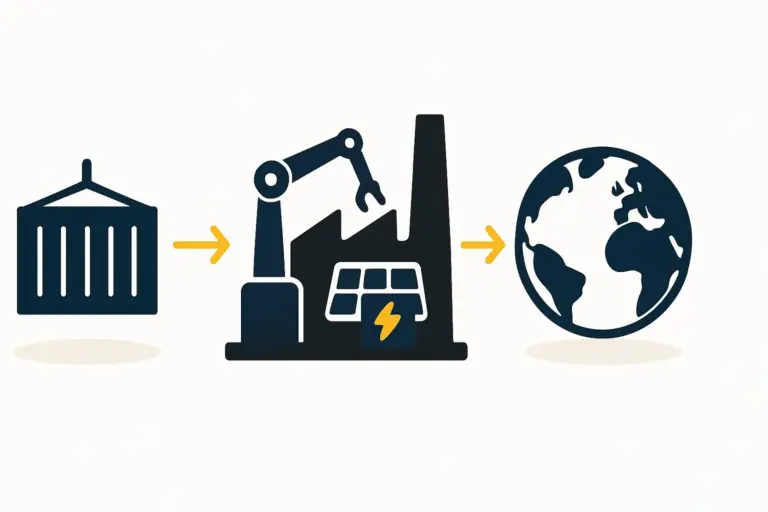

Consider a common scene in Moldova: a vineyard owner inspects his grapes under the intense summer sun, worried about rising irrigation costs and the potential for crop damage from heat stress.

Now, imagine that same vineyard with rows of specialized solar panels elevated above the vines. These panels not only protect the crops from harsh weather but also generate electricity to power the farm’s irrigation pumps, reduce water evaporation from the soil, and create a new revenue stream from selling surplus energy.

This scenario is not a distant vision but the practical application of agrivoltaics (APV), a technology that opens up a significant business opportunity for entrepreneurs in Moldova. With an agricultural sector forming 12% of its GDP and a heavy reliance on imported energy (over 70%), a venture focused on producing specialized solar modules for domestic farms would tackle two of the country’s most pressing strategic challenges. This article explores the business case and technical requirements for establishing such a manufacturing facility.

The Intersection of Agriculture and Energy: What is Agrivoltaics?

Agrivoltaics is the practice of using the same parcel of land for both solar power generation and agricultural production. Unlike a conventional ground-mounted solar farm that occupies land exclusively, an APV system is designed to create a symbiotic relationship between the two. The solar panels are typically mounted on taller structures, allowing enough space for crops to grow and for farm machinery to operate underneath.

The primary goal is to optimize land use, creating two distinct yields—crops and energy—from a single area. For a country like Moldova, where agriculture is a cornerstone of the economy and increasingly vulnerable to drought, the benefits are particularly compelling:

- Improved Crop Health and Yield: The partial shade from the panels can protect sensitive crops from scorching sun and hail, reducing heat stress and improving quality.

- Water Conservation: Reduced sun exposure lowers soil temperature and decreases water evaporation, a critical advantage in managing irrigation resources.

- On-Farm Energy Independence: Generated electricity can power farm operations, such as irrigation systems, cooling facilities, and processing equipment, shielding farmers from volatile energy prices.

- Diversified Revenue: Farmers gain a stable, long-term income source from selling electricity to the grid, supplementing often-unpredictable agricultural revenues.

This dual-use approach directly supports Moldova’s national goal of having renewables cover 30% of energy consumption by 2030 while strengthening its most vital economic sector.

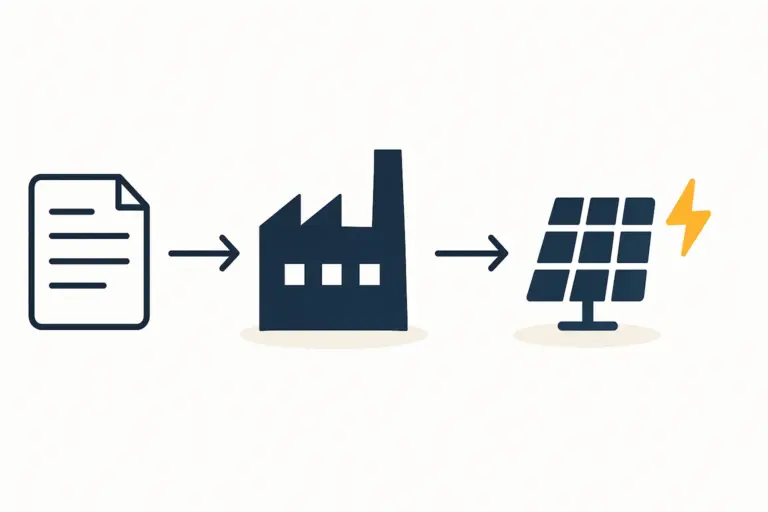

Why Standard Solar Modules Are Not Sufficient for Agrivoltaics

An entrepreneur might reasonably ask why a new type of module is needed when standard solar panels are widely available. The answer lies in the unique requirements of a shared-use environment. Conventional solar modules are designed for maximum power output, meaning they are fully opaque and block nearly all sunlight from reaching the ground beneath them. This is ideal for a dedicated solar farm but unsuitable for growing most crops.

Successful agrivoltaics requires modules specifically engineered to balance the needs of plants with the demands of energy generation. This specialization is precisely where the manufacturing opportunity lies.

Key Technical Specifications for Agrivoltaic Modules

Producing modules for APV applications involves specific design considerations that differ from standard manufacturing.

- Controlled Light Transmission: APV modules must be semi-transparent to allow a calculated amount of sunlight to reach the crops. This is often achieved by increasing the spacing between the solar cells within the module, creating transparent gaps. The level of transparency can be customized depending on the light requirements of the specific crop, whether it’s grapes, sunflowers, or vegetables.

- Bifacial Technology: High-performance APV modules are typically bifacial, meaning they can capture sunlight on both sides. The front side absorbs direct sunlight, while the rear side absorbs light reflected from the ground and the crops themselves. This can increase the total energy yield by 10-25% compared to a monofacial module, making the system far more efficient.

- Enhanced Durability: An agricultural environment is more demanding than a typical solar field. Modules must be robust enough to withstand dust, moisture, and potential impacts from farm equipment. A glass-glass construction, where solar cells are sandwiched between two layers of glass, offers superior durability and a longer lifespan than the standard glass-foil design.

The Business Case: A Domestic Production Opportunity in Moldova

Establishing a local facility to produce these specialized modules offers a distinct competitive advantage over importing generic panels, creating a solution tailored to the specific needs of Moldova’s economy.

Addressing Moldova’s Core Challenges

A domestic APV module factory directly addresses national-level issues:

- Energy Security: Local manufacturing reduces dependence on international supply chains for critical energy infrastructure and helps build a resilient, decentralized power grid.

- Agricultural Modernization: It provides Moldovan farmers with a cutting-edge tool to combat climate change, improve water efficiency, and stabilize their incomes.

- Economic Development: Such a venture creates skilled manufacturing jobs, fosters technical expertise within the country, and positions Moldova as a regional innovator.

The Market Advantage of Local Manufacturing

From a business perspective, local production also offers clear advantages:

- Product Customization: A domestic factory can work directly with agronomists and large agricultural enterprises to design modules optimized for Moldova’s primary crops.

- Logistical Efficiency: Manufacturing in-country eliminates the high costs and risks associated with shipping large, fragile glass modules across continents.

- Supply Chain Control: A local producer can offer shorter lead times and more reliable availability compared to relying on international suppliers.