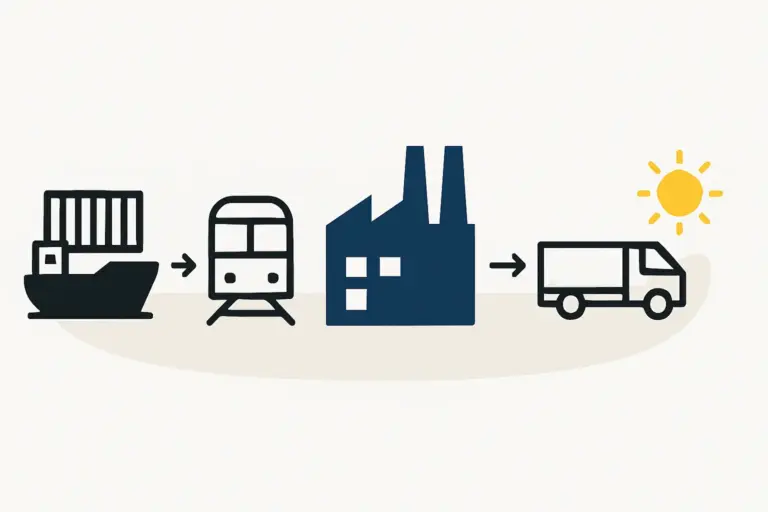

Imagine an entrepreneur has successfully financed and launched a new solar module assembly factory in the United States. Their first container of critical components arrives at the Port of Los Angeles, ready to kickstart production.

However, the shipment is flagged and detained by U.S. Customs and Border Protection (CBP). The reason? Insufficient proof that the materials are free from forced labor, as mandated by the Uyghur Forced Labor Prevention Act (UFLPA). Production halts before it even begins, and capital is tied up indefinitely.

This isn’t a hypothetical scenario. It has become a critical business reality for anyone involved in the US solar industry. The UFLPA has fundamentally reshaped supply chain strategy, transforming it from a logistical task into a core element of business risk management.

For professionals entering the solar manufacturing space, understanding this landscape isn’t just an advantage—it’s a prerequisite for success. This guide offers a clear, strategic overview of the challenges and solutions for building a transparent and compliant supply chain for a US-based solar module factory.

Understanding the UFLPA: A New Paradigm for Importers

Enacted in 2022, the Uyghur Forced Labor Prevention Act is a significant piece of trade legislation with a direct impact on the solar industry. Its core principle is a ‘rebuttable presumption’ that goods mined, produced, or manufactured wholly or in part in China’s Xinjiang Uyghur Autonomous Region (XUAR) are made with forced labor and are therefore banned from importation into the United States.

What does ‘rebuttable presumption’ mean for a business owner? It places the burden of proof squarely on the importer. Simply stating that a supply chain is clean is no longer enough; importers must provide ‘clear and convincing evidence’ to the contrary.

The solar industry is particularly affected because an estimated 45% of the world’s solar-grade polysilicon—the primary raw material for most solar cells—has historically originated from the Xinjiang region. This puts any company importing solar modules or their constituent parts under intense scrutiny.

The Core Challenge: Tracing Polysilicon from Sand to Solar Module

The primary difficulty in proving UFLPA compliance lies in the complexity and opacity of the global solar supply chain. The journey from raw material to a finished solar panel involves multiple stages, often spanning several countries and companies.

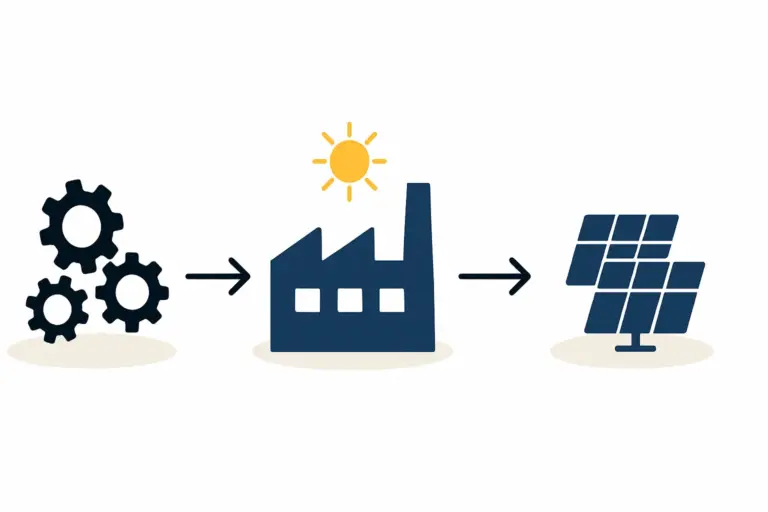

A simplified overview of the process looks like this:

- Polysilicon Production: High-purity silicon is produced from quartz sand.

- Ingot and Wafer Manufacturing: The polysilicon is melted and formed into cylindrical ingots, which are then thinly sliced into wafers.

- Solar Cell Production: The wafers are processed and converted into photovoltaic cells that can generate electricity.

- Module Assembly: Cells are interconnected, laminated between glass and a backsheet, framed, and fitted with a junction box to create the final solar module.

The problem stems from ‘commingling.’ Polysilicon from various global sources is often mixed at the ingot and wafer stage. Tracing a specific batch of polysilicon through this process is like trying to trace a single drop of water in a river. Consequently, CBP requires extensive documentation—including purchase orders, invoices, and production records from every step of the manufacturing chain—to prove the origin of the materials.

Strategic Sourcing: Building a Resilient and Compliant Supply Chain

Navigating this environment requires a proactive and meticulous strategy. Entrepreneurs cannot afford to treat supply chain management as an afterthought; it must be a foundational pillar of the business plan from day one.

1. Comprehensive Supply Chain Mapping

The first step is to achieve full transparency. This involves mapping the entire supply chain for every critical component—not just the cells, but also the glass, aluminum frames, backsheets, and junction boxes. A business must identify not only its direct Tier 1 suppliers but also the Tier 2 and Tier 3 suppliers they source materials from. This level of detail is essential to identify potential exposure to the Xinjiang region.

2. Rigorous Supplier Due Diligence

Once potential suppliers are identified, a robust due diligence process is critical. This process goes beyond simple price and quality negotiations. It requires asking specific, probing questions about their own supply chain controls. Asking the right questions, in turn, necessitates a deep understanding of the solar module manufacturing process. Effective due diligence includes:

- Detailed Questionnaires: Requiring suppliers to document their entire supply chain for the products they provide.

- Contractual Clauses: Including language in supply agreements that guarantees UFLPA compliance and allows for third-party audits.

- Third-Party Audits: Engaging independent auditors to verify supplier claims and inspect facilities and records.

3. Diversifying Sourcing to Compliant Regions

The most direct strategy to ensure compliance is to source materials, especially polysilicon, from outside the Xinjiang region. Leading manufacturers are actively securing supply chains based in other parts of the world. Key regions for UFLPA-compliant polysilicon include:

- United States: Companies like Hemlock Semiconductor and REC Silicon.

- Germany: Wacker Chemie AG is a major global producer.

- Malaysia: A significant hub for polysilicon and wafer manufacturing outside of China.

While this shift often comes with a cost premium, the added expense should be viewed as an insurance policy against the far greater costs of shipment seizures, production delays, and reputational damage.

The Business Case for Compliance: Beyond Risk Mitigation

While UFLPA compliance presents challenges, it also creates a significant business opportunity. A transparent, traceable, and compliant supply chain has quickly become a powerful competitive advantage in the US market.

The Inflation Reduction Act (IRA) provides substantial incentives for domestic solar manufacturing. As new US-based factories come online, the demand for verifiably compliant components will soar. Entrepreneurs who can guarantee a UFLPA-compliant product will be preferred suppliers for large-scale projects and discerning customers. A compliant supply chain is a cornerstone of a sound solar factory business plan.

Experience from J.v.G. turnkey projects shows that investors who address supply chain compliance early in the planning stage are better positioned for long-term success and attract more favorable financing. It demonstrates foresight and a sophisticated understanding of the market.

Frequently Asked Questions (FAQ) on UFLPA Compliance

What is the Uyghur Forced Labor Prevention Act (UFLPA)?

The UFLPA is a US law that establishes a ‘rebuttable presumption’ that any goods produced in whole or in part in the Xinjiang region of China are made with forced labor and are banned from importation. The importer bears the burden of proving otherwise.

Which solar module materials are most affected?

Polysilicon is the primary material of concern. However, the legislation also covers other materials from the region, such as quartz (used to make the crucibles for growing silicon ingots) and aluminum for frames.

What happens if a shipment is detained by Customs and Border Protection (CBP)?

If a shipment is detained, the importer is issued a Withhold Release Order (WRO). The importer then has a limited time to submit evidence to prove the goods are compliant. If the evidence is deemed insufficient, the shipment can be seized, and the importer may have to re-export or destroy the goods, resulting in significant financial loss.

Does the UFLPA apply if I am only assembling modules in the US using imported cells?

Yes. The act applies to goods ‘manufactured in whole or in part’ in the region. If the imported solar cells were produced using wafers sliced from an ingot made with Xinjiang-origin polysilicon, the final module assembled in the US would be subject to the UFLPA.

Conclusion: Your Supply Chain as a Strategic Asset

For entrepreneurs planning to establish a solar factory in the United States, supply chain strategy is no longer a peripheral concern; it is central to the viability of the entire enterprise. The UFLPA demands a new level of diligence, transparency, and strategic sourcing.

Building a fully compliant supply chain is a complex but achievable goal. It requires proactive planning, rigorous vetting of partners, and a commitment to transparency from the very beginning. An entrepreneur doesn’t need to be an expert in global trade law, but they do need a robust strategy.

By viewing the supply chain not as a cost center but as a strategic asset, a business leader can build a resilient, reputable, and profitable manufacturing operation poised to meet the growing demand for American-made solar energy. For entrepreneurs starting this journey, understanding the investment required for a solar factory is the next logical step in building a comprehensive business plan.