Many entrepreneurs entering the solar manufacturing sector focus intensely on machinery specifications and factory layouts. While these elements are critical, the long-term success of an assembly plant hinges on the quality and training of its technical workforce.

For investors considering the Dakar region, understanding the local labor market isn’t just an operational detail—it’s a strategic necessity. This article outlines a practical approach to sourcing, training, and retaining skilled technical staff for a solar panel assembly line in Senegal, examining local educational institutions, providing typical wage benchmarks, and offering a structured framework for developing a competent production team.

The Labor Landscape in Senegal: Opportunities and Challenges

Senegal’s economic environment presents industrial investors with both distinct opportunities and important considerations. As part of President Macky Sall’s ‘Plan Sénégal Émergent,’ the government’s strategic focus on vocational training has expanded the pool of technically skilled young people, creating a favorable climate for sourcing entry-level talent.

However, new solar ventures should anticipate a competitive landscape. The burgeoning oil and gas sector actively recruits from the same talent pool, which can drive up wage expectations for experienced technicians and engineers.

Daily logistics in Dakar, such as traffic congestion, can also affect employee commute times and require thoughtful planning around shift changes and punctuality. A successful human resources strategy needs to account for these local realities from the outset.

Identifying Talent: Key Educational Institutions in the Dakar Region

The foundation of a strong technical team is effective recruitment. Fortunately, the Dakar region is home to several reputable institutions that produce graduates with the foundational skills needed for solar module assembly.

Key institutions for sourcing talent include:

-

École Supérieure Polytechnique (ESP) de Dakar: A leading institution for engineering talent. Graduates from its electrical and mechanical engineering programs are ideal candidates for supervisory, quality control, and maintenance engineering roles.

-

Centre de Formation Professionnelle et Technique (CFPT) Sénégal-Japon: Known for its emphasis on practical, hands-on training, the CFPT graduates technicians who are well-prepared for the demands of a factory floor. Their training is well-suited for machine operation and assembly line work.

-

Lycée Technique Industriel Delafosse: This technical high school provides a solid foundation in industrial skills. Its graduates are often excellent candidates for entry-level operator positions, bringing a strong technical aptitude that can be refined through specialized in-house training.

A targeted recruitment strategy focused on these institutions can build a strong pipeline of candidates with the right technical aptitude and educational background.

Establishing a Competitive Wage Structure

Attracting and retaining qualified staff requires a competitive compensation package. While salaries fluctuate based on experience and market demand, the following figures (based on data from the early 2020s) provide a realistic baseline for financial planning.

-

Entry-Level Technician / Operator (0-2 years experience): 100,000–150,000 XOF per month.

-

Technician (2-5 years experience): 200,000–350,000 XOF per month.

-

Senior Technician / Line Supervisor: 400,000–600,000 XOF per month.

These figures should be viewed as starting points. As a new facility establishes itself and competition from other industries intensifies, these wages will likely need adjustment. Factoring in appropriate labor costs is a crucial component when calculating the overall initial investment costs for a new plant.

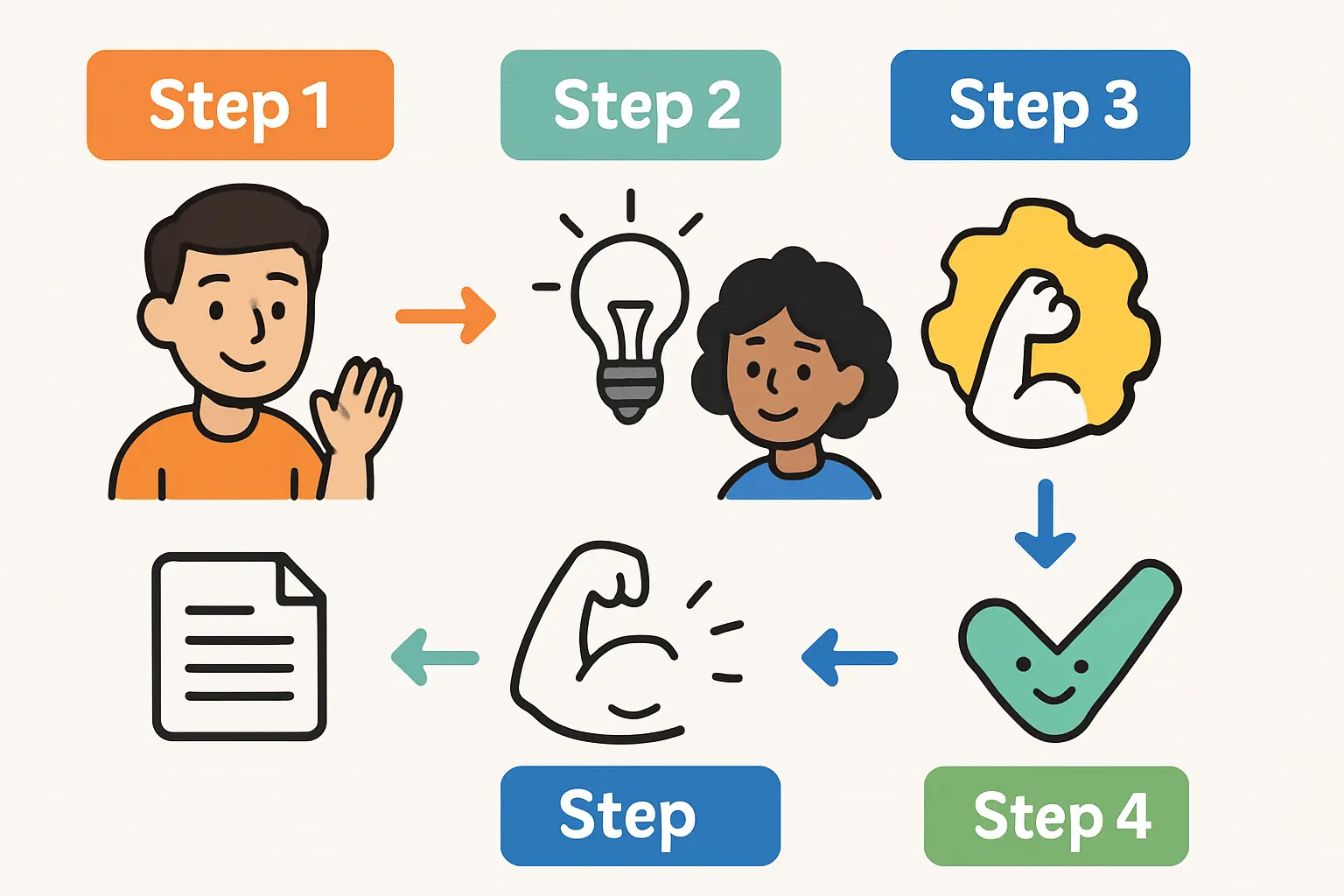

A Framework for Effective Workforce Training

For most production line roles, prior experience in solar manufacturing isn’t required. A robust, structured training program is far more valuable for ensuring high standards of quality and efficiency. Based on experience from J.v.G. Technology GmbH turnkey projects, a phased training approach has proven highly effective.

Phase 1: Classroom Instruction (2–4 weeks)

This initial phase focuses on foundational knowledge, conducted away from the production line to ensure full comprehension without the pressure of meeting production targets. Core topics include workplace safety protocols, fundamentals of photovoltaic (PV) technology, an introduction to the manufacturing process, and the principles of quality control. The objective is to ensure all new hires share a consistent theoretical understanding before they handle any equipment or materials.

Phase 2: On-the-Job Training (OJT) (8–12 weeks)

Following classroom instruction, trainees move to the factory floor under the direct supervision of experienced trainers or senior technicians. Trainees begin by shadowing experienced operators at each station (e.g., stringer, laminator, framer). They then progress to performing tasks with direct supervision, gradually taking on more independence as they demonstrate competence. This phase aims to build practical, hands-on skills and familiarize the team with the facility’s specific machinery and processes.

Phase 3: Specialized Skill Development

Certain roles demand more advanced training. Quality control staff require in-depth training on material inspection, electroluminescence (EL) and ‘sun simulator’ testing, and identifying production defects. Developing robust quality control processes is essential for market acceptance. The maintenance team requires specialized training from machine suppliers to handle troubleshooting, preventative maintenance, and repairs.

This systematic approach transforms individuals with general technical aptitude into a skilled, cohesive production team capable of manufacturing high-quality solar modules.

Integrating Local Culture with Factory Operations

Senegal has a strong apprenticeship culture where learning-by-doing is highly valued. The On-the-Job Training (OJT) model aligns perfectly with this cultural norm, making it a natural and effective method for skill transfer.

It is also important to remember that French is the official language of business and technical education in Senegal. All training materials, safety signage, and operational manuals should be in French to ensure clarity and comprehension.

This careful consideration of both workforce development and cultural context is a cornerstone of comprehensive labor and supply chain planning.

Frequently Asked Questions (FAQ)

What is the ideal background for a production line operator?

An ideal candidate has a technical diploma from a vocational school and demonstrates good manual dexterity, a strong attention to detail, and the capacity for focused, repetitive work.

How many employees are needed for a small-scale (20–50 MW) assembly line?

A typical semi-automated line of this capacity requires 25 to 30 employees per shift to cover all production, quality control, and logistical roles.

Is it necessary for new hires to have prior experience in the solar industry?

For general operator positions, no. A well-designed training program can effectively equip individuals from other technical fields with the specific skills needed for solar module assembly. For key roles like a production manager or lead quality engineer, however, prior experience is highly beneficial.

How does workforce training impact the overall project timeline?

The training period should be factored directly into the project plan. The OJT phase often runs concurrently with the commissioning and ramp-up of the production line, forming a critical part of the transition to full commercial operation in a turnkey solar factory setup.

By tapping into Dakar’s educational infrastructure and implementing a rigorous training program, entrepreneurs can build a world-class technical workforce. This investment in human capital is fundamental to achieving sustainable, high-quality solar panel production in the region.