Imagine your shipment of high-value solar manufacturing equipment has safely arrived at the port. That container holds the key to launching your new enterprise.

But in a market as unique as Papua New Guinea, this arrival isn’t the end of the logistical journey—it’s merely the beginning. The path from the port to your factory, and later the distribution of finished solar modules, presents a unique set of challenges that demand a well-considered strategy.

For entrepreneurs and investors looking to establish a solar production facility in PNG, understanding the local supply chain is as critical as mastering the technology itself. This is not a market where standard global logistics models can be applied without significant adaptation.

From port infrastructure to the final mile of delivery, every step requires foresight, planning, and local expertise. This article outlines the primary logistical considerations for establishing and operating a solar module factory in Papua New Guinea and provides a framework for navigating this complex terrain.

The First Hurdle: Port Selection and Inbound Logistics

The entry point for all imported goods, including sensitive solar manufacturing equipment and raw materials, is through one of PNG’s major ports. Choosing the right one is the first strategic decision an operator must make.

Key Port Considerations

Papua New Guinea has two primary international ports:

-

Port of Lae: As the country’s largest and busiest port, Lae serves as the main gateway to the Highlands region and is often the default choice for industrial cargo. Its connection to the Highlands Highway makes it a strategic hub for inland distribution.

-

Port Moresby: Located in the nation’s capital, this port primarily serves the southern region. While it has modern facilities, its geographical isolation from the economic centers of the Highlands can make it less practical for factories located further inland.

However, selecting a port is not just about location. Operators must contend with several realities:

-

Infrastructure Limitations: Both ports have draft limitations that may restrict the size of vessels that can dock, influencing shipping routes and lead times.

-

Congestion and Efficiency: Port congestion is a common issue that can cause delays in unloading cargo. The availability and condition of handling equipment, like cranes and forklifts, can also impact turnaround times.

-

Customs and Bureaucracy: Navigating customs in PNG can be a complex and time-consuming process. Incomplete or incorrect paperwork can result in significant delays and extra costs. Experience shows that partnering with a skilled local customs broker isn’t just advisable—it’s essential for a smooth process.

The Inland Challenge: Transporting Materials and Modules

Once cleared from the port, the next phase of the logistical puzzle begins: inland transportation. For much of the country, this journey relies almost exclusively on the Highlands Highway, a route that is both an economic lifeline and a significant operational risk.

The Realities of the Highlands Highway

The highway connects the port of Lae to the populous Highlands region. However, its condition presents constant challenges:

-

Poor Road Conditions: Large sections of the highway are unpaved, poorly maintained, and susceptible to damage from heavy rains. This not only slows transit times but also increases the risk of damage to sensitive cargo, such as solar glass or precision machinery.

-

Security Risks: The route is known for security concerns, including landslides (both natural and man-made) and the risk of interception by local gangs, known as ‘raskols.’ Secure transport arrangements, often involving convoys or local security escorts, are a necessary operational expense.

-

High Costs: Due to the difficult terrain, security requirements, and wear and tear on vehicles, the cost of road freight in PNG is significantly higher than in more developed markets. These costs must be factored into the business model for both inbound raw materials and outbound finished products.

Alternative transport methods like rail are non-existent, and air freight is prohibitively expensive for the bulk materials needed in solar manufacturing. Mastering road logistics is therefore essential for a successful operation.

Securing Your Assets: Warehousing and Storage Strategy

A reliable supply chain requires more than efficient transport; it also demands secure, appropriate storage for both raw materials and finished modules. In PNG, finding suitable warehousing presents another significant challenge.

Climate and Infrastructure Considerations

Modern, climate-controlled warehousing facilities are limited and often concentrated near the main ports. This presents two problems:

-

Protecting Raw Materials: Many of the raw materials for solar panels, particularly polymers like Ethylene Vinyl Acetate (EVA), are highly sensitive to humidity and temperature fluctuations. Improper storage can compromise material quality, leading to production defects and reduced module lifespan. The tropical climate of PNG makes climate control an absolute necessity.

-

Strategic Inventory Management: Given the potential for transport delays, holding a buffer stock of critical materials is a prudent strategy. A factory must have adequate, secure on-site or near-site storage. The design of a turnkey solar module factory should include a detailed plan for warehousing that accounts for these local conditions.

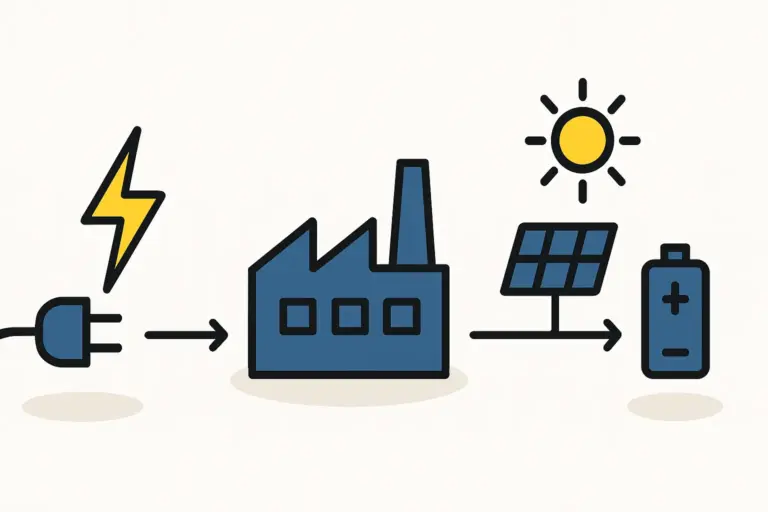

Broader Operational Realities

Beyond the primary logistics chain of transport and storage, other infrastructural factors influence day-to-day operations. The unreliable national power grid, for instance, requires investment in backup power generators.

This creates a secondary logistical requirement: a consistent and secure supply of fuel, which must also be transported and stored safely.

Engaging with local communities along transport routes is another key part of a successful strategy. Building positive relationships can help mitigate security risks and facilitate smoother passage, transforming a potential liability into a collaborative partnership.

Frequently Asked Questions (FAQ)

What are the main logistical bottlenecks for a solar factory in PNG?

The primary bottlenecks are port congestion and customs clearance for inbound goods, followed by the slow and hazardous conditions of the Highlands Highway for inland transport.

How important is a local logistics partner?

A reliable local partner with deep knowledge of customs procedures, transport routes, and security protocols is critical. Their expertise can save a project significant time and money by anticipating and solving problems a foreign operator might not foresee.

Can standard global supply chain models be applied in PNG?

No. Standard ‘just-in-time’ delivery models are generally unworkable due to the unpredictability of transport. A successful model in PNG must incorporate larger inventory buffers, longer lead times, and robust contingency plans.

What is a common hidden cost in PNG logistics?

Security is a major operational cost that is often underestimated during initial planning. This includes not only direct security escorts for valuable shipments but also the cost of losses or delays due to security incidents. Another common hidden cost is demurrage charges at the port due to customs delays.

How does the climate impact material storage?

The high humidity and heat in PNG can quickly degrade sensitive materials like EVA and backsheets if not stored in a climate-controlled environment. This can lead to delamination and other quality issues in the finished solar modules. Proper warehousing is not a luxury but a core requirement for product quality.

Planning for Success

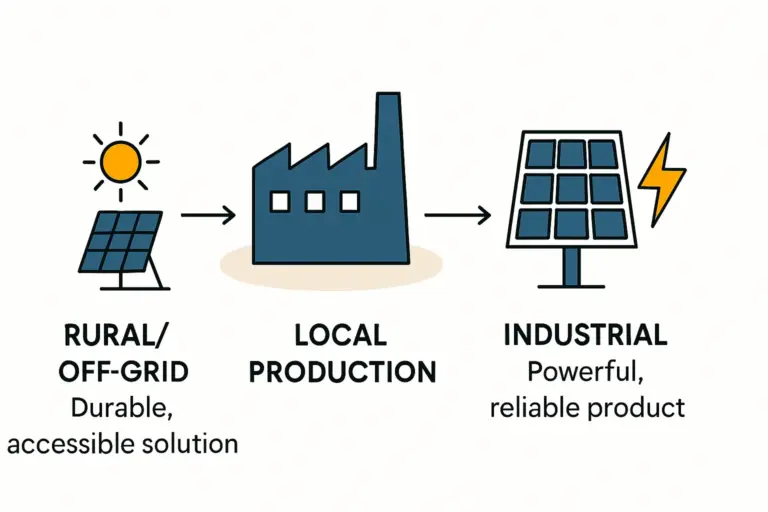

Entering the solar manufacturing sector in Papua New Guinea offers immense opportunity, but it requires a business plan grounded in local realities. The logistical challenges—from port to factory to final customer—are substantial but not insurmountable.

Success depends on meticulous planning, a conservative approach to timelines and budgets, and strong local partnerships. By acknowledging and strategically addressing these supply chain complexities from the outset, investors can build a resilient, profitable solar manufacturing operation capable of thriving in this unique and promising market.