Imagine the irony: a state-of-the-art solar module factory, built to advance energy independence, is forced to halt production by a local power outage. Sensitive machinery cools, in-process materials are ruined, and an entire day’s output is lost.

For entrepreneurs planning to enter the solar manufacturing sector in a market like Papua New Guinea, this scenario is not a distant possibility. It’s a critical business risk demanding a strategic solution from day one.

A high-technology manufacturing facility can only succeed with a constant, stable, and high-quality supply of electricity. In regions where public grid infrastructure is unpredictable, planning for power resilience is as fundamental as selecting the right production equipment. We’ll explore the specific electrical infrastructure challenges in Papua New Guinea and outline the business case for integrating on-site power generation and storage to safeguard a factory’s operations and profitability.

The State of Papua New Guinea’s Electrical Grid

Mitigating operational risks begins with understanding the local energy landscape. Papua New Guinea’s electricity sector is managed by the state-owned utility, PNG Power Ltd. (PPL). While efforts are underway to expand access, the national grid serves only about 13% of the population and presents several key challenges for industrial users.

Rather than a single national network, the grid is fragmented into three primary, unconnected systems: the Port Moresby grid, the Ramu grid, and the Gazelle Peninsula grid.

This fragmentation means that reliability in one region does not translate to another. The country’s power generation relies heavily on aging hydropower facilities and diesel generators. This combination, coupled with transmission challenges, results in frequent power interruptions (blackouts) and voltage fluctuations (brownouts). A 2014 World Bank survey identified the electricity supply as the single greatest constraint for businesses operating in PNG—a challenge that persists in key industrial areas today.

- Lae (Ramu Grid): As the nation’s industrial center, Lae is served by the Ramu grid, which is predominantly powered by hydropower. However, its reliability is often compromised by transmission line issues and seasonal variations in water levels, compelling most industrial operators to rely on extensive backup power systems.

- Port Moresby (POM Grid): The capital’s grid benefits from a more diverse mix of gas, hydro, and diesel generation. While generally considered more stable than the Ramu system, it is not immune to outages that can disrupt sensitive manufacturing operations.

Why Stable Power is Non-Negotiable for Solar Module Manufacturing

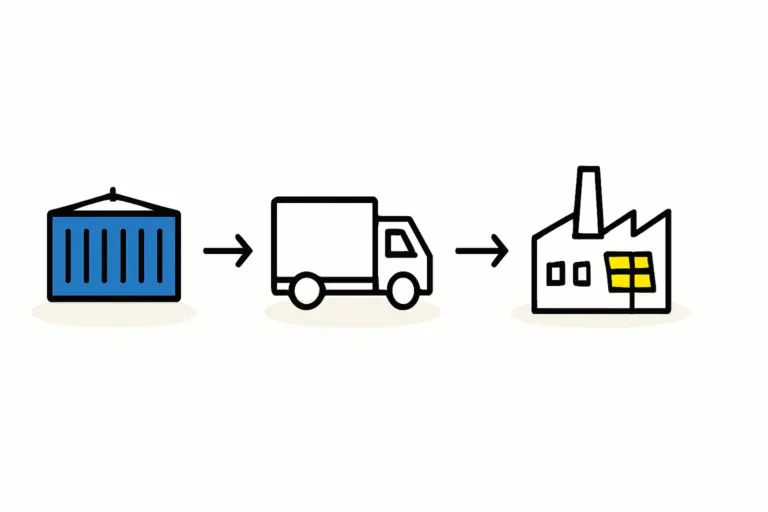

A solar module factory is not like a typical warehouse or assembly plant. The solar module manufacturing process involves several stages using machinery that is highly sensitive to power quality. A typical 50 MW production line requires a continuous supply of 250–400 kW. Any deviation can have immediate and costly consequences.

The equipment most vulnerable to power disruptions includes:

- Stringers: These automated machines solder solar cells together with extreme precision. A sudden power loss can cause misalignments, damage cells, and require a time-consuming recalibration process.

- Laminators: This is arguably the most critical stage. Modules are heated under a vacuum to over 140°C for a precise duration to cure the encapsulant material. An interruption during this thermal process can render an entire batch—often containing dozens of modules—unusable.

The financial impact of a single outage extends beyond lost production time. An outage leads to direct material waste, as partially processed cells, glass, and encapsulants must be discarded. This is not a minor inconvenience; it is a significant blow to the factory’s bottom line.

Analyzing Power Solutions for Industrial Operations in PNG

Given the grid’s limitations, a prospective factory owner must evaluate alternative power strategies. Relying solely on the grid is not a viable business model for high-tech manufacturing in this environment.

The Common Fallback: Diesel Generators

For decades, the standard response to unreliable power has been on-site diesel generators. While they provide a necessary backup, they come with significant drawbacks, including high and volatile fuel costs, demanding maintenance schedules, noise, and environmental emissions. Over the long term, the operational expenditure (OPEX) of a diesel-centric strategy can severely erode profitability.

The Resilient Solution: On-Site Solar PV and Battery Storage (BESS)

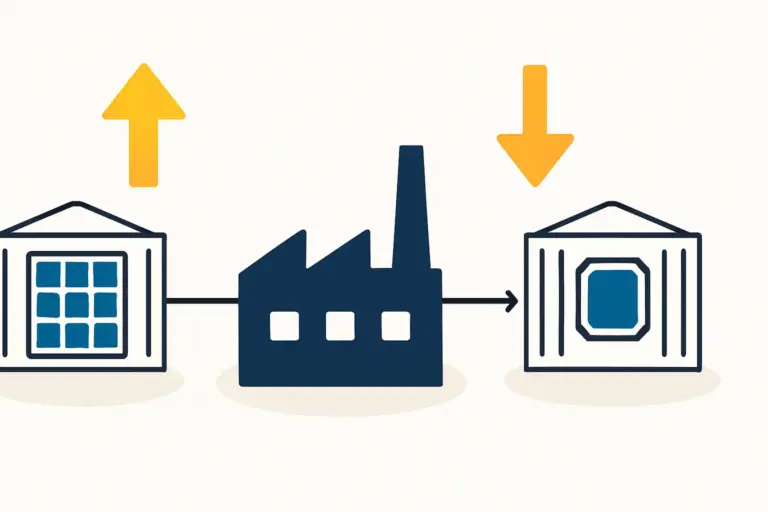

A more modern and economically sound approach is a hybrid power system integrating on-site solar generation with a Battery Energy Storage System (BESS). This solution is designed to deliver seamless, high-quality power, regardless of the grid’s status.

A typical configuration includes:

- Grid Connection: Used as a backup or for non-critical loads.

- Solar PV Array: Generates clean electricity during the day, directly powering the factory and charging the batteries.

- Battery Energy Storage System (BESS): Stores excess solar energy and provides instantaneous, uninterrupted power to critical machinery during grid outages or at night.

- Backup Generator: Can be included for an additional layer of redundancy for prolonged grid failures.

This integrated system transforms the factory from a passive consumer into a resilient, self-sufficient operation. Beyond ensuring continuity, it carries a powerful branding message: a solar module factory powered by its own solar technology.

The Business Case: Comparing Costs and Returns

While a hybrid power system requires a higher initial investment than a simple diesel generator setup, the long-term financial case is compelling. This is driven primarily by a drastic reduction in operational expenditure. By prioritizing self-generated solar power, the factory minimizes its reliance on expensive grid electricity and diesel fuel.

Experience from J.v.G. turnkey projects in emerging markets shows that factories that integrate on-site renewable power solutions from the outset achieve higher production uptime, greater cost predictability, and a faster path to profitability. This investment should not be viewed as an add-on, but as a core component of a modern turnkey solar factory designed for resilience and long-term success.

Frequently Asked Questions (FAQ)

How much power does a small-scale solar factory need?

A typical semi-automated solar module production line with an annual capacity of 20–50 MW will have a peak power demand of approximately 250–400 kilowatts (kW). This power must be stable and continuous for critical equipment.

Can a factory run entirely on solar and batteries?

Technically, yes. However, for 24/7 operation and 100% redundancy, the most practical and cost-effective solution is often a hybrid system. This setup uses solar and batteries as the primary source, with the grid or a small backup generator available for extended periods of bad weather or maintenance.

What is the biggest risk of unstable power to the machinery?

For the laminator, the primary risk is ruining the entire batch of modules if the thermal cycle is interrupted. For electronically controlled equipment like stringers and testers, sudden voltage spikes or drops can damage sensitive control boards, leading to costly repairs and extended downtime.

Does this issue apply only to PNG?

No. The challenge of grid instability is a critical consideration for industrial projects in many developing and emerging markets across Africa, Southeast Asia, and Latin America. The strategic principles of designing a resilient, on-site power system are universally applicable where grid reliability is a concern.

For any entrepreneur planning to establish a solar module factory in Papua New Guinea, the power infrastructure cannot be an afterthought. The inherent unpredictability of the local grid makes an on-site hybrid power system a fundamental requirement for operational continuity and financial viability. By engineering a solution that leverages solar and battery storage, a factory can de-risk its operations, control energy costs, and build a truly resilient business poised for success.