Imagine a new solar module factory in Harare, fully equipped and staffed, producing its first batch of high-quality panels. The production manager is proud of their achievement, but when the sales team approaches local distributors, they hit a roadblock: without a certificate from the Standards Association of Zimbabwe (SAZ), not a single module can be sold legally in the country.

This scenario highlights a critical step often overlooked in an initial business plan—navigating the local regulatory landscape.

For any entrepreneur planning to enter Zimbabwe’s growing solar market, understanding the mandatory SAZ certification process is not merely a technicality but a fundamental requirement for market access. This guide provides a clear, step-by-step overview of SAZ certification for locally manufactured solar modules, explaining the procedures and standards required to achieve compliance and build a trusted local brand.

Why SAZ Certification is a Non-Negotiable Requirement

In Zimbabwe, the energy sector is regulated by the Zimbabwe Energy Regulatory Authority (ZERA). To protect consumers from substandard and potentially unsafe solar products, ZERA has mandated that all solar modules and components sold in the country must be certified by the Standards Association of Zimbabwe.

This measure serves two primary business purposes:

-

Ensures Market Access: It is illegal to sell uncertified solar products in Zimbabwe. Compliance is the gateway to the entire domestic market.

-

Builds Consumer Trust: The SAZ mark acts as a seal of quality. For a new local manufacturer, it immediately differentiates their products from low-cost, unverified imports, which often suffer from premature degradation and performance issues. This certification signals to customers that the modules are safe, reliable, and perform as specified.

Understanding the Core Standard: ZWS 1018:2018

The specific standard governing crystalline silicon solar modules in Zimbabwe is ZWS 1018:2018. Business professionals without a technical background should know that this is not an arbitrary standard created in isolation.

ZWS 1018:2018 is harmonized with internationally recognized standards from the International Electrotechnical Commission (IEC):

- IEC 61215: Covers design qualification and performance.

- IEC 61730: Covers safety qualification.

This alignment is a significant advantage. It means that a factory designed to meet global best practices will already be well-positioned to satisfy SAZ requirements. The manufacturing processes and quality controls required are based on a proven international framework, providing a clear benchmark for production.

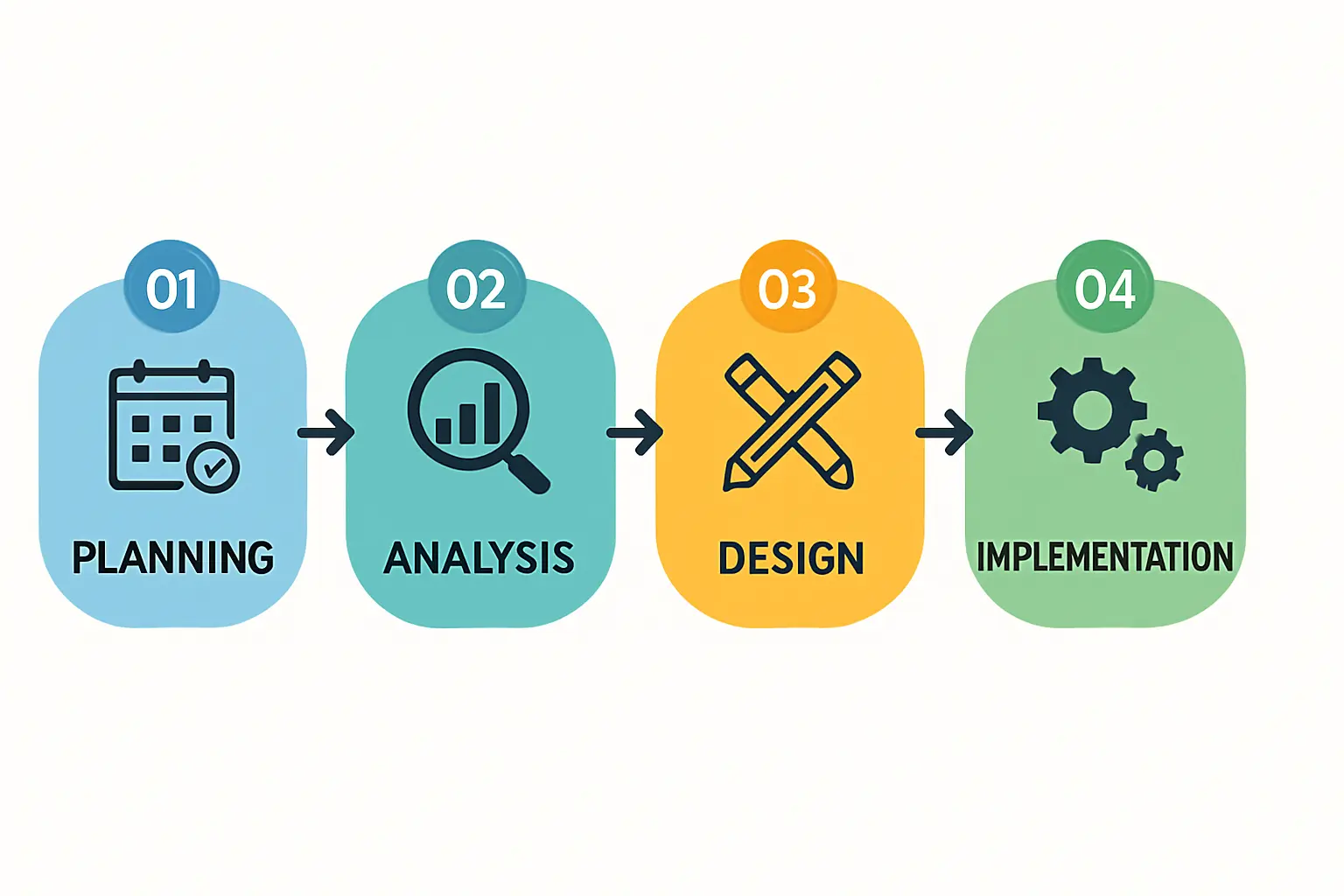

The SAZ Certification Process: A Step-by-Step Overview

Achieving SAZ certification involves a structured process of documentation, testing, and inspection. While meticulous, it’s a manageable process for a well-prepared manufacturer.

Step 1: Documentation and Application

Before physical testing begins, the manufacturer must prepare a comprehensive technical file. This file demonstrates that the product is designed and manufactured according to established quality control procedures. Key documents typically include:

- Formal Application to SAZ: The official request to initiate the certification process.

- Technical Datasheets: Detailed specifications for each module model to be certified.

- Bill of Materials (BOM): A complete list of all components used, such as solar cells, EVA encapsulant, backsheet, glass, and junction boxes.

- Quality Management System (QMS) Documentation: Proof of the internal quality control measures integrated into the complete solar panel manufacturing process.

Step 2: Sample Submission and Laboratory Testing

Once the application is accepted, SAZ will require a specified number of finished solar modules to be submitted for testing at an accredited laboratory. These tests verify both the performance and safety claims of the product.

Key tests include:

- Visual Inspection: A detailed examination for any physical defects, such as cell cracks, laminate bubbles, or frame flaws.

- Maximum Power Determination (Flash Test): Measures the module’s actual power output under standard test conditions (STC) to ensure it meets the advertised wattage.

- Insulation Test: Verifies that the module’s electrical components are properly insulated to prevent current leakage and electric shock hazards.

- Wet Leakage Current Test: Simulates rain or high-humidity conditions to ensure the module remains electrically safe, a critical test for regions with distinct rainy seasons.

Step 3: Module Marking and Labeling Requirements

The ZWS 1018:2018 standard specifies exactly what information must be permanently affixed to the back of every certified module. This label serves as the primary identifier and provides critical information for installers and end-users.

Required information includes:

- Manufacturer’s name and logo

- Module model number

- Unique serial number

- Nominal electrical characteristics (Pmax, Vmpp, Impp, Voc, Isc)

- Maximum system voltage

- The official SAZ certification mark

Step 4: Factory Audit and Assessment

In some cases, SAZ may conduct an on-site audit of the manufacturing facility. This audit verifies that the quality management systems documented in the application are being implemented consistently. Auditors inspect the production line, review quality control records, and confirm that the factory’s processes can produce modules that consistently meet the standard. This step underscores the importance of investing in a properly designed turnkey solar production line from the outset.

Practical Considerations for Entrepreneurs

Based on experience with J.v.G. turnkey projects in Southern Africa, entrepreneurs should factor several key considerations into their planning for SAZ certification. One client, Mr. Julius Etim, noted that while his factory was operationally ready, the certification process itself was a distinct project phase requiring focused management.

Timeline and Planning

Achieving first-time certification is not an overnight process. From submitting the application to receiving final approval, a manufacturer should budget approximately three to four months. This timeline can be affected by laboratory testing schedules and the completeness of the initial documentation. It’s best to begin the application process as soon as the first production-quality modules are available.

Cost Implications

The overall solar factory investment must include a budget for certification. These costs include application fees, testing fees per module type, and potential costs associated with a factory audit. Failing the initial tests can lead to repeated costs, reinforcing the need to ensure high production quality from day one.

Frequently Asked Questions (FAQ) about SAZ Certification

Is SAZ certification the same as IEC certification?

While SAZ ZWS 1018:2018 is based on IEC standards, it is a separate, mandatory national certification required for market access in Zimbabwe. An existing IEC certificate is beneficial and simplifies the process, but it does not replace the need for SAZ approval.

How long is the certification valid?

SAZ certification is typically valid for a set period, such as one to three years, after which a renewal or surveillance audit is required to ensure that quality standards are maintained.

What happens if a manufacturer sells uncertified modules?

Selling uncertified solar products is illegal and subject to enforcement actions by ZERA. Penalties can include fines, seizure of goods, and reputational damage, making compliance an essential business practice.

Conclusion: From Compliance to Competitive Advantage

For entrepreneurs entering the solar manufacturing space in Zimbabwe, SAZ certification should be viewed not as a bureaucratic hurdle but as a strategic business tool. It is the mandatory key to unlocking the domestic market and, more importantly, a powerful way to establish a brand built on quality, safety, and trust.

By understanding the requirements of ZWS 1018:2018 and integrating them into the production plan from the outset, local manufacturers can confidently meet national standards, compete effectively against unverified imports, and build a lasting reputation for excellence in Zimbabwe’s bright solar future.