A state-of-the-art solar module production line is a significant investment. But even the most advanced machinery is ineffective if raw materials can’t arrive on time or finished products can’t reach their markets efficiently. For any new solar manufacturing enterprise, logistics isn’t a secondary concern—it’s a cornerstone of success. The choice of location, particularly its port infrastructure, can determine the profitability and scalability of the entire operation.

This article examines the strategic advantages of Panama’s port system as a model for optimizing a solar manufacturing supply chain, exploring the roles of its key ports, the customs environment, and the direct impact these have on importing essential materials and exporting finished solar modules.

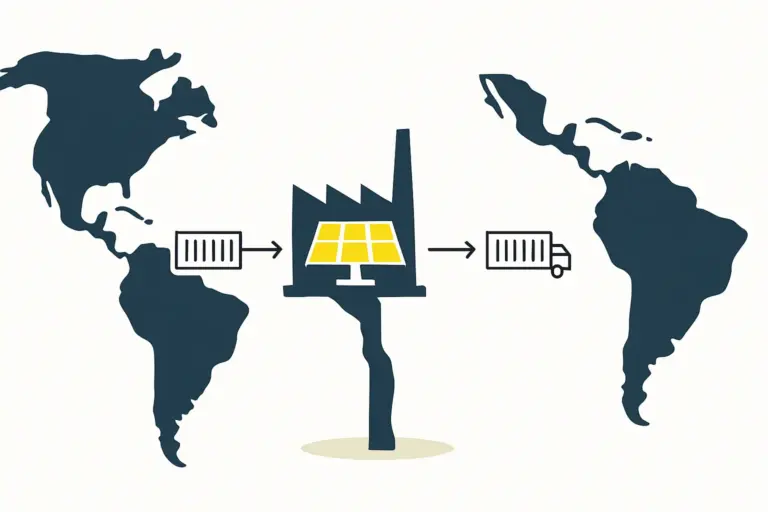

Why Panama’s Logistical Hub Matters for Solar Manufacturing

Panama’s geographical position is its most obvious asset. Situated at the crossroads of global trade, the country serves as a natural bridge between the Atlantic and Pacific oceans, connecting major markets in Asia, the Americas, and Europe. For a solar manufacturer, this translates into tangible benefits:

-

Access to Raw Material Suppliers: The majority of solar cells, specialized glass, and electronic components are sourced from Asia. Panama’s Pacific-facing ports offer direct and frequent shipping routes from these critical manufacturing hubs.

-

Proximity to Key Export Markets: The growing demand for solar energy in North, Central, and South America, as well as the Caribbean, puts a Panamanian factory in a prime distribution position.

-

Reduced Transit Times: The Panama Canal allows vessels to bypass the lengthy journey around South America, cutting weeks off shipping times and reducing inventory carrying costs. According to the Panama Canal Authority, the waterway serves over 144 maritime routes connecting 1,700 ports in 160 countries.

This strategic positioning creates an environment where a solar manufacturer can operate a lean, responsive supply chain that minimizes delays and maximizes market access.

The Twin Pillars of Panamanian Logistics: Balboa and Cristóbal

Panama’s logistical strength is anchored by two world-class container ports, one on each coast, working in tandem to facilitate global trade.

Port of Balboa: The Pacific Gateway

Located at the Pacific entrance to the Panama Canal, the Port of Balboa is one of Latin America’s busiest ports and the primary entry point for goods arriving from Asia. For a solar manufacturer, Balboa is the logistical gateway for critical raw materials.

Components such as solar cells, EVA films, backsheets, and aluminum frames—predominantly manufactured in countries like China, South Korea, and Vietnam—arrive through this port. Its deep-water access and advanced gantry crane systems allow it to handle the largest container ships, ensuring economies of scale for importers.

Port of Cristóbal: The Atlantic Connection

On the Atlantic side, near the city of Colón, lies the Port of Cristóbal. This port is the primary exit point for goods destined for the East Coast of the United States, Europe, and the Caribbean.

Once solar modules are manufactured, assembled, and packaged, they are transported to Cristóbal for export. Its direct routes to major consumer markets make it vital for reaching customers efficiently. The port’s integration with the Colón Free Zone further enhances its value for export-oriented businesses.

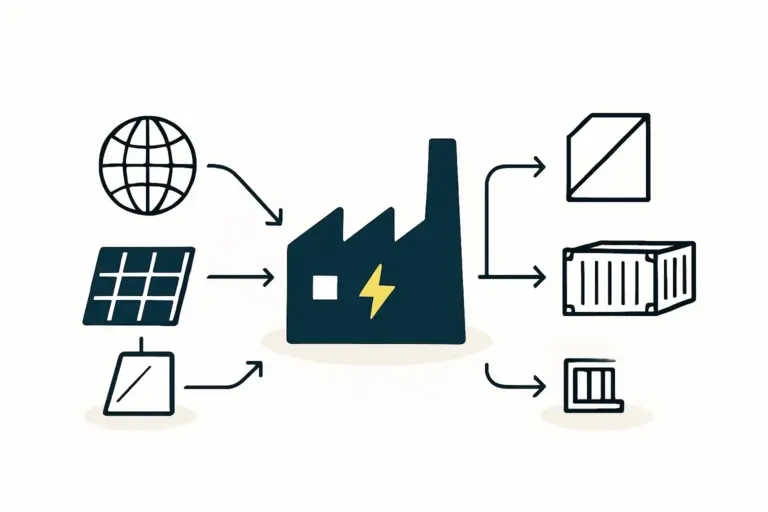

Navigating the Supply Chain: From Raw Materials to Finished Modules

Understanding the flow of goods is essential for planning a successful operation. The flow of goods through Panama’s logistical ecosystem can be understood in three key stages.

Importing Raw Materials

The supply chain begins with procuring the raw materials that solar panels are made of. A typical shipment for a 50 MW production facility might involve dozens of containers carrying everything from fragile solar cells to bulky rolls of glass. These goods are shipped from an Asian port, traverse the Pacific Ocean, and arrive at the Port of Balboa. From there, they are transported to the manufacturing facility, where the efficiency of port operations and inland transport directly impacts the production schedule.

The Role of Special Economic Zones (SEZs)

Panama is home to several Special Economic Zones, most notably the Colón Free Zone (CFZ) near the Port of Cristóbal. These zones offer significant advantages for manufacturing and trade. Businesses operating within an SEZ often benefit from:

-

Tax Incentives: Reduced or exempted taxes on imports, exports, and corporate income.

-

Streamlined Customs: Simplified and expedited customs clearance, reducing bureaucratic delays.

-

Integrated Logistics: Proximity to ports, airports, and major highways that creates a seamless logistics environment.

For a new solar manufacturer, establishing a facility within or near an SEZ can substantially lower operational costs and simplify the complexities of international trade.

Exporting Finished Solar Modules

After production, finished solar modules are carefully crated to prevent damage and transported to the Port of Cristóbal for export to markets in the Americas or Europe. The ability to quickly load and ship products is critical for meeting customer deadlines and managing cash flow. A well-organized logistics framework ensures that the investment for a solar panel manufacturing plant begins generating returns as quickly as possible.

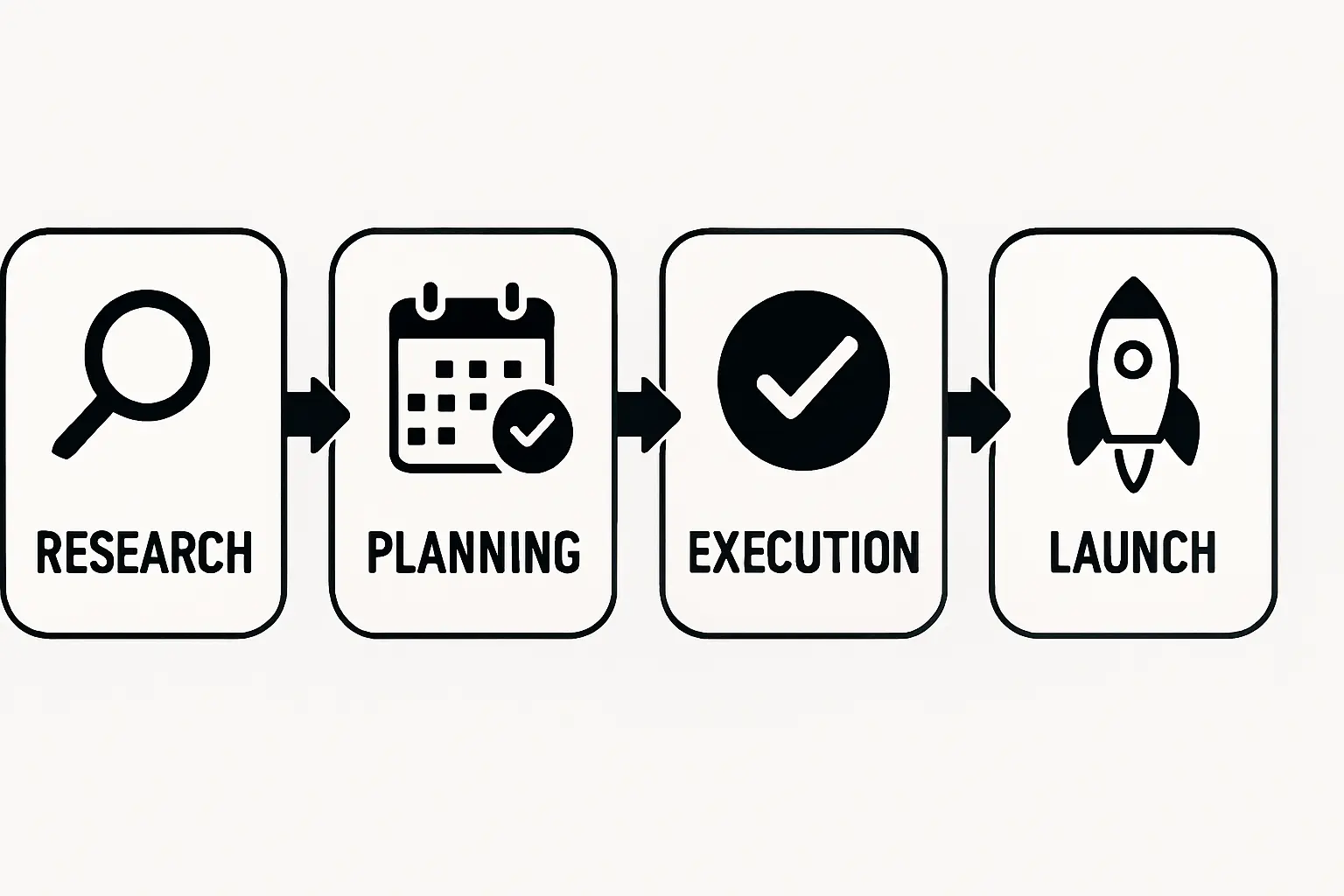

A Business-Level Perspective: What This Means for a New Solar Manufacturer

The technical details of port operations translate into clear business advantages. A robust logistical framework like Panama’s offers:

-

Predictable Timelines: Reliable shipping schedules and efficient customs allow for precise production planning.

-

Cost Control: High-volume shipping routes create competitive freight pricing, while SEZs reduce the tax burden.

-

Market Agility: The ability to source from Asia and sell to the Americas with minimal friction allows a business to adapt to changing market demands.

Experience from J.v.G. Technology’s turnkey projects shows that a thorough logistical analysis is fundamental to the planning phase. It often influences the final site selection, as proximity to efficient ports can be as crucial as access to a skilled workforce. This logistical efficiency is particularly valuable in regions that have high solar irradiation but historically complex import and export procedures.

Frequently Asked Questions (FAQ)

What is a Free Trade Zone or Special Economic Zone (SEZ)?

An SEZ is a designated geographical area within a country where business and trade laws differ from the rest of the country. These zones are created to attract foreign investment and boost trade, typically offering tax advantages and streamlined customs procedures.

How long does it typically take for goods to clear customs in Panama’s SEZs?

While times can vary, customs clearance within Panama’s SEZs is generally much faster than standard procedures. With proper documentation, goods can often be cleared within 24–48 hours, a significant advantage for maintaining a tight production schedule.

Are there specialized logistics providers for sensitive cargo like solar cells?

Yes, major logistics hubs like Panama have numerous freight forwarders and logistics companies specializing in fragile and high-value cargo. These providers offer services like climate-controlled warehousing and specialized handling to ensure materials like solar cells arrive without damage.

Does the choice of port affect the overall cost of a solar panel production line?

Indirectly, yes. While it doesn’t change the price of the machinery, an efficient port reduces shipping costs for both the initial equipment and ongoing raw materials. It also shortens the time-to-market, which means the cost of a solar panel production line can be recouped sooner. A location with poor logistics can lead to costly delays and higher operational expenses over the factory’s lifetime.

A successful solar manufacturing business is built on more than technical production capabilities; it requires a resilient, efficient, and cost-effective supply chain. A location like Panama, with its world-class ports and business-friendly economic zones, offers a powerful logistical model for building a globally competitive operation. Understanding these dynamics is a critical first step for any entrepreneur planning to enter this growing industry.