An entrepreneur can have a finalized business plan, robust financial models, and a clear market opportunity, yet the entire project can stall on a deceptively simple question: where, exactly, should the factory be built?

Choosing the right location for a solar module manufacturing plant is one of the most critical decisions in the venture. A poor choice can lead to unforeseen operational costs, logistical bottlenecks, and delays that erode profitability before the first module is even produced.

This is especially true in emerging markets like Nicaragua, where a promising landscape of opportunity comes with a unique set of infrastructural and regulatory considerations. This guide offers a framework for evaluating potential sites, focusing on the two foundational pillars of a successful location: reliable infrastructure and strategic zoning within Free Trade Zones (FTZs).

Why Infrastructure is the Foundation of Your Production Success

A plot of land is not just an empty space; it is a node in a complex network of utilities and logistics. For a sophisticated manufacturing operation like solar module production, the quality and reliability of this network are non-negotiable. Overlooking these factors in favor of cheaper land is a common but costly mistake.

Electricity Supply: The Lifeblood of Your Factory

Modern solar module manufacturing relies on sensitive, automated machinery that demands a constant, stable supply of electricity. Equipment like stringers, which precisely solder solar cells together, and laminators, which operate under specific heat and pressure profiles, are highly susceptible to power fluctuations.

While Nicaragua has made impressive strides, with nearly 80% of its electricity generated from renewable sources, grid stability can still be a concern in some areas. An unexpected power outage can halt production, ruin materials mid-process, and require a lengthy, expensive recalibration of machinery. A proper site evaluation must therefore go beyond simply confirming power availability.

Key considerations include:

- Grid Reliability: Investigate the historical performance of the local grid. How frequent are outages? Are there voltage fluctuations?

- Three-Phase Power: Confirm the availability of a high-capacity, three-phase electrical supply required for industrial machinery.

- Backup Solutions: It is wise to factor in the cost of backup power systems, such as diesel generators or battery storage, as an essential part of the initial investment. This ensures the solar panel manufacturing process remains uninterrupted.

Based on experience from J.v.G. turnkey projects, planning for power redundancy from day one is a critical step to mitigate risk in many regions.

Water Access: A Hidden but Essential Utility

While solar manufacturing is not as water-intensive as other industries, a consistent supply of clean water is still required for several key processes:

- Glass Washing: Ensuring solar glass is perfectly clean before lamination is crucial for module quality and longevity.

- Cooling Systems: Certain machinery may require water for cooling.

- Domestic Use: The facility will need water for its employees for sanitation and daily needs.

A potential site should have reliable access to a municipal water supply. If a municipal connection is unavailable, a thorough assessment of the feasibility and cost of drilling a well is necessary, including water quality testing.

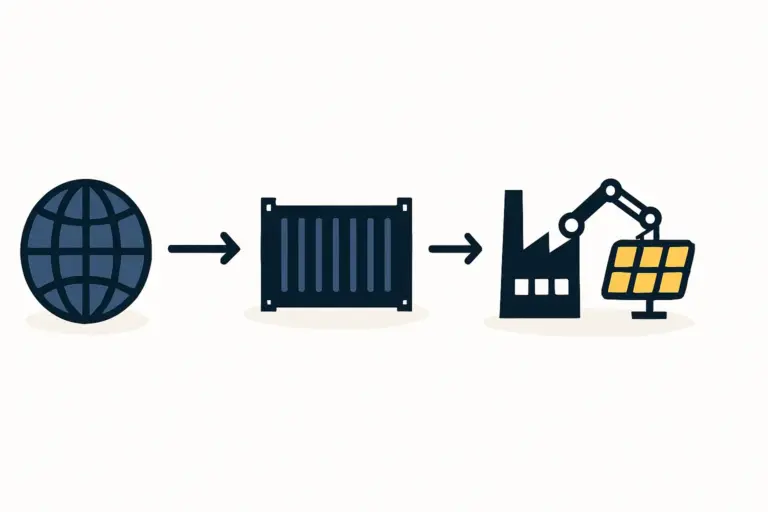

Transportation and Logistics: Connecting Your Factory to the World

Nicaragua’s strategic location, with access to both the Pacific and Atlantic oceans, is a significant advantage. However, this advantage can only be leveraged if the factory is well-connected to the country’s logistical backbone.

A factory requires a constant flow of inbound raw materials—like solar cells, glass, and aluminum frames—and outbound finished modules. Your site must have efficient access to:

- Major Ports: Proximity to key ports like Corinto on the Pacific coast is vital for importing materials and exporting to markets in the Americas and Asia.

- Major Highways: The site must be easily accessible for heavy trucks from main arterial roads like the Pan-American Highway. Poor road quality can lead to transport delays and damage sensitive materials.

Evaluating the ‘last mile’ of transit to and from the proposed site is just as important as the distance to the port.

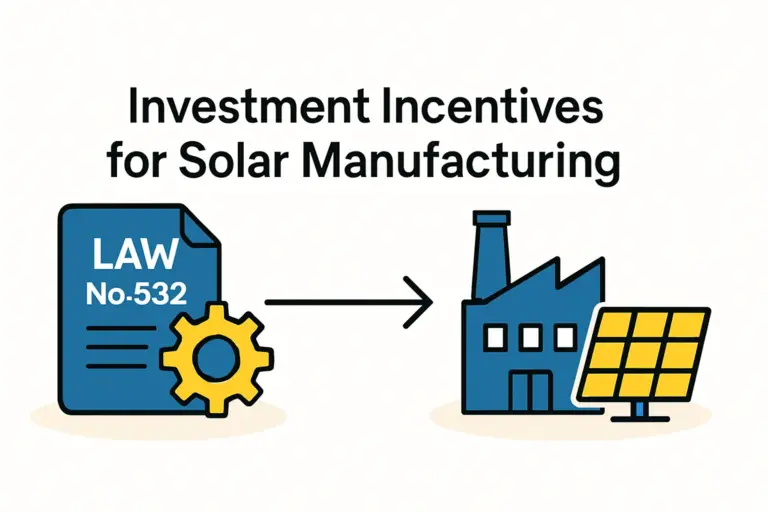

Strategic Positioning: Understanding Nicaragua’s Free Trade Zones

For foreign investors, one of Nicaragua’s most compelling incentives is its Free Trade Zone (FTZ) regime. Governed by the ‘Free Trade Zone Law’ (Decree No. 46-91), these designated areas offer significant financial and administrative benefits designed to attract manufacturing investment. Locating your plant within an approved FTZ is often the most logical business decision.

Key Advantages of Operating within an FTZ

The primary advantages include:

- Tax Exemptions: 100% exemption from corporate income tax for the first 10 years of operation.

- Duty-Free Imports: Complete exemption from customs duties and taxes on imported machinery, equipment, raw materials, and supplies needed for production.

- Exemption on Exports: No taxes on exported goods.

- VAT Exemption: 100% exemption from Value Added Tax (VAT).

These incentives dramatically lower both initial capital expenditure and ongoing operational costs, accelerating the path to profitability. A comprehensive understanding of these benefits is essential when evaluating the overall solar factory investment requirements.

Selecting the Right FTZ: Location Matters

While the legal benefits are standardized, not all FTZs offer the same practical advantages. Some are private industrial parks with modern, pre-built infrastructure, while others may be less developed.

When evaluating an FTZ, consider its proximity to Managua for administrative purposes, its connection to main transport arteries, and the availability of a skilled local workforce. Leading zones like Zona Franca Astro and Zona Franca Managua are popular due to their established infrastructure and strategic locations.

Building within an FTZ streamlines many bureaucratic hurdles, allowing an entrepreneur to focus on core business activities. A well-chosen site inside an FTZ creates the ideal foundation for a turnkey solar manufacturing line setup.

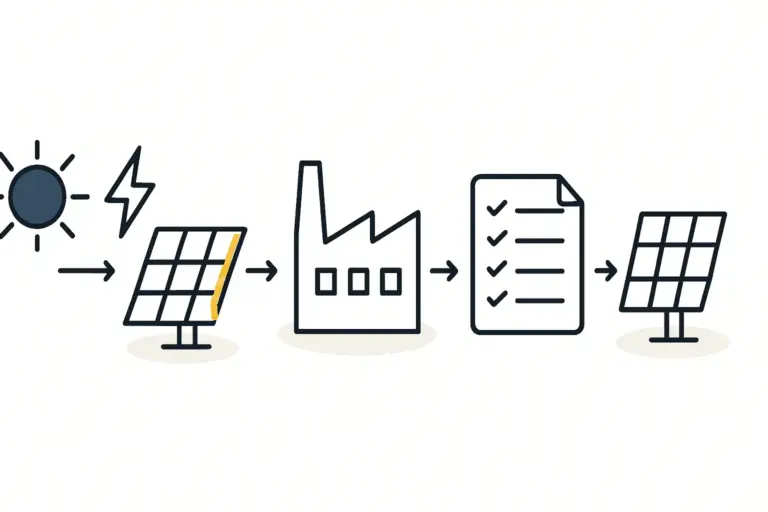

A Checklist for Your Site Assessment

To structure your evaluation, use the following checklist as a starting point for due diligence on any potential property:

-

Power Supply

Key Questions: Is a stable, three-phase power grid connection available? What is the cost of connection? What is the grid’s reliability record? -

Water Access

Key Questions: Is there a connection to the municipal water system? If not, what is the cost and legality of drilling a private well? -

Logistics

Key Questions: What is the distance and travel time to the nearest major port (e.g., Corinto)? Is the site easily accessible for large trucks? -

Zoning and Permits

Key Questions: Is the property located within a designated Free Trade Zone? What are the specific administrative requirements of that zone? -

Land and Title

Key Questions: Is the land title clear and free of disputes? What are the leasing or purchasing terms? -

Labor Pool

Key Questions: Is there a sufficient pool of trainable labor within a reasonable commuting distance? -

Geotechnical

Key Questions: Has a soil stability report been conducted to ensure the ground can support a heavy industrial building? -

Expansion

Key Questions: Does the site have sufficient space for future expansion of the production line or warehousing facilities?

Frequently Asked Questions About Site Selection in Nicaragua

How much land is required for a small-scale solar factory?

For a typical production line with a 20–50 MW annual capacity, a site of 5,000 to 10,000 square meters is usually sufficient. This accommodates the factory building, warehouse space for raw materials and finished goods, administrative offices, and room for logistics.

Can a foreign company own land in Nicaragua?

Yes, Nicaragua’s foreign investment laws grant foreign investors the same property rights as nationals. However, many companies in an FTZ choose to lease land or buildings within an established industrial park to simplify the process and gain access to pre-installed infrastructure.

What is the typical timeline for securing a site and starting construction?

The timeline can vary significantly. After identifying a suitable site, the due diligence process—including legal title checks, permitting, and finalizing lease or purchase agreements—can take three to six months. Engaging with experienced local legal and real estate advisors is highly recommended to navigate this phase efficiently.

Beyond infrastructure, what other site factors should be considered?

Important secondary factors include a geotechnical survey to assess soil stability for the factory foundation. You may also need an environmental impact assessment, depending on local regulations. Building positive relations with the local community from the outset is also a valuable, though often overlooked, step.

From Blueprint to Reality: Your Next Steps

Selecting the right site is a foundational step that will influence the long-term success of your solar manufacturing venture in Nicaragua. The decision requires a careful balance of logistical practicality, infrastructural reliability, and financial strategy. By prioritizing a location with robust utility connections and leveraging the substantial benefits of the country’s Free Trade Zones, an entrepreneur can build a resilient and competitive operation.

For business professionals planning their entry into this market, structured guidance can help mitigate the risks of these critical early-stage decisions. Platforms like pvknowhow.com provide educational resources and frameworks designed to support investors through each phase of establishing a solar factory.