Imagine a newly established solar module factory in South Africa, its production lines running and pallets of finished modules ready for shipment. Yet, a critical oversight prevents them from being sold or installed anywhere in the country. The modules, though perfectly functional, lack the mandatory certifications required for legal market access.

This scenario highlights a crucial reality for any entrepreneur in this sector: product certification isn’t just an optional quality seal, but a fundamental prerequisite for doing business.

For manufacturers in South Africa, successfully navigating the approvals process for the South African Bureau of Standards (SABS) and the International Electrotechnical Commission (IEC) is a critical step. This guide outlines the process, costs, and strategic importance of securing these certifications to ensure your products can compete both locally and internationally.

Understanding the Key Certifications: SABS and IEC

At the core of solar module quality assurance lie two main bodies of standards. While they work in tandem, they serve distinct roles.

The International Benchmark: IEC Standards

The International Electrotechnical Commission (IEC) develops global standards for a vast range of electrical and electronic technologies, including photovoltaics. For solar modules, two standards are paramount:

IEC 61215 (Terrestrial photovoltaic (PV) modules – Design qualification and type approval): This standard tests the design and performance of a solar module. It subjects modules to a battery of stress tests, including thermal cycling, humidity-freeze tests, and mechanical load tests, to ensure they can withstand decades of outdoor exposure.

IEC 61730 (PV module safety qualification): This standard focuses on safety, assessing a module’s construction to protect against electrical shock, fire hazards, and personal injury. It ensures the product is safe for installers, firefighters, and end-users over its entire lifespan.

Obtaining IEC certification signifies that a module meets internationally recognized benchmarks for quality, performance, and safety.

The National Gatekeeper: SABS Approval

The South African Bureau of Standards (SABS) is the national body responsible for developing and maintaining standards to ensure product quality and safety in the country. In the solar industry, SABS largely adopts IEC standards, publishing them as national standards with a ‘SANS’ prefix (e.g., SANS 61215 and SANS 61730).

For a solar module to be sold legally in South Africa, it must have SABS approval, which confirms its compliance with these national standards. This process involves testing at SABS-accredited laboratories (the ‘A-Lab Programme’) and factory inspections.

The Legal Framework: Why Certification is Mandatory

The requirement for certification is not merely a recommendation; it is legally enforced by the National Regulator for Compulsory Specifications (NRCS). The NRCS maintains a compulsory specification for electrical and electronic apparatus, VC 8055, which mandates that solar modules sold in South Africa must comply with SANS/IEC 61730 for safety.

Without a valid SABS Mark of Approval and the associated NRCS Letter of Authority (LoA), a manufacturer cannot legally sell their modules in South Africa. Attempting to do so can result in confiscated products, fines, and significant reputational damage. This makes understanding the certification process a critical part of learning how to start a solar panel manufacturing business.

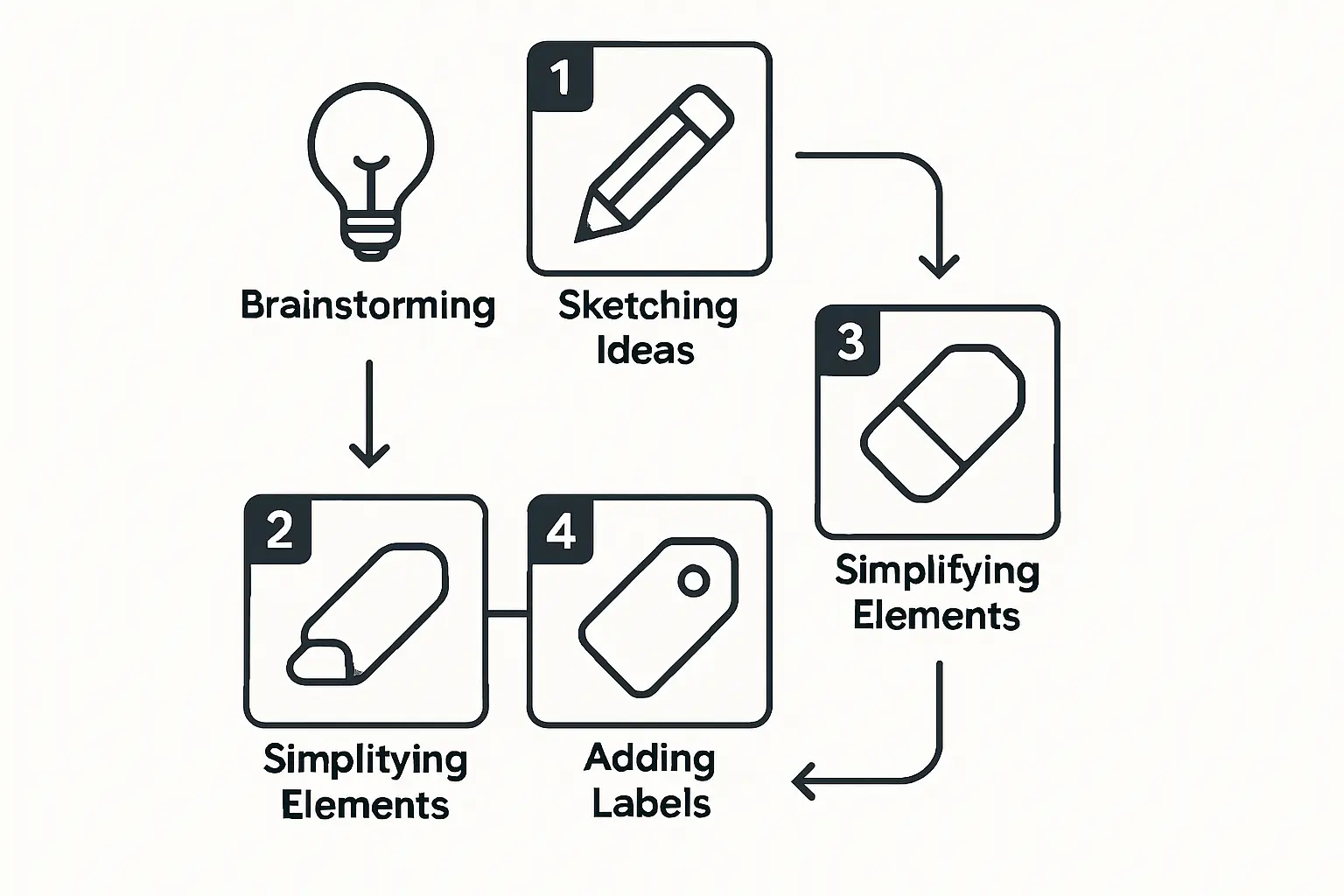

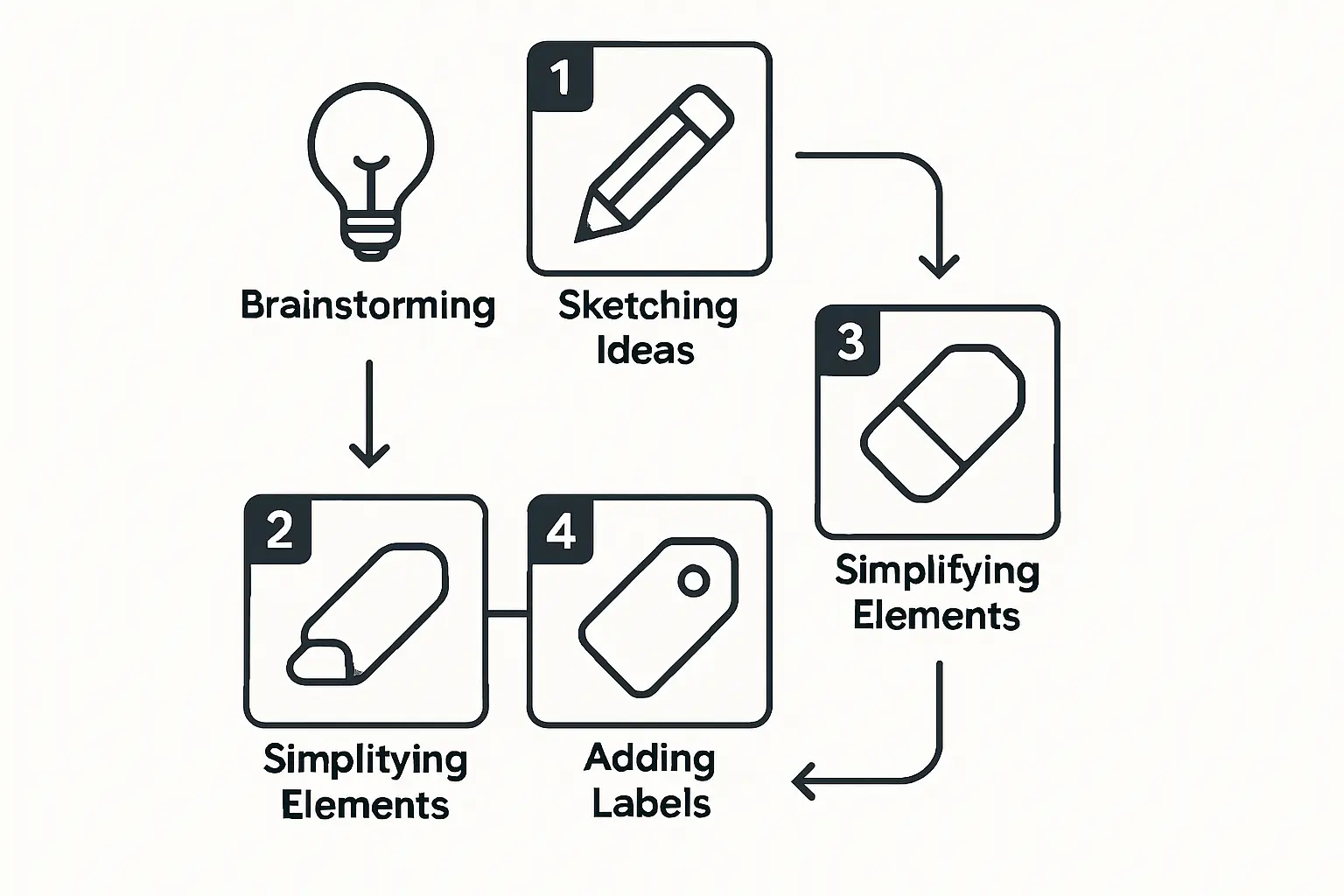

The Step-by-Step Certification Process

The journey from a finished product to a certified, market-ready module follows a structured and rigorous path. While specifics can vary, the typical process involves several key stages.

1. Factory Readiness and Quality Management

Before an application is even submitted, the factory must be prepared. This includes implementing a Quality Management System (QMS) like ISO 9001 to ensure production processes are documented, consistent, and traceable.

All manufacturing and testing equipment must be properly calibrated to guarantee consistent output. The quality of your production line, detailed in a solar panel manufacturing machine list, directly impacts your ability to pass certification.

Furthermore, the exact components used in the module (cells, glass, backsheet, junction box, etc.) must be clearly defined in a Bill of Materials (BOM) and controlled, as the certification applies to this specific construction.

2. Application and Documentation Submission

The manufacturer formally applies to a certification body, typically SABS for the national mark. This involves submitting extensive documentation, including the module’s technical specifications, the BOM, manufacturing process details, and QMS records.

3. The Factory Audit

Inspectors from the certification body will conduct an on-site audit of the manufacturing facility. They verify that the documented QMS is being followed in practice, check equipment calibration records, and ensure the production environment can consistently produce modules that match the certified design.

4. Sample Selection and Testing

During the audit, the inspector will randomly select a set of sample modules directly from the production line or warehouse. These samples are then sent to an accredited laboratory for testing against the IEC 61215 and IEC 61730 standards. This practice prevents manufacturers from submitting specially prepared ‘golden samples.’

The testing phase is the most time-consuming part of the process, as modules undergo weeks or even months of environmental and mechanical stress tests.

5. Review and Granting of Certification

Once testing is complete and the factory has passed its audit, the certification body reviews all reports. If everything is in order, the certificate is issued. The manufacturer can then apply the SABS Mark to its products and, with this certificate in hand, apply for the NRCS Letter of Authority.

Budgeting and Timelines: Practical Business Considerations

Entrepreneurs must account for the significant time and financial investment required for certification. These factors should be included in any robust solar panel manufacturing business plan.

Timeline: The entire process, from application to final certification, can take between 6 and 12 months. Delays can occur if a module fails a test or if non-conformities are found during the factory audit.

Costs: The financial investment is substantial. Testing and certification costs can be anywhere from EUR 25,000 to EUR 50,000 per module family (a group of modules with similar construction but different power outputs). This figure does not include the costs of the factory audit, annual license fees to maintain certification, or the internal costs of running a quality management system.

Based on experience from J.v.G. turnkey projects, underestimating these costs and timelines is a common pitfall for new entrants. It is essential to budget for certification as a core operational expense from the very beginning.

Frequently Asked Questions (FAQ)

What is the difference between SABS and IEC certification?

IEC develops the international standards. SABS adopts these standards for South Africa and provides the national certification (the SABS Mark) that is legally required for market access within the country. An IEC certificate from an international lab is often the basis for obtaining the SABS Mark but is not a substitute for it.

Is certification a one-time process?

No. To maintain the SABS Mark, manufacturers must undergo annual surveillance audits of their factory. The certification body will also periodically re-test modules to ensure that quality has not changed over time.

Can I change a component in my module after it is certified?

Any change to a critical component in the Bill of Materials (e.g., switching to a different brand of backsheet or junction box) requires a re-evaluation or, in some cases, a partial or full re-certification. This is because the original tests were performed on a specific combination of materials.

What happens if a module fails a test?

If a module fails any part of the testing protocol, the manufacturer is notified. They must then identify the root cause, implement corrective actions in the design or production process, and resubmit new samples for testing. This can lead to significant delays and additional costs.

Certification as a Foundation for Success

Securing SABS and IEC certification is more than a regulatory hurdle; it is a strategic investment in your brand’s credibility and a non-negotiable ticket to market entry in South Africa. It demonstrates a commitment to quality, safety, and long-term performance that builds trust with distributors, installers, and financiers.

By understanding the process, planning for the associated costs and timelines, and embedding a culture of quality into your manufacturing operations from day one, you lay the essential groundwork for a sustainable and successful solar module business.