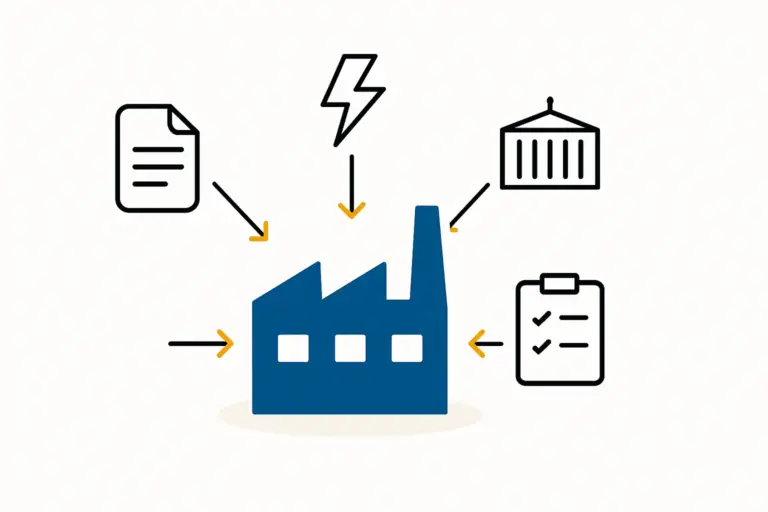

A well-structured business plan for a solar module factory often focuses on machinery, labor, and market demand. However, a frequently underestimated factor can dictate a venture’s long-term profitability: an efficient raw material supply chain.

Imagine a state-of-the-art production line sitting idle because a shipment of solar cells or EVA encapsulant is delayed for weeks at a congested port, ensnared in bureaucratic customs procedures. This single logistical bottleneck can erode margins and damage a new company’s reputation before it even produces its first module.

Through a detailed case study of the Port of Montevideo in Uruguay, this article examines the critical role of port logistics in the success of a solar module manufacturing business. Choosing the right port of entry can transform a potential vulnerability into a significant competitive advantage, particularly for entrepreneurs entering the industry. Understanding these dynamics is a fundamental part of initial planning.

The Lifeline of a Solar Factory: Securing Key Imports

A solar module assembly plant is fundamentally a conversion business, importing specialized components and assembling them into a finished product of higher value. The reliability of this import process is paramount.

Because the primary materials are typically sourced from established global suppliers, international shipping is an operational reality. These include:

- Solar Cells: The core component that converts sunlight into electricity.

- Solar Glass: Specially tempered, low-iron glass for the front surface.

- Aluminum Frames: Pre-fabricated frames that provide structural integrity.

- Encapsulant (EVA/POE): Polymer sheets that laminate and protect the solar cells.

- Backsheets or Rear Glass: The protective backing of the module.

- Junction Boxes: Electrical enclosures on the back of the module.

Any delay in receiving even one of these essential raw materials for solar panels can bring the entire production line to a halt, incurring significant daily costs without any output.

Montevideo as a Case Study in Logistical Excellence

For any planned solar manufacturing facility in the region, the Port of Montevideo stands out as a compelling logistical hub. Its operational advantages directly address the common pain points of international supply chains.

Strategic Location and Deepwater Access

Located on the Rio de la Plata estuary, Montevideo is the only natural deepwater port in the region, allowing it to accommodate the large, modern Post-Panamax container vessels that offer lower per-unit shipping costs. A facility that can receive goods from these vessels gains an immediate cost advantage over competitors reliant on smaller ports, which often require goods to be transshipped, adding time and expense.

Based on J.v.G. Technology’s experience with turnkey factory setups, analyzing a port’s physical capacity is a critical first step. A port that cannot handle the largest vessels is already placing a ceiling on future logistical efficiency and cost savings.

The ‘Free Port’ Advantage

Uruguay’s designation of the Port of Montevideo as a free port offers a significant benefit for an assembly-focused business. Key features include:

- Tax Exemption: Goods stored within the port’s designated areas are not subject to Uruguayan import taxes or duties. For a solar manufacturer, this means materials can be brought in and stored without incurring immediate tax liabilities.

- Free Circulation of Goods: Merchandise can enter and leave the port without complex customs formalities, provided it does not enter the national customs territory.

- Extended Storage: Goods can be stored for an indefinite period, allowing a manufacturer to build a buffer stock of critical components without the pressure of immediate customs clearance and payment.

This framework allows a factory to manage its inventory and cash flow with much greater flexibility, drawing materials from the port warehouse to the main factory as production schedules demand.

Operational Efficiency: Averting Costly Delays

Port congestion and slow customs clearance are two of the greatest risks to a supply chain. Montevideo has built a reputation for high efficiency, directly mitigating these risks.

- Low Congestion: The port is known for its fluid operations and minimal waiting times for vessels to berth. This contrasts sharply with other regional ports where ships can wait for days or even weeks.

- Rapid Turnaround: Data indicates typical vessel turnaround times of under 48 hours. For an importer, this predictability is invaluable for planning production schedules.

- Streamlined Customs: Uruguayan customs procedures are largely digitized and transparent. With proper documentation prepared by a competent customs broker, clearance is typically swift, reducing the risk of containers being held for manual inspection or administrative hurdles.

These efficiencies translate directly into lower operational costs and a more reliable production forecast. Both are critical for calculating the initial investment costs and ongoing working capital needs.

Inland Connectivity and Infrastructure

A port’s efficiency is only as good as its connection to the hinterland; the final leg of the journey—from port to factory floor—must be just as reliable. Montevideo offers robust connectivity through an established network of highways and rail links.

This ensures that once containers are cleared, they can be transported efficiently to a factory location within the country. Logistical planning for your factory must include mapping these inland routes and assessing their condition, capacity, and security. The proximity of a potential factory site to these main transport arteries is a key consideration.

Conclusion: Logistics as a Strategic Pillar

The success of a solar module manufacturing plant is not solely determined by the quality of its machines or the skill of its workforce. It is equally dependent on the predictable, cost-effective, and timely flow of raw materials.

The Port of Montevideo exemplifies how strategic infrastructure can provide a decisive business advantage. Its combination of natural geographic benefits, favorable legal frameworks like the ‘free port’ status, and a culture of operational efficiency creates an environment where a business can focus on production instead of resolving logistical crises. For any entrepreneur or investor evaluating a location for a new solar factory, a thorough analysis of the designated import gateway is an essential part of due diligence.

Frequently Asked Questions (FAQ)

What is a ‘free port’ and why is it important for manufacturing?

A free port (or free trade zone) is a specific area within a country where goods can be imported, stored, and processed without being subject to standard customs duties and taxes. For a solar module manufacturer, this means raw materials can be stockpiled without incurring a large tax bill upfront. Taxes are typically paid only when the finished goods (solar modules) enter the domestic market. This greatly improves cash flow management.

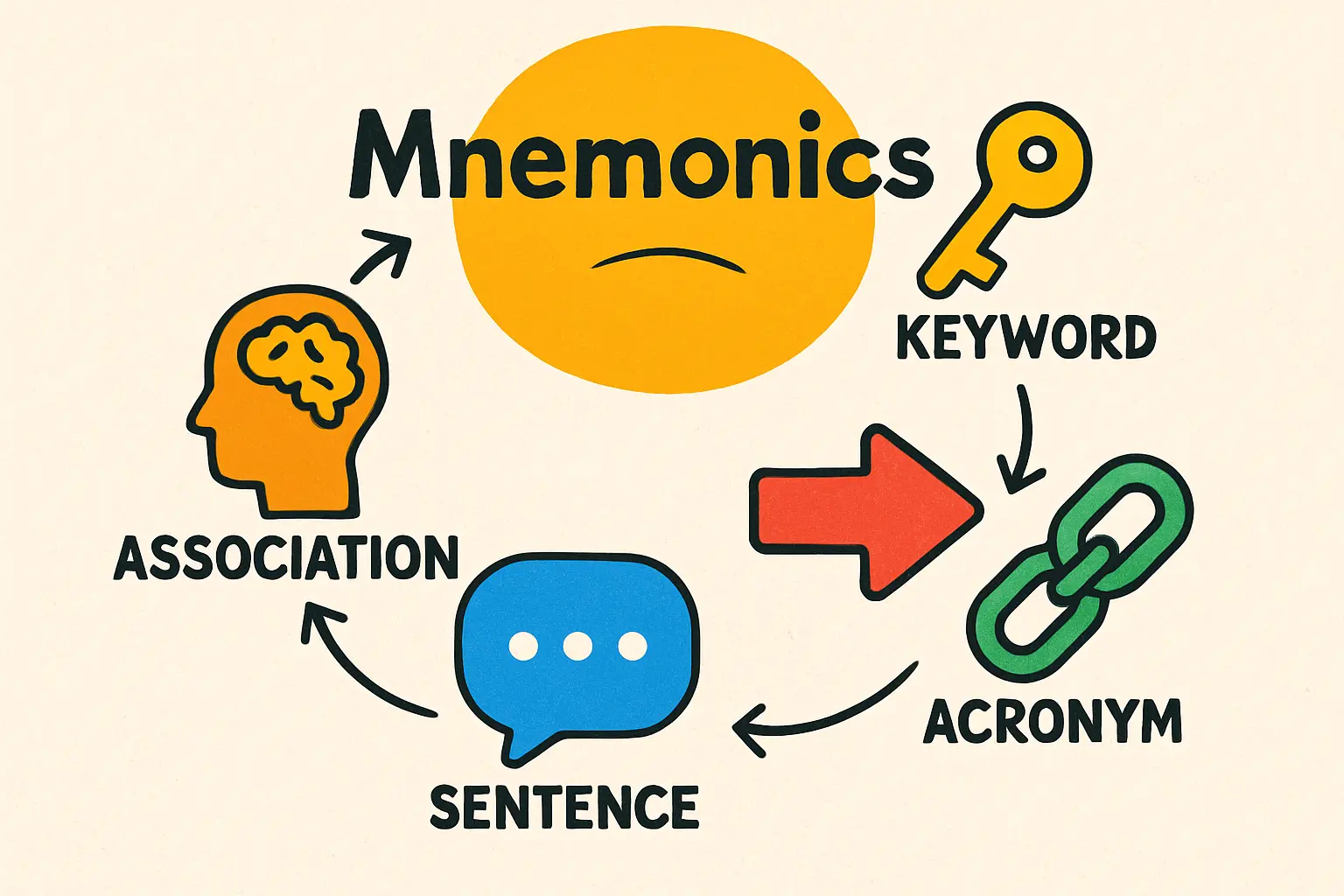

How do customs clearance procedures typically work for industrial imports?

Generally, the process involves submitting a series of documents to the customs authority before the shipment arrives. This includes the bill of lading, commercial invoice, packing list, and certificate of origin. A licensed customs broker handles this process. In an efficient system like Montevideo’s, much of this is done electronically. Once the documents are verified and any required inspections are complete, the goods are released for inland transport.

What are the main risks associated with port logistics?

The primary risks include:

- Port Congestion: Delays caused by too many ships waiting to be unloaded.

- Customs Delays: Shipments being held due to incorrect paperwork, random inspections, or bureaucratic inefficiency.

- Infrastructure Failure: Issues with cranes, storage facilities, or inland transport routes.

- Labor Strikes: Port worker strikes can halt all operations for an extended period.

- Security Risks: Theft or damage to cargo within the port or during transit.

Choosing a port with a strong track record of stability and efficiency helps mitigate these risks.

How far in advance should a manufacturer order raw materials?

Lead times depend on the supplier’s location and the shipping route. For components sourced from Asia to South America, a lead time of 60 to 90 days from order placement to arrival at the port is common. A manufacturer must factor this into inventory planning to ensure a continuous supply for the production line.