Mauritius is often recognized for its stunning landscapes and robust tourism sector. For the discerning entrepreneur, however, its true potential may lie in its stable economy, strategic location, and educated workforce. With a government actively promoting renewable energy and a history of manufacturing excellence, the island presents a compelling case for establishing a solar module production facility. The critical question, however, is not simply one of potential, but of people: does the local labor market have the skills for a high-tech solar assembly line, and what would it take to bridge any existing gaps?

This analysis explores the practical considerations of building a skilled workforce in Mauritius for a solar panel factory. It examines the existing talent pool, typical wage structures, and the training programs needed to turn general manufacturing experience into specialized photovoltaic expertise.

The Foundation: Analyzing Mauritius’s Existing Workforce

An investor’s first step is to assess the available raw materials—and in manufacturing, the most valuable of these is human capital. Mauritius offers a strong starting point, backed by several key advantages that de-risk the initial investment in labor.

Key Strengths of the Mauritian Labor Pool

Based on economic data and on-the-ground project experience, several factors make the Mauritian workforce well-suited for industrial projects:

-

High Literacy and Education: With a literacy rate exceeding 90%, the population has a strong educational foundation. This is critical for absorbing technical training materials and adhering to complex quality control protocols.

-

Bilingual Proficiency: Widespread proficiency in both English and French is a significant asset for international operations, simplifying communication with foreign equipment suppliers, trainers, and potential export markets.

-

Existing Manufacturing Experience: The country has a well-established manufacturing sector, particularly in textiles and electronics. Workers from these industries are already familiar with production line discipline, shift work, and the importance of meeting output targets—a valuable and transferable skill set.

-

Economic and Political Stability: As one of Africa’s most stable and business-friendly environments, Mauritius provides a predictable landscape for long-term workforce planning and investment. Government support for renewable energy projects further enhances this stability.

Understanding Local Wage Structures

Labor costs are a primary consideration in any business plan. In Mauritius, wages for semi-skilled and skilled factory workers are globally competitive. Recent industry analysis shows that while entry-level wages for production line operators fall within a predictable range, salaries for technicians and supervisors are higher, reflecting their advanced skills and responsibilities. This structure allows for clear financial forecasting and a sustainable compensation model that can attract and retain talent. A detailed breakdown of these costs is a core component of a thorough business plan for a solar factory.

From General Skill to Specialized Expertise: The Training Imperative

While the Mauritian workforce has a solid industrial foundation, producing high-quality solar modules requires specialized skills that are not yet widely available. The transition from a textile factory floor to a sterile, high-precision solar assembly line is significant. A structured training program is therefore the most critical investment in the factory’s long-term success.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

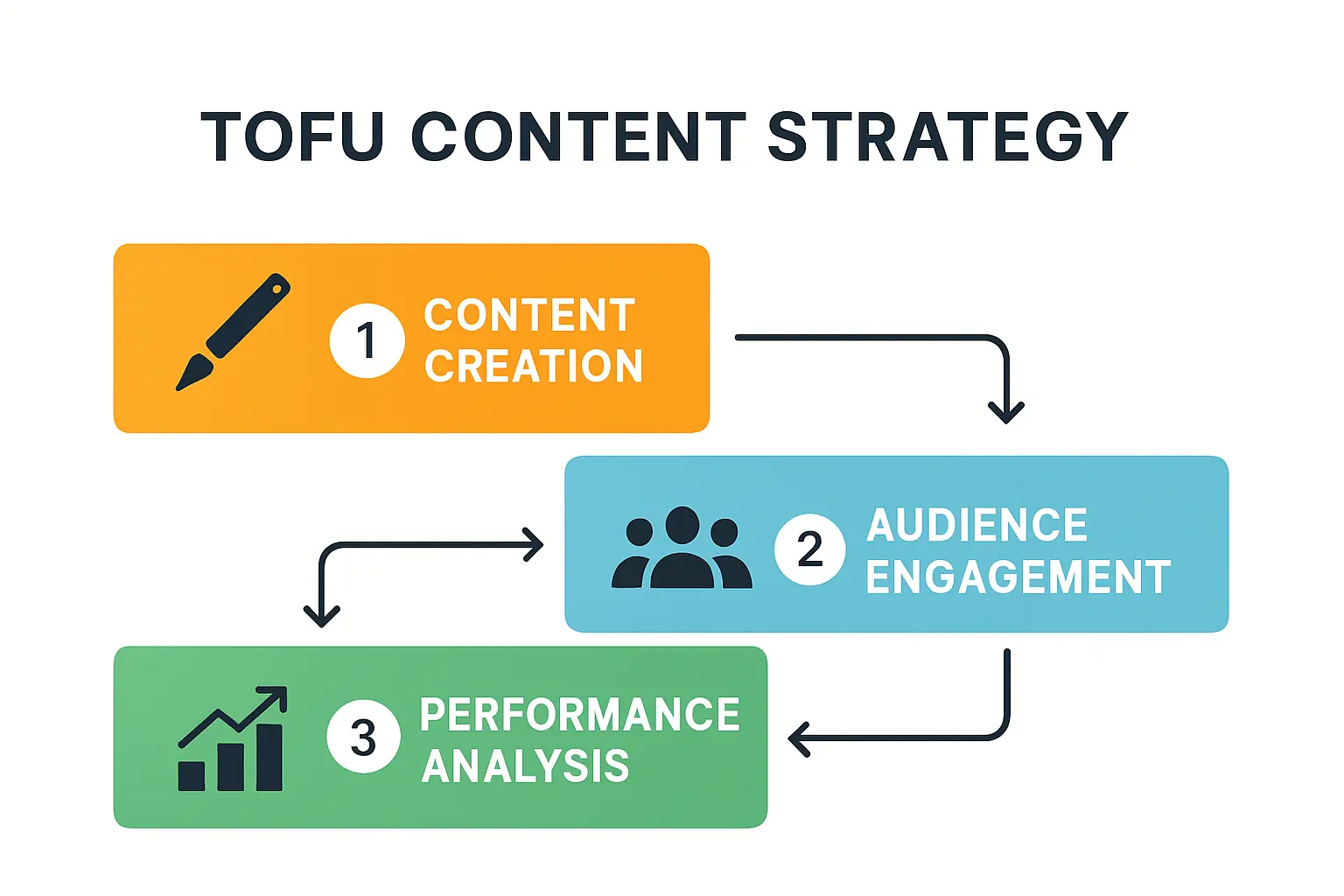

Core Competencies for a Solar Production Line

A typical semi-automated solar production line requires personnel trained in three key areas:

-

Machine Operation: This involves more than simply pressing buttons. Operators for machines like stringers, laminators, and testers must understand the technical processes, perform basic troubleshooting, and recognize deviations from quality standards. Their precision directly impacts module efficiency and longevity.

-

Quality Control (QC): QC technicians are responsible for visual inspections, electroluminescence (EL) testing, and performance analysis using sun simulators. As the guardians of product quality, they must be trained to identify subtle defects that could lead to field failures.

-

Maintenance and Engineering: A small team of technicians handles routine maintenance, calibrates machinery, and addresses technical issues. Their expertise ensures minimal downtime and consistent production quality—both fundamental to any turnkey solar production line.

A Phased Approach to Workforce Development

Experience from J.v.G. Technology GmbH projects in emerging markets shows that a two-phase training approach is highly effective.

-

Phase 1: Classroom and Theoretical Training: Before hands-on work begins, the initial team undergoes intensive classroom training. This covers the fundamentals of photovoltaic technology, safety protocols, material handling, and the specific function of each machine in the production sequence.

-

Phase 2: On-the-Job Supervision: Once the production line is installed, experienced engineers and process specialists—often provided by the turnkey supplier—work alongside the new employees. This hands-on mentorship is crucial for translating theoretical knowledge into practical skill, ensuring the team can operate the line independently and efficiently within a few months.

This structured approach minimizes the learning curve and builds a self-sufficient, confident local team capable of running the factory to international standards. The initial labor requirements for a solar factory are manageable, often starting with fewer than 30 employees for a 20-50 MW line.

Frequently Asked Questions (FAQ)

What are the typical monthly wages for a factory worker in Mauritius?

While this varies by skill and experience, an entry-level production operator can expect a salary in line with the national average for the manufacturing sector. A detailed financial model would budget approximately MUR 15,000–25,000 for operators, with higher figures for skilled technicians and supervisors.

Is it necessary to hire foreign experts to run the factory?

Initially, standard practice is to have one to three expatriate experts on-site for the first 6-12 months. Their role is not to run the factory long-term but to train the local management, engineers, and supervisors. The goal is a complete knowledge transfer, enabling the local team to manage all operations independently.

How long does it take to train a new team for a solar production line?

With a structured, two-phased training program, a newly hired team with general manufacturing experience can typically reach operational proficiency within three to six months. This timeline includes classroom instruction and the crucial on-the-job training period after the equipment is installed.

Does the Mauritian government provide support for training in the renewable energy sector?

Yes, the government of Mauritius, through agencies like the Human Resource Development Council (HRDC), often provides incentives and support schemes for training and upskilling the workforce, particularly in priority sectors like renewable energy and green technology.

Conclusion: Strategic Investment in People is Key to Success

The Mauritian labor market offers fertile ground for establishing a solar module manufacturing facility. The combination of a strong educational base, existing industrial experience, and a stable business environment significantly lowers the barrier to entry.

However, the potential of this workforce can only be unlocked through a deliberate, strategic investment in specialized training. Success isn’t just about sourcing machinery; it’s about cultivating the human expertise required to operate it at maximum efficiency. By implementing a comprehensive training program, an investor can build a world-class local team, ensuring the long-term quality, efficiency, and profitability of the operation. For entrepreneurs exploring this venture, understanding how to start a solar panel factory begins with a clear strategy for its most important asset: its people.