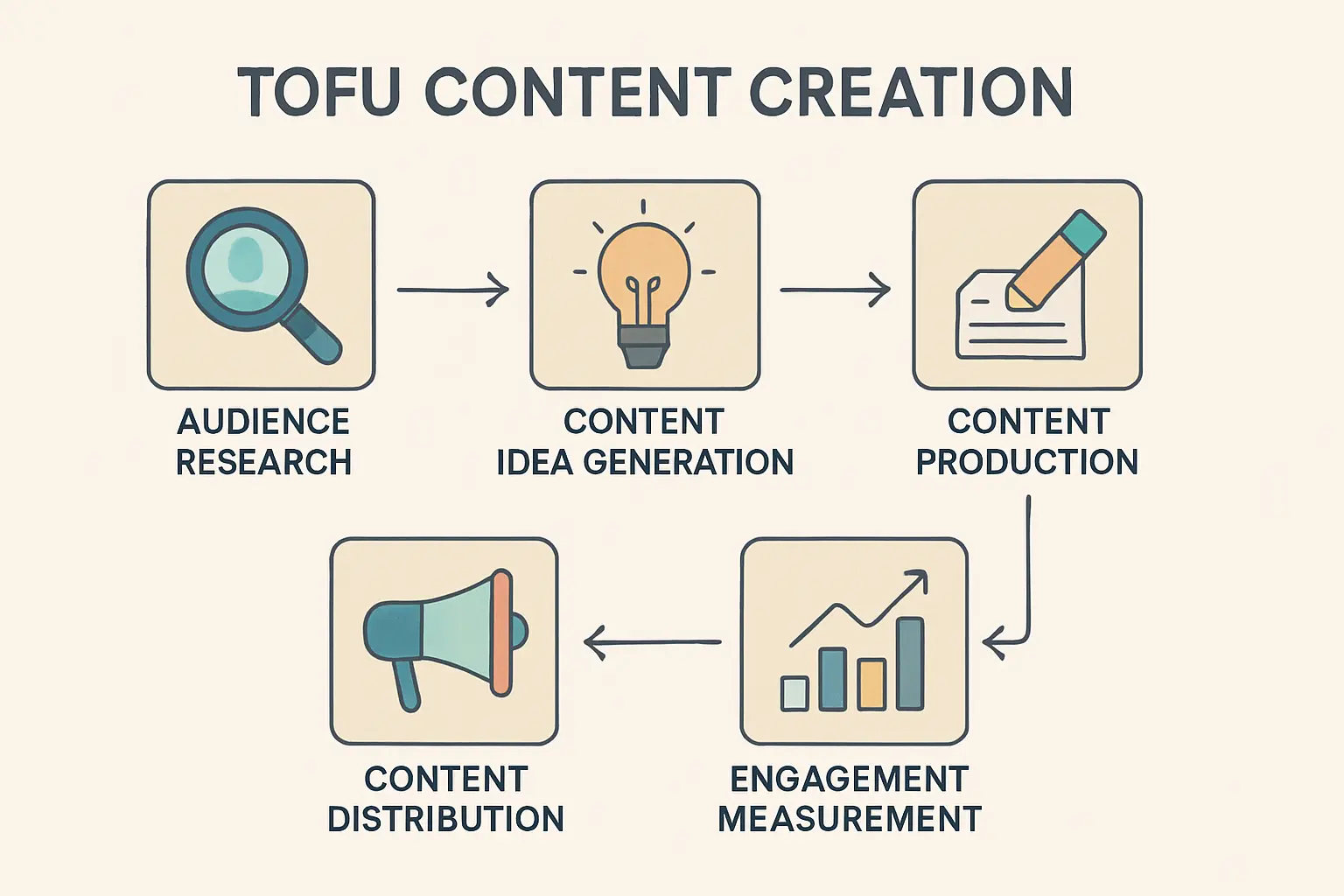

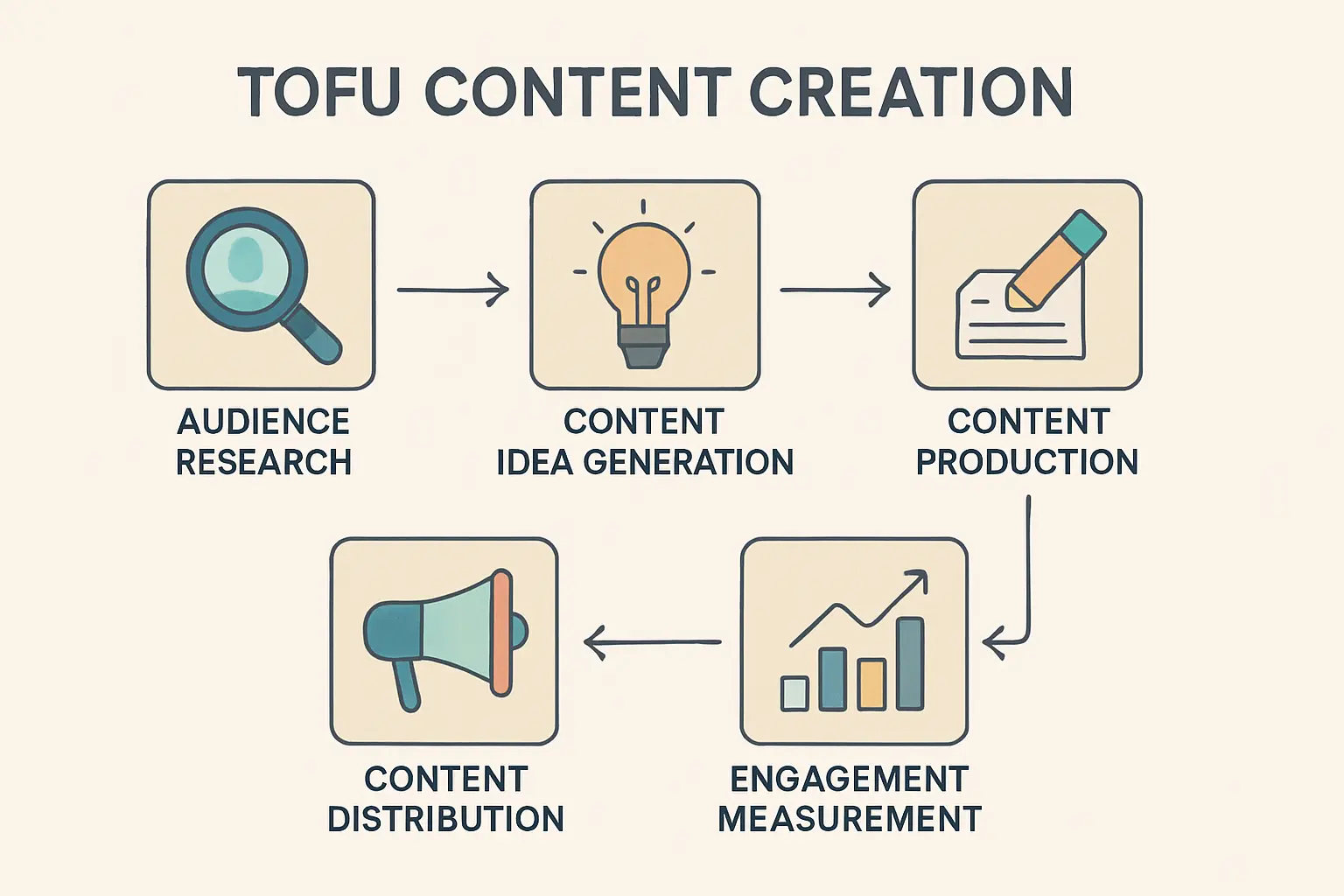

A Three-Phase Approach to Workforce Development

Transforming this potential into a high-performing production team requires a systematic approach. Experience from J.v.G. turnkey projects shows that a three-phase process of recruitment, training, and retention proves most effective.

Phase 1: Strategic Recruitment

The goal is not to find candidates who have already worked in solar manufacturing, as they are unlikely to exist locally. Instead, recruitment should focus on identifying individuals with the right aptitudes.

Key Attributes to Screen For:

-

Attention to Detail: The ability to handle delicate components like solar cells without causing micro-cracks is crucial.

-

Patience and Focus: Module assembly involves repetitive tasks that demand consistent concentration.

-

Hand-Eye Coordination: Candidates with backgrounds in crafts or detailed repair work often excel.

-

Basic Numeracy: The ability to understand basic measurements and production targets is essential.

Recruitment efforts can be targeted at vocational training centers, community workshops, and artisanal guilds, where individuals with these foundational skills can be found.

Phase 2: Tailored, Hands-On Technical Training

Once the right candidates are selected, a customized training program is the most critical investment. The program must bridge the gap between general aptitude and the specific requirements of operating a modern production line.

Effective training goes beyond theory. It should be overwhelmingly practical, visual, and supervised. A typical curriculum would break down each stage of the manufacturing process:

-

Cell Handling and Stringing: Trainees learn the delicate process of handling solar cells and using a stringer machine to solder them into rows. This stage emphasizes precision and the cost of breakages.

-

Layup and Bussing: Operators are trained to assemble the layers of the module—glass, EVA, cells, and backsheet—in the correct sequence and connect the strings.

-

Lamination and Curing: This involves learning to operate the laminator, a key piece of equipment, and understanding the temperature and pressure profiles required for a durable module.

-

Framing and Junction Box Installation: The final assembly steps, requiring accuracy to ensure the module is robust and weatherproof.

Given the local literacy levels, training materials should rely heavily on diagrams, demonstrations, and hands-on practice with the actual solar panel manufacturing machines. An experienced external supervisor, provided as part of a turnkey solution, is invaluable during this initial phase to establish best practices and a culture of quality.

Phase 3: Retention and a Professional Work Environment

Recruiting and training a skilled team is only half the battle; retaining them is essential for long-term success and profitability. High employee turnover increases training costs and disrupts production consistency.

Retention is built on a professional, safe, and motivating work environment.

Key Pillars of Retention:

-

Fair Compensation: Offering competitive wages makes the factory a desirable employer.

-

Safety and Cleanliness: A well-organized and safe factory floor demonstrates respect for the workforce and is essential for efficient production.

-

Clear Career Paths: Providing opportunities for advancement—from operator to team leader, quality inspector, or maintenance technician—gives employees a long-term vision within the company.

Creating this environment transforms a job into a career, ensuring that the initial investment in training delivers returns for years to come.

From Assembly Line to Operational Excellence

A well-trained and motivated workforce is the engine that drives a factory’s success. It directly impacts production volume, defect rates, and the ability to meet international quality control standards. A team that understands the ‘why’ behind their tasks—not just the ‘how’—is better equipped to identify potential issues before they become costly problems.

This human element is critical to a turnkey solar module production line. The machinery provides the capacity, but the people unlock the potential. Proper investment in human capital ensures the entire operation, from factory layout and planning to final product testing, functions as a cohesive and efficient system.

Frequently Asked Questions (FAQ)

Do I need to hire workers with prior solar industry experience?

No. In a market like Bamako, it’s more effective to hire for aptitude and train for skill. Look for individuals with strong manual dexterity, attention to detail, and a willingness to learn. A structured, hands-on training program is designed to build the necessary expertise from the ground up.

How long does it take to train a new machine operator?

For a motivated individual with the right aptitude, basic proficiency on a specific machine (like a stringer or laminator) can be achieved within four to eight weeks of intensive, supervised training. Becoming a highly efficient operator with deep troubleshooting skills may take several months.

What is the typical team size for a small-scale solar factory?

A semi-automated 20–50 MW production line typically requires a workforce of 25 to 35 employees. This includes production operators, supervisors, quality control staff, maintenance technicians, and a small administrative team.

How does factory layout and planning impact workforce efficiency?

A logical factory layout and planning process is crucial. It minimizes material movement, reduces physical strain on operators, and creates a clear, streamlined workflow. This not only increases output but also contributes to a safer and more organized work environment, which helps retain skilled staff.

The Human Capital Advantage

The challenge of building a solar module assembly factory in Bamako is not a shortage of labor, but an opportunity to cultivate it. Mali’s young, ambitious population represents a strategic asset for any investor willing to implement a structured approach to recruitment, training, and professional development.

By focusing on building local talent, a new enterprise can create a loyal, highly skilled workforce that becomes a sustainable competitive advantage. This journey—from a skilled individual to a high-performing team—is essential to building a successful and lasting solar manufacturing business in Mali.