Many entrepreneurs entering the solar industry focus on the final product: the solar module. They often assume the environmental benefit begins only when the panel is installed. However, a significant part of a solar panel’s lifecycle impact is shaped long before it sees the sun—during manufacturing.

The production of core components like polysilicon, ingots, and wafers is extraordinarily energy-intensive. This presents both a challenge and an opportunity.

For businesses aiming to build a truly sustainable and cost-competitive manufacturing operation, the source and cost of electricity are not minor details; they are foundational to success. This analysis explores how Sweden’s unique energy profile, dominated by low-carbon hydropower, offers a distinct competitive advantage for these critical, energy-heavy stages of PV manufacturing.

The Overlooked Factor: Energy in PV Component Manufacturing

The journey from raw silicon to a finished solar cell involves several demanding stages, with the initial steps consuming the most energy.

-

Polysilicon Production: Refining metallurgical-grade silicon into the high-purity polysilicon required for solar cells is an intensive process, often involving temperatures exceeding 1,000°C.

-

Ingot Pulling: Polysilicon is melted and slowly drawn into large cylindrical or rectangular crystals, known as ingots. This process, which can take several days per ingot, requires a constant, substantial, and stable supply of electricity to maintain precise temperature controls.

-

Wafer Slicing: The ingots are then sliced into ultra-thin wafers using diamond-wire saws, another continuous process where electricity is a primary operational expense.

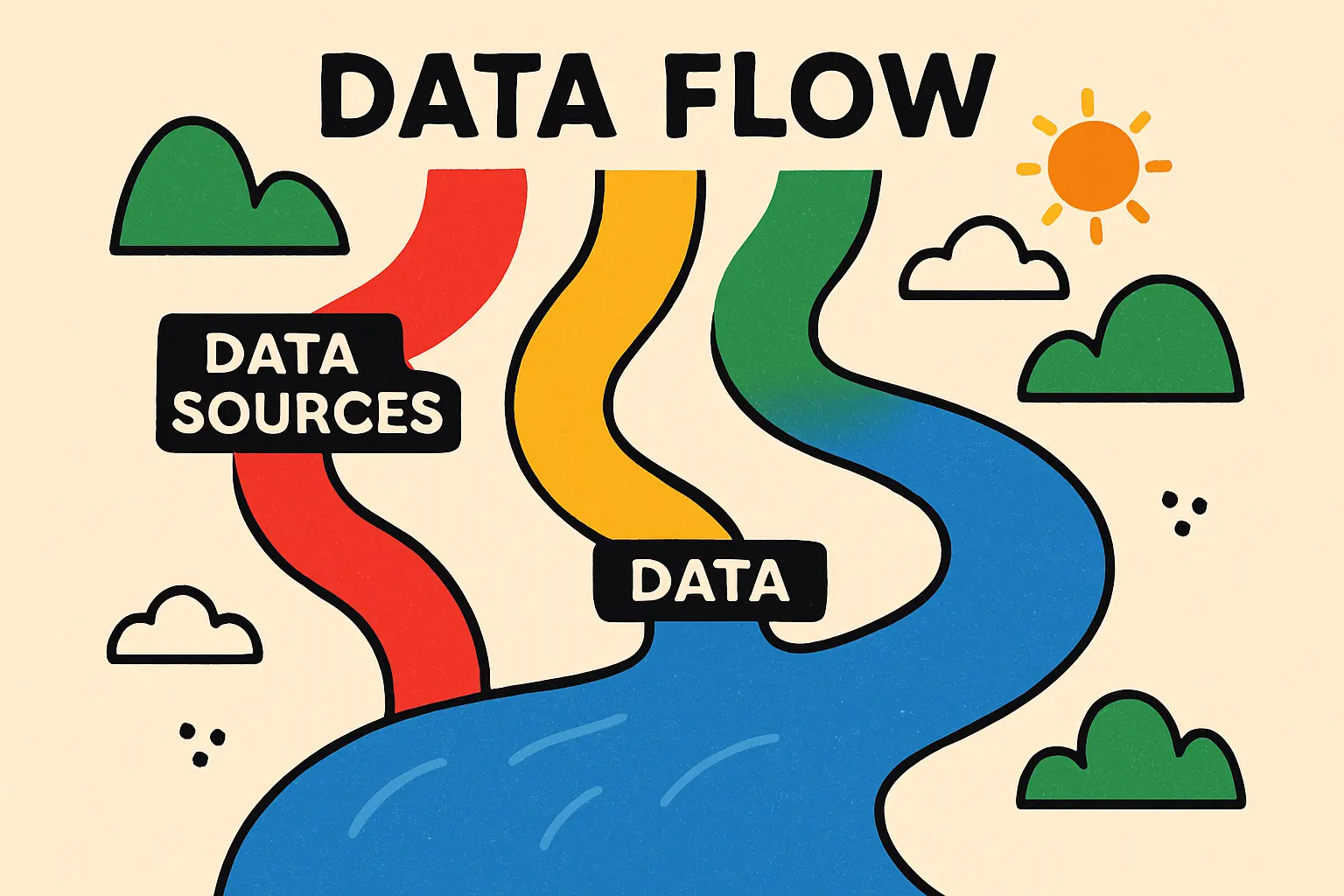

In many traditional manufacturing hubs, this energy comes from fossil fuels, primarily coal. This creates two major business problems: volatile, often high electricity costs, and a significant ’embedded’ carbon footprint in the final product.

Understanding the Cost Structure

For a typical ingot and wafer production facility, electricity makes up a substantial portion of total operational expenditure (OPEX). Industry analyses show that energy can account for 20% to 30% of the cost of goods sold (COGS) for wafer production. A fluctuation of just a few cents per kilowatt-hour (kWh) can mean the difference between profitability and loss.

This dependency leaves manufacturers vulnerable to global energy price shocks and regional grid instability, creating significant business risk.

Sweden’s Energy Profile: Stability, Low Cost, and Low Carbon

Sweden presents a compelling alternative, built on a foundation of abundant and reliable hydropower. The country’s energy infrastructure offers a unique combination of factors that directly addresses the core challenges of energy-intensive manufacturing.

A Fossil-Free Foundation

Sweden’s electricity generation is overwhelmingly fossil-free. The energy mix consists primarily of:

- Hydropower: Approximately 45%

- Nuclear Power: Approximately 30%

- Wind Power: Approximately 17%

This composition means electricity used for industrial processes has one of the lowest carbon footprints in the world. For a solar manufacturer, this is more than an environmental benefit—it’s a powerful marketing and ESG (Environmental, Social, and Governance) advantage. A solar panel produced with Swedish hydropower starts its life with a much smaller carbon debt to repay.

Competitive and Stable Electricity Prices

Historically, Sweden has enjoyed some of the most competitive electricity prices in Europe. While prices fluctuate, the strong hydropower base provides a stabilizing effect not seen in markets heavily reliant on natural gas or other fossil fuels.

This predictability is invaluable for long-term financial planning, allowing businesses to forecast energy costs with greater certainty and maintain a competitive edge. J.v.G. Technology GmbH’s experience in planning turnkey factories shows that a stable, low-cost energy supply is often a decisive factor in selecting a location. Over the long term, savings on operational costs can significantly outweigh potentially higher initial setup or labor costs.

Translating Energy Advantages into Business Advantages

For an entrepreneur or investor, these characteristics translate into tangible competitive benefits when producing components like ingots, wafers, or cells.

1. Lower Operational Expenditure (OPEX)

The most direct benefit is a reduction in production costs. A lower price per kWh flows directly to the bottom line, enhancing profit margins. In an industry where price competition is fierce, a structural cost advantage in energy can be a game-changer, allowing a manufacturer to be more resilient during market downturns.

2. A ‘Greener’ Product with a Lower Carbon Footprint

A solar panel’s ‘Energy Payback Time’ (EPBT) is the time it must operate to generate the same amount of energy consumed during its production. Manufacturing with coal-powered electricity leads to a high EPBT.

By leveraging Sweden’s hydropower, a manufacturer can produce wafers and cells with a significantly lower embedded carbon footprint. This creates a premium product that is increasingly attractive to discerning customers, particularly in Europe and North America, where supply chain sustainability is a growing priority.

3. Enhanced Production Reliability

Continuous processes like crystal pulling are highly sensitive to power interruptions. A sudden loss of electricity can destroy an entire multi-million dollar ingot, leading to significant material waste and production delays. Sweden’s highly stable and reliable grid minimizes this risk, ensuring smoother, more predictable, and more efficient operations.

Frequently Asked Questions (FAQ)

What exactly are ingots and wafers?

An ingot is a large, solid crystal of high-purity silicon that serves as the raw material for solar wafers. A wafer is a very thin slice of an ingot, which forms the base for a solar cell.

Why is ingot and wafer production so energy-intensive?

The process involves melting silicon at extremely high temperatures (around 1,414°C) and maintaining that heat with precise control for several days as the crystal is formed. Slicing the hard ingot into thin wafers also requires significant, continuous energy.

Is hydropower reliable enough for 24/7 industrial manufacturing?

Yes. Hydropower is one of the most reliable forms of electricity generation. Unlike solar or wind, it is not intermittent and can provide the constant baseload power ideal for continuous industrial applications. Sweden’s extensive reservoir system ensures this reliability year-round.

How does this strategy fit within the broader investment plan?

The energy advantage is a critical component of the overall business case. While it lowers operational costs, it must be evaluated alongside other factors like labor, logistics, and initial capital. A full investment plan must consider how energy savings can offset other expenditures over the project’s life.

Conclusion: A Strategic Foundation for Future-Proof Manufacturing

Choosing a location for a solar component factory is a complex decision with long-term consequences. While factors like labor costs and logistics are important, the fundamental cost and sustainability of energy are becoming critical differentiators.

Sweden’s combination of low-cost, stable, and low-carbon hydropower offers a powerful strategic advantage for the most energy-intensive stages of PV manufacturing. It provides a foundation for lower operating costs, a more sustainable product, and greater operational stability. For the entrepreneur looking to build a resilient and future-proof business in the solar industry, this overlooked asset warrants serious consideration.