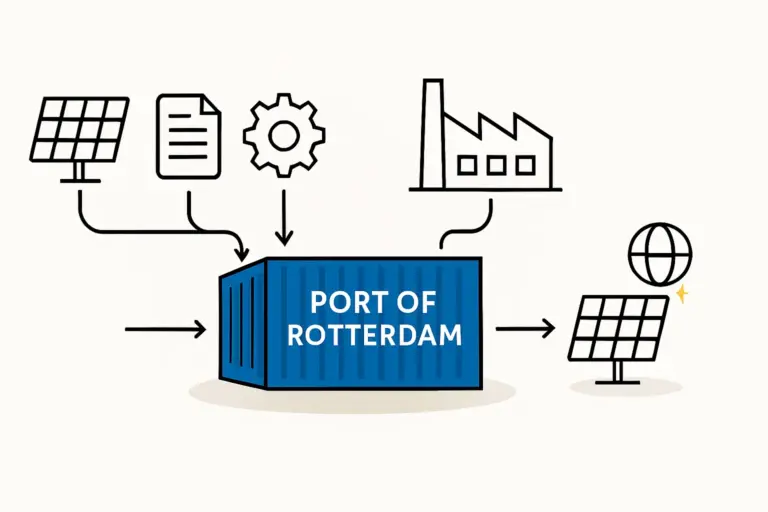

An investor planning to establish a new solar module factory often prioritizes proximity to a major seaport. As Europe’s largest, the Port of Rotterdam naturally draws significant attention. Yet focusing solely on port access overlooks a nuanced set of strategic factors that determine a project’s long-term profitability and operational efficiency.

The optimal location is rarely the most obvious one; it’s the site that best balances logistics, labor, and the local business ecosystem.

The Netherlands makes a compelling case for investment in advanced manufacturing, thanks to its world-class infrastructure and pro-business environment. Yet the country is not a monolith. The choice between a high-tech hub like North Brabant, a logistics gateway like Limburg, or a spacious, modern region like Flevoland carries significant implications for everything from supply chain management to workforce recruitment.

This guide offers a comparative analysis of these three key provinces to help entrepreneurs evaluate which region best aligns with their specific manufacturing strategy.

Foundational Criteria for Site Selection in the Netherlands

A comprehensive site selection process balances three core pillars. Although these criteria are universal, applying them within the Dutch context reveals distinct regional advantages.

-

Logistics and Infrastructure: Beyond port access, this pillar includes motorway connectivity, rail freight capacity, inland water transport, and proximity to key European markets. The efficient distribution of finished modules is just as critical as the import of raw materials.

-

Labor and Technical Expertise: The availability of skilled engineers, technicians, and production line operators is fundamental. Proximity to technical universities, vocational training centers, and established industrial clusters can significantly reduce recruitment challenges.

-

Business Environment and Costs: This pillar covers the availability and cost of suitable industrial land, local tax incentives, the presence of a supportive supply chain, and the proactiveness of regional development agencies.

Province Analysis 1: North Brabant – The High-Tech Manufacturing Hub

Overview and Strategic Location

Situated in the south of the Netherlands, North Brabant is widely recognized as the country’s high-tech manufacturing heartland. It offers excellent connectivity to the ports of Rotterdam and Antwerp (Belgium) and shares a border with Germany’s industrial core, making it a premier choice for businesses reliant on advanced technology and sophisticated supply chains.

Logistics and Infrastructure

A dense network of major motorways, including the A16, A2, and A58, crisscrosses the province, ensuring rapid transit to major European destinations. North Brabant’s true advantage, however, lies in its high-tech ecosystem centered around the Brainport Eindhoven region. This area is a global hub for technology and design, offering unparalleled access to innovation and automation partners. In addition, inland container terminals like the one in Tilburg provide efficient, non-road alternatives for freight movement to and from the main seaports.

Labor and Technical Expertise

North Brabant is home to the Eindhoven University of Technology and numerous applied science universities, producing a steady stream of highly qualified engineering talent. The workforce is skilled in mechatronics, process management, and precision manufacturing—disciplines directly relevant to operating modern, automated solar production facilities. Thoughtful planning for skilled labor is a crucial component of any factory setup, and North Brabant offers a deep talent pool to draw from.

Business Environment and Costs

The concentration of high-tech industries means land and labor costs can be higher here than in other provinces. However, this premium is often offset by superior access to a world-class supply chain for robotics, machine parts, and specialized electronics—an advantage that can reduce lead times and foster collaborative innovation.

Province Analysis 2: Limburg – The Gateway to Mainland Europe

Overview and Strategic Location

Located in the southeasternmost part of the country, Limburg is uniquely positioned as a crossroads bordering both Germany and Belgium. This geography makes it a natural logistics hub for distribution into the European mainland, particularly the densely populated German Ruhr area.

Logistics and Infrastructure

Limburg’s primary strength is its trimodal infrastructure, which seamlessly integrates road, rail, and water transport. The province is bisected by the Meuse river, enabling cost-effective barge transport. The logistics hotspot of Venlo exemplifies this efficiency; according to the Invest in Holland Agency, over 170 million consumers are reachable within a 500-kilometer radius. All this makes Limburg an exceptional choice for manufacturers prioritizing low-cost, high-volume distribution of finished modules.

Labor and Cross-Border Workforce

The province benefits from a cross-border labor market, allowing employers to recruit from adjacent regions in Germany and Belgium. This considerably expands the available talent pool, particularly for skilled technicians and logistics professionals. The local workforce also has a strong tradition in manufacturing and logistics, ensuring a practical, hands-on skill set. Evaluating these human resource factors is a key part of understanding investment requirements for a solar factory.

Business Environment and Incentives

Industrial land prices in Limburg are generally more competitive than in North Brabant or the western Randstad region. Regional development agencies, such as the Limburg Development and Investment Company (LIOF), are known for providing robust support and financial incentives to new businesses establishing a presence in the area.

Province Analysis 3: Flevoland – The Modern, Spatially-Aware Choice

Overview and Strategic Location

As the Netherlands’ newest province, Flevoland was engineered from the ground up on reclaimed land. This unique history means the province was designed from the start with modern logistics and business needs in mind. It offers something increasingly rare in the Netherlands: space. Its central location also provides excellent access to Amsterdam, Schiphol Airport, and the rest of the country.

Logistics and Infrastructure

Flevoland boasts modern, uncongested motorways (A6, A27) and is developing its inland port capabilities. Its primary logistical advantage is the absence of legacy constraints found in older industrial areas, which translates into smoother traffic flow and more predictable transit times—a significant operational benefit.

Labor and Growth Potential

While the local labor pool is smaller than in the more established provinces, Flevoland’s growing residential areas and excellent connectivity attract a significant commuting workforce from the greater Amsterdam and Utrecht regions. The province has a forward-looking mindset and is actively working to attract skilled labor to support its expanding industrial base.

Business Environment and Land Availability

Flevoland’s most compelling feature for a manufacturer is the availability of large, relatively affordable plots of industrial land. This is critical for designing a factory with an optimal layout and room for future expansion, as the solar factory building requirements often dictate a significant physical footprint. Flevoland is one of the few places in the country that can readily accommodate this need. Its municipal governments are also highly proactive, with streamlined processes for attracting new investment.

Comparative Summary and Decision Matrix

The ideal province depends entirely on an investor’s strategic priorities.

For High-Tech Integration and Automation: North Brabant is the clear leader, offering access to an unparalleled ecosystem of technology partners and skilled engineers.

For Pan-European Logistics and Distribution: Limburg excels with its trimodal transport options and strategic location at the heart of Europe’s consumer market.

For Space, Scalability, and Modern Infrastructure: Flevoland provides the land and modern planning necessary for large-scale operations designed for future growth.

Based on experience from J.v.G. turnkey projects, a data-driven evaluation matrix is often used to weigh these factors against a client’s specific business model before recommending a location for new turnkey solar manufacturing lines.

Frequently Asked Questions (FAQ)

Why is the Netherlands a good choice for solar manufacturing in Europe?

The Netherlands combines a strategic geographic location with political stability, a highly educated and multilingual workforce, and world-class logistics infrastructure. Together, these factors create a reliable and efficient environment for manufacturing operations serving the entire European continent.

Are there national incentives in addition to provincial support?

Yes, the Dutch government offers several national incentives. The WBSO (Research and Development Tax Credit), for instance, provides a tax advantage for companies engaging in R&D, which can apply to process innovation in solar module manufacturing.

How important is proximity to a major seaport like Rotterdam?

While proximity to a port is beneficial for importing raw materials like glass and aluminum frames, it is not the only factor. Excellent inland road, rail, and waterway connections mean that a factory located in Limburg or North Brabant can receive container freight just as efficiently. For distributing finished goods across Europe, an inland location can often be more advantageous.

What is a common mistake investors make when selecting a site?

A frequent oversight is to focus exclusively on the purchase price of the land, ignoring the potentially higher operational costs down the line from transportation bottlenecks, labor shortages, or a lack of local technical support. A holistic assessment that balances initial capital outlay with long-term operational efficiency is essential.

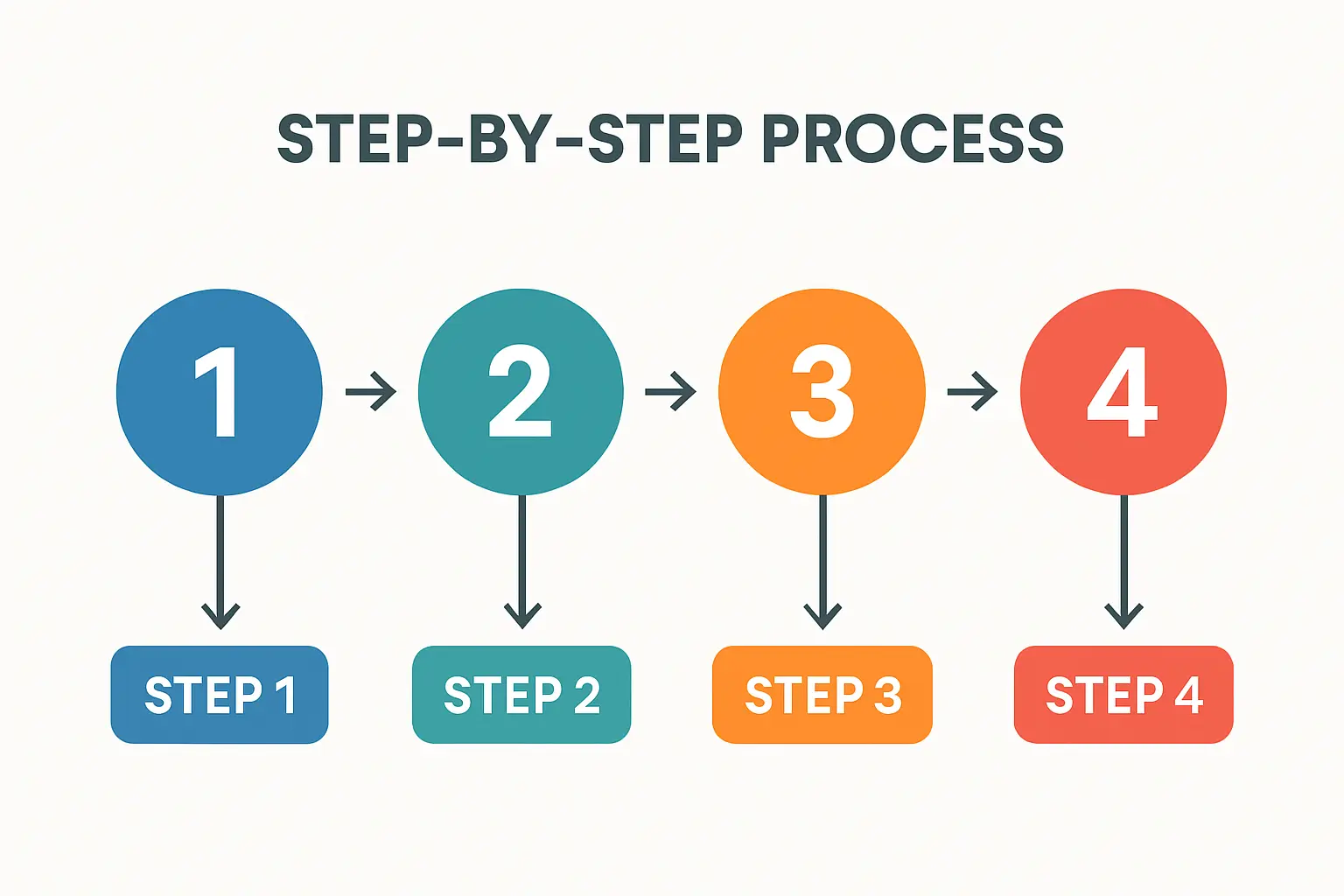

Next Steps in Your Planning Process

Site selection is a foundational decision that influences nearly every subsequent aspect of a manufacturing project. Once a primary region has been identified, the next logical step is a detailed feasibility study involving a granular analysis of specific industrial parks, local zoning laws, utility connections, and supply chain logistics.

This phase runs parallel to planning for other critical milestones, such as obtaining solar module certifications required for the target sales markets. A well-researched site selection process does more than just secure a location; it lays the groundwork for a resilient and profitable manufacturing operation for years to come.