Imagine walking the docks at the Monaco Yacht Show. You’re surrounded by symbols of peak engineering and design—from the polished hulls of superyachts to the precision timepieces on the wrists of their owners.

Now, look closer at the vast, sun-drenched surfaces of these vessels. Here lies a significant, often overlooked opportunity: integrating high-performance solar technology that meets the exacting standards of the luxury world.

This isn’t about standard, mass-produced solar panels. It’s about creating a new category of energy solutions where performance is matched by aesthetics and prestige. For an entrepreneur in the solar industry, a location’s unique brand identity can be a powerful market differentiator. This article explores the strategic case for establishing a ‘Made in Monaco’ solar brand, tailored specifically for the global luxury and marine markets.

The Power of Provenance: Why Brand Location Matters

In the world of luxury goods, a product’s origin, or provenance, is fundamental to its value. ‘Swiss Made’ conveys precision engineering in watchmaking, while ‘Italian Made’ suggests superior craftsmanship in fashion and automotive design.

The ‘Made in Monaco’ label carries a similar weight, evoking a world of exclusivity, high finance, and technological sophistication, symbolized by events like the Grand Prix and the world-renowned Yacht Show. By establishing a solar manufacturing presence in Monaco, a brand can instantly align with these qualities. This strategic positioning shifts the perception of a solar module from a simple industrial commodity to a piece of high-end technology.

This association becomes the foundation for a business model built not on volume, but on value. Understanding how brand positioning can define your target market and pricing power is a critical first step when evaluating how to start a solar panel manufacturing business.

Identifying the Niche: Targeting High-Value Sectors

A premium brand requires a premium market. A Monaco-based solar enterprise would not compete with large-scale manufacturers. Instead, it would focus on specialized sectors where price is secondary to performance, aesthetics, and customization.

The Superyacht and Marine Industry

The global superyacht market is projected to reach $13.26 billion by 2032, driven by a growing demand for larger, more technologically advanced, and sustainable vessels. Yacht owners and designers demand energy solutions that are efficient, durable, and seamlessly integrated into a vessel’s design.

Key requirements for this sector include:

- High Power Density: Maximum energy generation from limited deck or roof space.

- Durability: Resistance to corrosive salt-mist, high winds, and the harsh marine environment.

- Aesthetics: Low-profile, flexible, or custom-colored modules that complement the yacht’s lines rather than detract from them.

Bespoke Architecture and Luxury Real Estate

High-net-worth individuals and developers are increasingly incorporating sustainable technologies into luxury properties. However, standard solar panels often conflict with the architectural vision. This creates a demand for Building Integrated Photovoltaics (BIPV), where solar cells become part of the building’s structure—in facades, skylights, or roofing materials.

A ‘Made in Monaco’ brand is perfectly positioned to serve this market, offering custom-designed solar solutions that function as both a power source and a premium architectural feature.

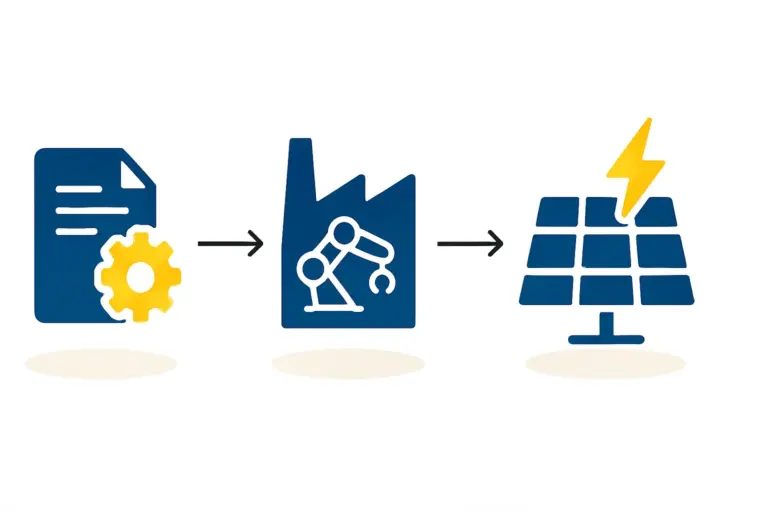

Developing the Product: Beyond Standard Solar Modules

Serving these niche markets requires a product that is fundamentally different from the modules produced in a standard gigawatt factory. The focus shifts from cost reduction to value creation through superior technology and craftsmanship.

Technical Excellence and Customization

Product strategy must prioritize cutting-edge technology and bespoke features. The solar panel manufacturing process for such modules more closely resembles that of a specialized workshop than a mass-production line.

- High-Efficiency Cells: Utilizing advanced cell technologies like TOPCon or HJT is essential to maximize energy output in space-constrained applications.

- Custom Aesthetics: Offering modules in custom colors, sizes, and finishes, including frameless designs that blend into architectural surfaces.

- Enhanced Durability: Engineering modules to withstand extreme conditions, such as the high wind loads and vibrations experienced at sea.

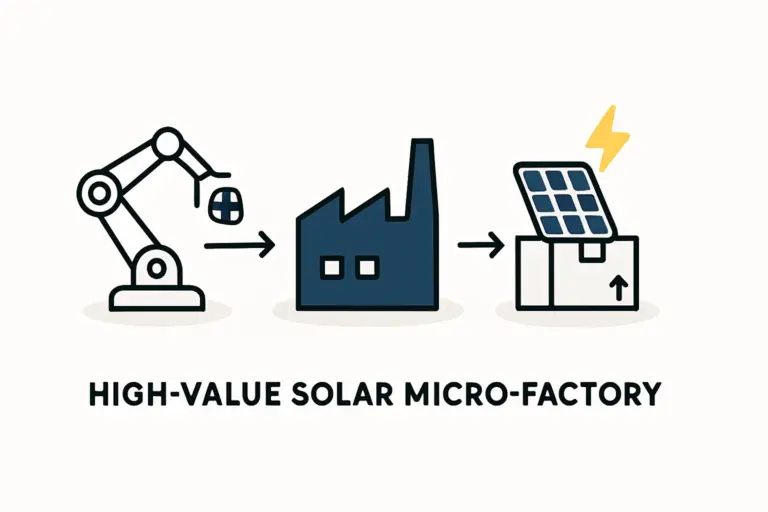

The ‘Atelier’ Manufacturing Approach

The high operating costs associated with Monaco, particularly for real estate and labor, make a traditional, large-scale manufacturing model unfeasible. The strategic response is to adopt an ‘atelier’ or ’boutique’ model.

This involves a smaller, highly skilled team focused on low-volume, high-customization assembly. This approach turns a potential disadvantage—high costs—into a core part of the brand story, justifying a premium price through craftsmanship and exclusivity.

The Business Case: Strategy, Costs, and Logistics

While the brand prestige is clear, a successful venture depends on a sound business model that addresses both opportunities and challenges.

Strategic Advantages:

- Proximity to Market: A Monaco base provides direct access to the superyacht industry, designers, architects, and a global network of high-net-worth individuals.

- Logistical Hub: Its central Mediterranean location offers excellent logistics for exporting to key markets in the Middle East, North America, and across Europe.

- Favorable Environment: The principality offers political stability and a pro-business framework that welcomes new enterprises.

Investment and Costs:

The solar panel manufacturing plant cost for a boutique operation is structured differently from that of a large-scale factory. Investment focuses on specialized, flexible assembly equipment and skilled technicians rather than high-speed, automated lines.

Based on experience from turnkey projects, a small-scale line of 10-20 MW can be established with a manageable footprint and workforce, aligning with the atelier model. The business plan must account for higher operational expenditures, which are offset by the high margins on each custom-built unit.

Frequently Asked Questions (FAQ)

Is Monaco a practical location for any type of manufacturing?

No. Monaco’s high operational costs make it suitable only for high-value, low-volume manufacturing where brand prestige is a key part of the product’s value. This makes it unsuitable for commodity production.

What is the primary difference between a luxury solar module and a standard one?

The key differences lie in four areas: customization (size, shape, color), materials (higher-grade, more durable components), efficiency (using the most advanced cell technology), and design integration (the ability to become a seamless part of a yacht or building).

How large would a ’boutique’ solar factory need to be?

A boutique facility would be significantly smaller than a conventional plant. A production line with an annual capacity of 10-20 MW, focused on specialized assembly, could operate effectively in a space of 1,500–2,500 square meters with fewer than 30 employees.

Is this luxury market large enough to be profitable?

While the total number of units is smaller than in the mass market, profitability is driven by extremely high margins per unit. The model targets a specific, affluent customer base willing to pay a significant premium for a product that meets their unique demands for performance, aesthetics, and brand alignment.

The ‘Made in Monaco’ concept is a sophisticated business strategy. It exemplifies how entrepreneurs can enter the competitive solar industry by creating a new market category rather than competing in an existing one. By aligning product, brand, and target market, it transforms a solar module from a utility product into a luxury asset, opening up a unique and profitable niche in the global market.