An investor considering a new solar module factory often begins by analyzing macroeconomic data: GDP growth, foreign investment policies, and general labor costs. In Vietnam, these indicators are overwhelmingly positive. But a modern factory producing high-efficiency PERC or TOPCon modules requires more than an available workforce—it demands a technically proficient one. The critical question shifts from ‘Are workers available?’ to ‘Are the right engineers and technicians available?’

This analysis goes beyond surface-level statistics to examine the specific competencies within Vietnam’s labor pool. It explores whether the country’s educational framework and industrial experience can meet the technical demands of a sophisticated, automated solar production facility.

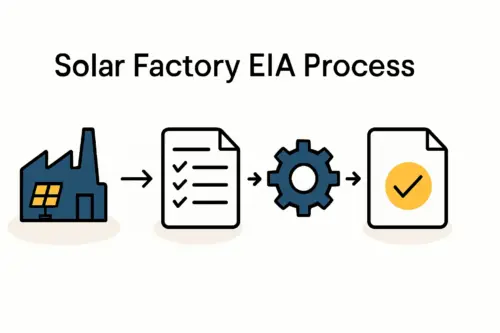

The Shifting Landscape: Why General Labor is No Longer Enough

The solar manufacturing industry has undergone a significant technological evolution. Early production lines for standard BSF (Back Surface Field) modules were heavily reliant on manual processes. Today, a competitive solar production line is a showcase of automation and precision engineering, especially when manufacturing advanced cell technologies like PERC (Passivated Emitter and Rear Cell) and TOPCon (Tunnel Oxide Passivated Contact).

This technological shift has profound implications for staffing:

-

Process Control: High-efficiency modules are sensitive to minute variations in temperature, chemical concentrations, and handling. This requires engineers who understand materials science and statistical process control, not just line supervisors.

-

Automation and Robotics: Modern stringers, laminators, and testing equipment are complex automated systems. The factory needs technicians who can operate, maintain, and troubleshoot robotics and PLC (Programmable Logic Controller) systems.

-

Data Analysis: Manufacturing execution systems (MES) generate vast amounts of data. Interpreting this data to optimize yield, improve quality, and reduce waste has become a key engineering function.

Value is no longer created by manual assembly but by the precise management of advanced, automated processes. This reality makes a well-educated technical team essential.

Analyzing Vietnam’s Technical Education and Workforce

An assessment of Vietnam’s capacity to meet these demands reveals a strong foundation, though investors will need to strategically develop specific areas.

A Strong Foundation in STEM Education

Vietnam has consistently demonstrated a strong educational aptitude in core technical fields. According to the World Bank, the country’s PISA scores, which measure secondary school students’ abilities, are consistently high in science and mathematics, often outperforming many OECD countries. This indicates a large pool of young talent with the fundamental analytical skills required for engineering and technical roles.

Ready to make big Profits?

The solar Industry is Booming

WE HELP NEWCOMERS to the solar industry start their own solar module production line. Customers can make BIG PROFITS by selling modules and finding investors, without wasting money and time on things they don't need!

Government data shows that Vietnamese universities graduate over 100,000 students in engineering and technology disciplines each year, creating a steady stream of candidates with foundational knowledge in mechanics, electronics, and materials science.

The Vocational Training Advantage

Beyond university-level education, Vietnam has a robust Vocational Education and Training (VET) system. These institutions produce approximately 2 million graduates annually who specialize in hands-on technical skills. This creates a critical pipeline of talent for roles such as:

-

Machine Operators: Individuals trained to operate sophisticated industrial equipment.

-

Maintenance Technicians: Skilled personnel capable of performing preventative maintenance and basic repairs on automated machinery.

-

Quality Assurance Inspectors: Staff with training in measurement, inspection protocols, and quality standards.

This VET system is a key asset, providing the hands-on workforce essential to keeping a modern factory running efficiently.

Challenges in Advanced Manufacturing Experience

While the educational foundation is strong, the primary challenge lies in the relative scarcity of direct experience with the latest PV technologies. Because the global shift to TOPCon is recent, few engineers or technicians in Vietnam will have direct, hands-on experience with the specific nuances of its manufacturing process.

This ‘experience gap’ is not a barrier but a factor that must be incorporated into the project plan. It underscores the need for a structured, comprehensive training program during the factory’s commissioning phase. Based on experience from J.v.G. turnkey projects, a well-designed knowledge transfer plan can bridge this gap effectively within a matter of months.

Key Roles and Skill Requirements for a Modern Solar Factory

A closer look at the key technical roles in a modern facility reveals the specific labor requirements.

Process Engineers

These individuals are the technical heart of the operation. They are responsible for optimizing each stage of production, from cell stringing and lamination to junction box application. A successful process engineer for a PERC or TOPCon line typically has a background in chemical engineering, materials science, or mechanical engineering. Their primary focus is on maximizing production yield and ensuring the final product meets performance specifications.

Quality Control (QC) Technicians

With high-efficiency modules, quality control is paramount. QC technicians operate sophisticated testing equipment, including sun simulators for power measurement and electroluminescence (EL) testers for detecting microcracks and other cell defects. Proficiency with EL testing in solar modules is a non-negotiable skill for ensuring long-term module reliability and bankability. These roles require meticulous attention to detail and an understanding of statistical quality control methods.

Maintenance and Automation Specialists

In a highly automated factory, uptime is directly tied to the skill of the maintenance team. These specialists must be proficient in troubleshooting and servicing robotic systems, conveyor belts, and automated laminators. Expertise in PLCs is particularly valuable, as these controllers manage the logic and sequencing of nearly all machinery on the production floor. A strong maintenance team prevents costly downtime and ensures a consistent production flow.

Strategic Considerations for Building a Technical Team in Vietnam

For an investor entering the market, successfully assembling a world-class technical team in Vietnam requires a strategic approach.

The ‘Train-the-Trainer’ Model

A highly effective strategy is the ‘train-the-trainer’ model. This involves bringing in a small team of external experts during the factory setup and commissioning phase. These experts work closely with a core group of locally hired Vietnamese engineers and lead technicians. They transfer not just operational knowledge but also the underlying principles of process control and troubleshooting. This core local team then becomes the internal training resource for the rest of the workforce, ensuring knowledge becomes embedded within the organization.

Partnering with Local Universities and VET Centers

Forward-thinking companies can build a sustainable talent pipeline by establishing relationships with local universities and vocational schools. Offering internships, sponsoring final-year projects, or collaborating on curriculum development can give a company priority access to the best emerging talent. This proactive approach mitigates future hiring challenges and builds a strong local reputation.

Competitive Compensation and Professional Culture

While Vietnam’s labor market is cost-competitive, skilled technical professionals are in high demand across various manufacturing sectors. To attract and retain top talent, offering a competitive compensation package is essential. Equally important is a professional work environment with clear paths for career advancement and ongoing training.

Frequently Asked Questions (FAQ)

What is the typical salary range for a solar process engineer in Vietnam?

While salaries vary based on experience and location (e.g., Ho Chi Minh City vs. a provincial area), a junior engineer with a relevant degree might expect a starting salary in the range of $800–$1,200 USD per month. A senior engineer with significant manufacturing experience could command $2,000 USD or more. These figures are competitive and allow for a highly skilled team to be built at a manageable operational cost.

How long does it take to train a new team for a TOPCon production line?

With a structured training program led by experienced experts, a core team of local engineers and technicians can achieve operational proficiency within 3 to 6 months. This period typically covers equipment commissioning, process stabilization, and quality control protocols. The broader workforce of operators can be trained by this core team in a shorter timeframe, often within 4 to 8 weeks.

Is the language barrier a significant issue for foreign management?

English proficiency is increasingly common among university-educated engineers in Vietnam. However, on the factory floor with technicians and operators, Vietnamese will be the primary language. It is standard practice and highly recommended for foreign-led projects to employ bilingual local managers or dedicated translators to ensure clear communication and avoid misunderstandings.

Can a factory be run successfully without prior solar experience in the local team?

It is challenging but entirely possible. Success hinges on two factors: hiring a team with strong foundational skills in engineering and manufacturing, and implementing a comprehensive knowledge transfer plan from an experienced technical partner. The aptitude for learning complex processes is readily available in the Vietnamese workforce—the key is providing the specialized knowledge required for solar manufacturing.

Conclusion

Vietnam presents a compelling case for establishing an advanced solar module factory. Its labor pool is built on a strong educational foundation in science and technology. For the investor, the task is not to find talent but to strategically develop it. By pairing this inherent potential with expert training and a well-planned operational structure, a company can assemble a highly skilled and cost-effective technical team. This creates a powerful competitive advantage in the global solar market.