Thailand’s Eastern Economic Corridor: A Guide for Solar Manufacturing

For entrepreneurs entering the solar manufacturing industry, the choice of location is one of the most consequential decisions they will make. It dictates not only initial setup costs and operational efficiency but also long-term access to markets, supply chains, and talent. While many regions compete for investment, Thailand’s Eastern Economic Corridor (EEC) has emerged as a purpose-built hub that warrants serious consideration.

This analysis examines the specific advantages the EEC offers for establishing a solar module production facility. It provides a framework for evaluating the corridor’s regulatory, infrastructural, and logistical merits, helping business leaders determine if this strategic zone aligns with their long-term vision.

Understanding the Eastern Economic Corridor (EEC)

The Eastern Economic Corridor is a flagship development project of the Thai government, spanning three provinces: Chachoengsao, Chonburi, and Rayong. It is not merely an industrial zone but a comprehensive ecosystem designed to propel Thailand into a high-income nation by attracting investment in targeted high-tech industries.

For solar module manufacturers, the EEC’s focus on advanced manufacturing, renewable energy, and logistics creates a powerful strategic fit. The government’s commitment to developing this area translates into tangible benefits that directly address the primary challenges of setting up a new production line, from bureaucratic hurdles to supply chain complexities.

Key Advantages for Solar Module Production in the EEC

An evaluation of the EEC reveals several core strengths highly relevant for capital-intensive industries like solar panel manufacturing.

1. A Favorable Regulatory and Investment Framework

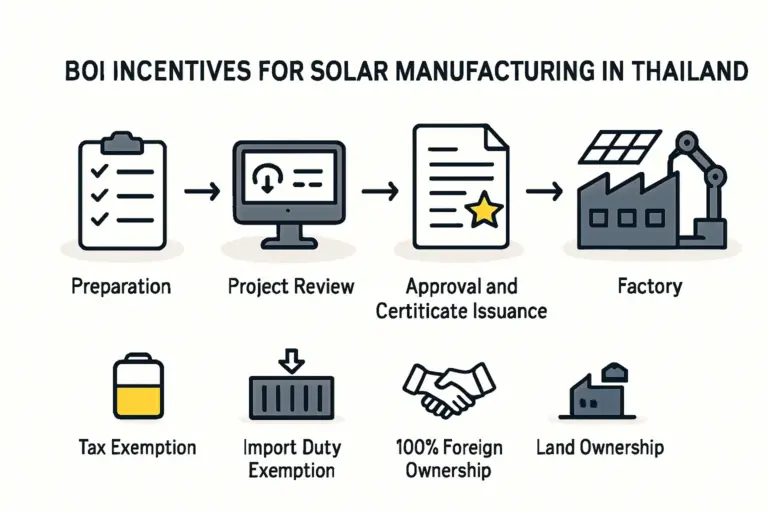

Navigating the legal and financial landscape of a new country is a primary concern for any investor. Thailand’s Board of Investment (BOI) has established a highly competitive incentive package specifically for businesses operating within the EEC.

Key incentives include:

-

Corporate Income Tax Exemptions: Eligible businesses can receive corporate income tax waivers for up to 13 years, significantly improving the financial viability of a new venture during its critical early stages.

-

Exemption on Import Duties: Exemption from import duties on machinery, raw materials, and components directly lowers both capital expenditure and ongoing operational costs—a crucial advantage for a manufacturing process reliant on imported goods.

-

Simplified Administrative Processes: The EEC offers a ‘one-stop service’ center to streamline applications for visas and work permits for foreign specialists, executives, and their families, reducing administrative friction.

-

Land Ownership Rights: Foreign investors are granted the right to lease land for 50 years, with an option for a 49-year renewal, providing the long-term security necessary for a major factory investment.

These policies signal a clear government commitment to de-risking investment and creating a stable, predictable environment for business operations.

2. World-Class Infrastructure and Logistics

A manufacturing operation’s efficiency fundamentally depends on the quality of its surrounding infrastructure. The EEC has been the focus of massive state investment to create a seamless, multi-modal logistics network. For a solar module factory, which handles both the import of bulky raw materials and the export of finished products, this network is a decisive factor.

-

Maritime Connectivity: The region is served by two world-class ports.

-

Laem Chabang Port: As one of the largest deep-sea ports in the world, it is equipped to handle the massive container ships central to the global solar supply chain. Its efficiency is critical for importing materials like solar glass, EVA foil, and aluminum frames, and for exporting finished modules to international markets.

-

Map Ta Phut Industrial Port: This port specializes in handling liquid and bulk cargo, supporting the broader industrial ecosystem in the region.

-

Aviation and Rail Links: The region’s connectivity is further enhanced by the ongoing development of U-Tapao International Airport into a major aviation hub, connected by high-speed rail to Bangkok’s Suvarnabhumi and Don Mueang airports. This facilitates executive travel, urgent freight, and integration with global business centers.

This integrated system ensures that raw materials arrive on time and finished products can be shipped efficiently, minimizing costly delays and bolstering the entire operation’s reliability.

3. Access to a Skilled Workforce and Technical Ecosystem

A modern solar factory relies heavily on automation and skilled technicians. The EEC’s development plan emphasizes creating a workforce proficient in automation, robotics, and advanced engineering.

The proximity to technical universities and vocational training centers in the region creates a sustainable talent pipeline. This helps ensure that a new factory can recruit qualified staff, from line operators to quality control engineers. For investors from outside the solar industry, having access to a pool of technically competent local staff is a significant operational advantage.

4. A Strategic Position in the Global Supply Chain

Thailand’s geographical location at the heart of the ASEAN region provides a strategic springboard into some of the world’s fastest-growing solar markets. Establishing a manufacturing base in the EEC allows a company to serve not only the domestic Thai market but also to export efficiently to Vietnam, Malaysia, Indonesia, and beyond.

Furthermore, diversifying manufacturing locations has become a key strategic priority for the global solar industry. By setting up in Thailand, a company can mitigate risks associated with geopolitical tensions and supply chain disruptions concentrated in any one region.

Practical Considerations for Establishing a Factory in the EEC

While the macro-level advantages are clear, a successful project requires detailed on-the-ground planning. J.v.G. Technology’s experience setting up turnkey production lines globally shows that navigating local regulations and infrastructure is a critical phase where structured guidance is invaluable.

Entrepreneurs considering the EEC should focus on site-specific due diligence. This includes assessing the reliability of the local power grid, water supply, and road access to the chosen plot of land. While the overall infrastructure is excellent, conditions can vary between specific industrial estates.

Starting a solar panel manufacturing business in a new country can seem complex, but the structured environment of the EEC is designed to simplify it. With proper planning and local expertise, a new production line can become operational in a surprisingly efficient timeframe.

Frequently Asked Questions (FAQ)

What is the typical investment for a small-to-medium solar factory in the EEC?

While costs vary based on automation levels and capacity, a 50-100 MW per year facility typically requires an initial investment in machinery and setup in the range of several million US dollars. The BOI incentives can significantly reduce this initial outlay.

Is it difficult for foreign companies to operate in the EEC?

The EEC is specifically designed to be foreign-investor friendly. The long-term land leasehold rights and the one-stop service for administrative matters help make the process as straightforward as possible for international companies.

How does the EEC compare to other manufacturing hubs in Southeast Asia?

Each country has its advantages. The EEC’s unique proposition lies in its powerful combination of targeted, high-value incentives, newly developed world-class infrastructure, and a clear governmental strategy focused on high-tech industries like solar.

What are the main challenges to consider?

Potential challenges include navigating cultural and language differences and securing the right local partners for construction and logistics. However, these are common to any international venture and can be managed effectively with experienced advisors.

Conclusion: Making an Informed Decision

Thailand’s Eastern Economic Corridor presents a compelling and strategic option for entrepreneurs and businesses looking to establish a solar module manufacturing facility. The combination of strong government support, exceptional logistics, attractive financial incentives, and a growing talent pool creates a powerful ecosystem for success.

For business leaders exploring this path, the next step is to translate this strategic opportunity into a concrete business plan by developing a detailed financial model and a site-specific feasibility study.