As Qatar advances its National Vision 2030, diversifying the economy through industrialization and renewable energy has become a national priority. For entrepreneurs entering the solar manufacturing sector, establishing a production line is only one part of the equation.

An often-underestimated challenge lies in creating a resilient and cost-effective supply chain for essential raw materials. The success of a new solar module factory hinges on a strategic approach to sourcing its core components.

This guide lays out a framework for evaluating the two primary sourcing strategies for a solar manufacturer in Qatar: leveraging the growing industrial capacity of the GCC region versus using the global logistics network via Hamad Port. Understanding the trade-offs between these approaches is key to building a competitive and sustainable operation.

Understanding the Bill of Materials for Solar Module Production

Before analyzing sourcing strategies, it’s essential to understand the primary components of a photovoltaic module. While dozens of materials are involved, four categories represent the bulk of the cost and logistical considerations.

The Four Key Components

-

Solar Glass: This specially formulated, high-transparency, low-iron tempered glass protects the solar cells from the elements while maximizing light absorption. It is the heaviest component of a panel.

-

Encapsulant (EVA): Ethylene Vinyl Acetate (EVA) is a polymer resin film used to laminate the components, bonding the cells to the glass and backsheet while providing electrical insulation and moisture protection.

-

Backsheet: This is the rearmost layer of the module, typically made of a durable polymer composite. It acts as a moisture barrier and provides mechanical protection and electrical insulation.

-

Aluminum Frames: These extruded aluminum profiles provide structural rigidity to the finished module, protecting the edges of the glass laminate and simplifying mounting and installation.

Securing a reliable supply of these four materials is the cornerstone of an efficient manufacturing process.

Evaluating Sourcing Strategies: Regional GCC vs. International Imports

A new manufacturer in Qatar faces a critical choice: rely on established, high-volume international suppliers, primarily from Asia, or cultivate relationships with emerging regional suppliers within the Gulf Cooperation Council (GCC). This is not merely a logistical choice but a strategic one that impacts cost, risk, and long-term resilience.

Leveraging Qatar’s Industrial Strengths for Regional Sourcing

Qatar’s established industrial base, particularly in metals and petrochemicals, creates unique opportunities for sourcing key solar module materials locally or from neighboring countries. This approach offers significant advantages in logistics, lead times, and alignment with national industrial goals.

Aluminum Frames: The Local Advantage

Qatar is home to Qatar Aluminum (Qatalum), one of the world’s largest and most modern aluminum smelters, offering an immediate and powerful local sourcing advantage. By procuring frames from a domestic or regional extruder that uses Qatari aluminum, a manufacturer can:

-

Drastically reduce logistics costs: Eliminating international shipping for this bulky component yields substantial savings.

-

Shorten lead times: Delivery can be reduced from weeks or months to mere days, enabling more agile inventory management, provided the solar panel manufacturing process flow can accommodate just-in-time delivery.

-

Gain flexibility: Working with local suppliers allows for easier customization of frame profiles and a faster response to design changes.

Encapsulants (EVA) and Backsheets: Exploring GCC Potential

The foundation of EVA films and polymer backsheets is the petrochemical industry, another of Qatar’s core strengths. Major players like QatarEnergy and QAPCO, alongside regional giants like SABIC in Saudi Arabia, are world-class producers of the base polymers required.

While specialized, solar-grade film and sheet extrusion may still be an emerging capability in the region, the proximity of raw material production creates a strong business case for developing local manufacturing or strategic partnerships. Sourcing from a developing GCC supply chain can insulate a business from global price volatility and shipping disruptions.

Solar Glass: A Regional Consideration

Specialized solar glass production is concentrated in a few key markets globally. However, high-quality flat glass manufacturing exists within the GCC, notably in Saudi Arabia and the UAE. Procuring glass regionally can significantly de-risk the supply chain by reducing the transit distance for this heavy and fragile product, which lowers the chances of costly breakage and associated insurance premiums.

Hamad Port: Qatar’s Gateway to the Global Supply Chain

For components where regional suppliers may not yet be competitive in scale or technology—such as high-efficiency solar cells, specialized backsheets, or junction boxes—Qatar’s world-class logistics infrastructure offers a reliable alternative.

Hamad Port is one of the largest and most advanced deep-water ports in the Middle East, serving as a major transshipment hub with direct shipping lanes to key manufacturing centers in Asia and Europe.

Advantages of International Sourcing via Hamad Port:

-

Access to Scale and Cost Efficiency: Global suppliers, particularly in China, operate at an immense scale, often resulting in lower per-unit costs for materials.

-

Wide Range of Suppliers: Importing provides access to a vast marketplace of vendors, allowing manufacturers to select components based on the latest technology and performance specifications.

-

Established Processes: The global supply chain for solar components is mature, with established quality standards and logistics pathways.

Associated Risks of International Sourcing:

-

Longer Lead Times: Sea freight from Asia can take 6–8 weeks, requiring larger inventory holdings and more capital tied up in stock.

-

Geopolitical and Shipping Risks: Global events can disrupt shipping lanes, leading to unexpected delays and cost increases.

-

Currency Fluctuations: Transactions are typically conducted in foreign currencies (e.g., USD or RMB), exposing the business to exchange rate risk.

Effective management of these variables is crucial for controlling the overall investment required to start a solar panel factory.

Developing a Hybrid Sourcing Model for Maximum Resilience

For most new solar manufacturers in Qatar, the optimal approach is not an ‘either/or’ choice but a carefully constructed hybrid model. This strategy leverages the strengths of both regional and global supply chains to build a system that is cost-effective, agile, and resilient.

A practical hybrid model could look like this:

-

Regional Sourcing: Aluminum frames, and potentially glass, are sourced from suppliers within Qatar or the GCC to minimize logistics costs and lead times.

-

International Sourcing: High-tech, lower-volume components like solar cells, specialized EVA, and junction boxes are imported from leading global manufacturers to ensure access to the best available technology and price points.

This strategic flexibility is a hallmark of a well-designed solar panel manufacturing business plan. Based on experience from J.v.G. turnkey projects, a dual-sourcing strategy is often recommended for the most critical components. Maintaining both a regional and an international supplier is an effective way to mitigate single-point-of-failure risks.

Frequently Asked Questions on Solar Material Sourcing in Qatar

What is the most difficult material to source for a new factory in Qatar?

Typically, high-efficiency solar cells are the most challenging component. The production of solar cells is a highly technical and capital-intensive process concentrated in a few global hubs, primarily in East Asia, meaning they will almost certainly need to be imported.

Can I reduce costs by sourcing everything from China?

While the per-unit price of components from China may be lower due to economies of scale, the total landed cost can be significantly higher for certain items. Shipping heavy, bulky materials like glass and aluminum frames over long distances is expensive and carries a higher risk of damage. A blended approach that sources these heavy items regionally is often more cost-effective overall.

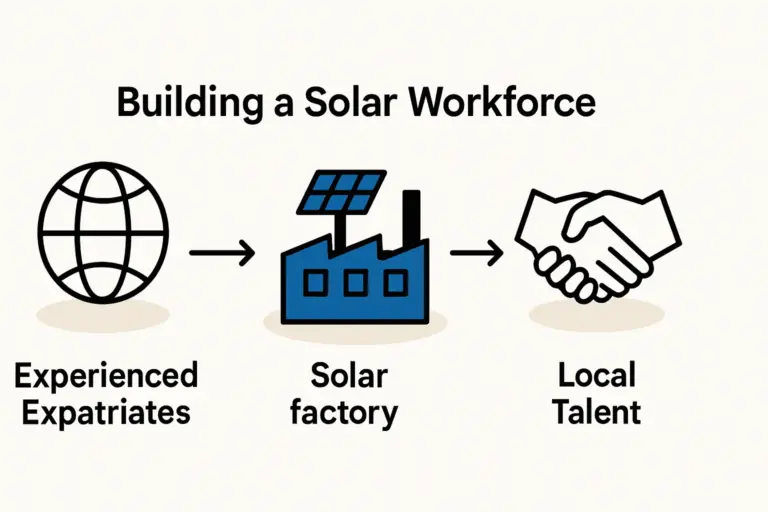

How does local sourcing support Qatar’s National Vision 2030?

Sourcing materials from within Qatar and the GCC directly supports the vision’s goals of economic diversification and industrial development. It helps build local manufacturing capabilities, reduces dependency on imports, creates skilled jobs, and contributes to the growth of a non-hydrocarbon-based economy.

What are the typical lead times for imported vs. regional materials?

As a general estimate, sea freight from major Asian ports to Hamad Port typically takes 6-8 weeks, plus time for customs clearance. In contrast, road freight from a supplier in a neighboring GCC country like Saudi Arabia or the UAE can often be completed in 1-2 weeks, offering a significantly faster turnaround.

Conclusion: Building a Future-Proof Supply Chain

The decision of how to source raw materials is as critical as the choice of production machinery. For an entrepreneur in Qatar, the landscape offers a unique combination of local industrial strength and world-class global connectivity. The most resilient and competitive solar manufacturing ventures will be those that strategically balance the cost benefits of global suppliers with the logistical security and speed of a regional supply network.

By carefully analyzing each component in the bill of materials and developing a flexible, hybrid sourcing strategy, a new solar enterprise can build a foundational advantage that will support its growth for years to come. For entrepreneurs navigating these initial planning stages, structured guidance is invaluable. The pvknowhow.com e-course offers a detailed framework for mastering supply chain logistics and other critical business setup requirements.