The most sophisticated solar module production machine is of little use if it cannot reach its destination. For entrepreneurs establishing factories in coastal nations, the journey from the manufacturer’s port to the local industrial park is a relatively standard logistical exercise.

For those in landlocked countries, however, the final leg of this journey becomes a complex challenge that can define a project’s success or failure. The last few hundred kilometers overland can often prove more demanding than the thousands of nautical miles across the ocean.

This article explores the unique logistical hurdles of transporting heavy, sensitive production machinery to a landlocked country, using a project in Nepal as a practical example. It offers a framework for understanding the process, anticipating challenges, and implementing strategies for a successful delivery.

The Unique Challenge: Navigating Transit Corridors

A landlocked nation, by definition, lacks direct access to the sea. This geographic reality makes it entirely dependent on its neighbors for international trade. All seaborne cargo, including heavy factory equipment, must arrive at a port in a neighboring country and then be transported overland through a ‘transit corridor.’

For Nepal, this corridor primarily runs through India. Heavy machinery destined for a Nepalese factory typically arrives at an Indian port, most commonly Kolkata or Haldia. From there, it begins a challenging overland journey to a border crossing like Birgunj before continuing to its final destination within Nepal. This dependency introduces several layers of complexity not faced by projects in coastal regions:

-

Infrastructure Reliance: The entire operation depends on the quality and capacity of a foreign country’s roads, bridges, and railways.

-

Cross-Border Bureaucracy: The shipment must clear customs not once, but twice—first for transit through the neighboring country and again upon import into the destination country.

-

Coordination Complexity: Multiple logistics providers, regulatory bodies, and languages are often involved, increasing the potential for miscommunication and delays.

Mapping the Journey: From Seaport to Factory Floor

The physical movement of the machinery is a multi-stage process, and each step presents distinct challenges that require meticulous planning.

The Maritime Leg and Port of Entry

The journey begins with standard sea freight to a designated port of entry. For Nepal, this is usually Kolkata in India. Here, meticulous documentation is paramount. Any discrepancies in the Bill of Lading, Commercial Invoice, or Letter of Credit can lead to significant delays and storage (demurrage) fees at the port before the overland journey can even commence.

Navigating the Overland Transit Corridor

Once cleared for transit, the machinery is loaded onto specialized heavy-haulage trucks. This is often the most perilous part of the journey. The route from Kolkata to the Nepalese border traverses varied and unpredictable terrain.

Planners must account for narrow mountain passes, bridges with limited weight capacities, and poor road surfaces that can jostle sensitive equipment. Seasonal factors like the monsoon season (typically June to September) can cause landslides and road closures, halting transport for days or even weeks. This phase requires a transport provider with deep local knowledge to navigate the physical landscape safely.

The Critical Border Crossing

The border crossing, such as the one at Birgunj, is a significant potential bottleneck. Here, the cargo undergoes another round of rigorous customs inspections and documentation checks. Bureaucratic delays are common, and even minor errors in paperwork can hold up the entire shipment. Effective coordination and experienced customs agents are essential to ensure a smooth transition from the Indian transit corridor into Nepal.

Key Considerations for a Successful Operation

Successfully navigating these challenges requires more than just hiring a shipping company. It demands an integrated strategy that addresses financial, logistical, and risk-management factors.

Financial Planning: The Hidden Costs of Transit

The cost of logistics for a landlocked project can be substantially higher than for one in a coastal nation. Based on industry data, entrepreneurs should budget for transport costs 20–30% greater. Key cost factors to anticipate include:

-

Port Handling and Transit Fees: Charges for unloading at the foreign port and for using the transit corridor.

-

Customs Duties and Bonds: Duties are paid in the destination country, but a transit bond may be required in the transit country.

-

Specialized Inland Transport: The cost of heavy-haulage trucks and experienced crews is significant.

-

Comprehensive Insurance: Coverage must account for risks on the open sea, at the port, and across rough overland terrain.

-

Contingency for Delays: A budget for potential demurrage and other delay-related fees is a prudent measure.

Selecting the Right Logistics Partner

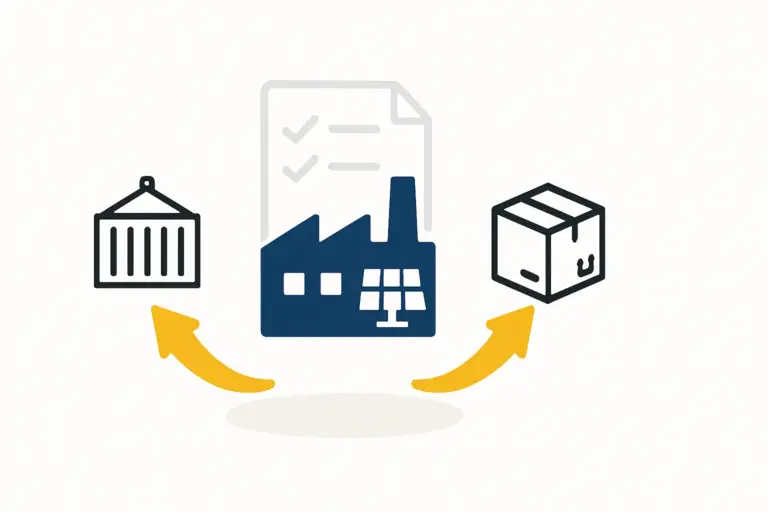

A common mistake is to fragment the logistical responsibility, with one company handling sea freight and another managing inland transport. This approach often leads to accountability issues when delays or damage occur.

Experience from J.v.G. turnkey projects shows that the most effective approach is to engage a single, qualified logistics partner responsible for the entire door-to-door process. This partner acts as the central point of coordination, managing everything from the initial sea freight to customs clearance and final inland delivery. This end-to-end model simplifies communication and ensures a single point of accountability—a critical advantage when navigating the complexities of a transit corridor. This holistic approach is a core component of a well-executed solar factory turnkey solution.

Proactive Risk Management and Timeline Buffering

A realistic project timeline must account for the high probability of delays. Planners should build a substantial buffer—several weeks, or even a month—into the schedule for the transport phase, especially if it coincides with periods of adverse weather like the monsoon season. This foresight prevents logistical hold-ups from derailing the entire project timeline, including machine installation and commissioning. This initial logistical planning is a crucial early step when considering how to start a solar factory.

Frequently Asked Questions (FAQ)

What is a transit corridor?

A transit corridor is a specific route through one country designated for the passage of goods to a neighboring, landlocked country. It involves agreements between the nations regarding customs, transport, and infrastructure use.

Why is documentation so critical for cross-border transport?

Every item must be perfectly documented on manifests, commercial invoices, and customs declarations. A single error can lead authorities in either the transit or destination country to halt the shipment, triggering inspections, fines, and costly delays.

How does the monsoon season impact project timelines?

The monsoon season brings heavy rains that can cause landslides, wash out roads, and make bridges impassable, particularly in mountainous regions like Nepal. This can halt transport for an unpredictable period, making it a major risk factor to include in any project schedule.

What kind of solar production machinery requires this special handling?

Key pieces of equipment, such as automated stringers, large-format laminators, and cell testers, are not only heavy but also contain sensitive electronic and mechanical components. They must be protected from excessive vibration and shock during transport over rough terrain to ensure they function correctly upon installation. The logistics must be integrated into the overall factory layout planning to ensure machines arrive in the correct sequence for installation.

Beyond Logistics: Integrating Transport into Project Planning

Transporting machinery to a landlocked nation is not a standalone task but an integral part of the overall project strategy. It demands meticulous advance planning, a realistic budget that accounts for higher costs, and the selection of an experienced logistics partner capable of managing the entire complex journey.

By understanding these challenges and preparing for them proactively, entrepreneurs can ensure that their state-of-the-art equipment arrives safely and on schedule, laying a solid foundation for a successful solar module manufacturing operation, no matter how remote the location.