Slovakia holds a remarkable and often overlooked industrial title: it is the world’s largest producer of cars per capita. For every 1,000 inhabitants, over 180 cars roll off the production lines of major global brands.

More than just an economic statistic, this number points to a deep-seated culture of high-precision manufacturing, process efficiency, and a highly skilled industrial workforce.

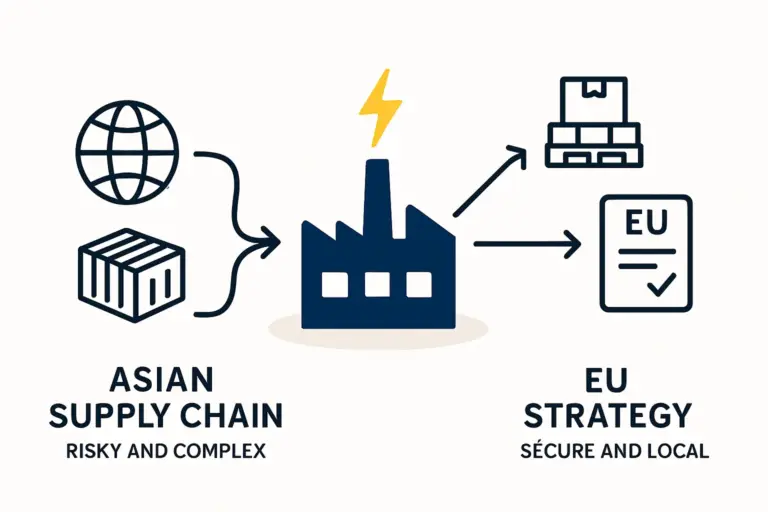

As Europe seeks to re-establish its solar manufacturing capabilities, this reservoir of automotive talent offers a strategic advantage. For the entrepreneur or business leader considering solar panel production, understanding how to leverage this existing expertise is a critical first step. This article examines the direct transferability of skills from the automotive sector to solar module assembly and outlines the focused training required to bridge the gap.

THE SYNERGY BETWEEN AUTOMOTIVE PRECISION AND SOLAR TECHNOLOGY

At first glance, building a car and assembling a solar panel may seem worlds apart. However, the underlying principles of quality control, automation, and process management are strikingly similar. The automotive industry, particularly in competitive hubs like Slovakia, has perfected a ‘zero-defect’ manufacturing culture that is directly applicable to the production of high-performance solar modules.

Far from a simple product, a modern solar module is a sophisticated electronic device engineered to perform reliably for over 25 years in harsh environmental conditions. The success of a solar panel manufacturing business plan hinges on producing these modules with exceptional consistency and quality. This is precisely where the skills honed in automotive plants become invaluable.

Transferable Skill Sets: A Competitive Edge

An employee from an automotive assembly line already has the foundational skills that are in high demand in a solar factory. The transition is less about complete retraining and more about strategic upskilling.

-

Process Discipline and Quality Control: Automotive workers are trained to follow complex, multi-step assembly instructions with meticulous attention to detail. They understand the importance of quality gates and statistical process control (SPC). That same mindset is essential in solar manufacturing, where a microscopic crack in a solar cell or a bubble in the lamination can lead to module failure years later.

-

Experience with Automation and Robotics: Modern car factories are heavily automated. Workers are accustomed to operating, monitoring, and performing basic maintenance on sophisticated robotic systems. That experience translates directly to managing automated solar equipment like cell stringers, bussing machines, and laminators. A comprehensive solar production line equipment list includes numerous machines that share operational principles with automotive automation.

-

Supply Chain and Logistics Management: The automotive industry is the benchmark for ‘just-in-time’ (JIT) manufacturing and lean logistics. Professionals with this background can efficiently manage the complex flow of materials in a solar factory—from delicate solar cells and large panes of glass to rolls of EVA encapsulant and backsheets.

FROM ASSEMBLY LINE TO CLEANROOM: THE UPSKILLING PATHWAY

While the foundational skills are strong, adapting an automotive workforce for solar module production requires specific technical knowledge. Based on experience from J.v.G. Technology GmbH turnkey projects, the training process is focused and efficient, typically lasting a few weeks rather than months.

The curriculum concentrates on a few key areas:

-

Photovoltaic (PV) Fundamentals: Workers must understand the basic principles of how a solar cell works. This context is crucial for understanding why certain handling procedures and quality standards are non-negotiable. It helps them transition from assembling mechanical parts to handling sensitive electronic components.

-

Material-Specific Handling: Training covers the correct procedures for handling fragile silicon wafers, avoiding contamination of EVA films, and managing the lamination process to ensure a perfect, void-free bond.

-

Specialized Machine Operation: While the principles of automation are familiar, operators need hands-on training on the specific functions of solar manufacturing equipment, such as programming an electroluminescence (EL) tester or operating a sun simulator for final quality assurance. Understanding how to build a solar panel factory involves learning the role of each of these specialized machines.

One entrepreneur from the region noted, ‘Our biggest concern was finding people who understood quality. We found that our best operators came from a nearby automotive supplier. They already knew how to work on a timed production line and check their own work. We just had to teach them about solar cells.’

THE BUSINESS CASE FOR SLOVAKIA AND CENTRAL EUROPE

For any business planning to enter the European solar market, the availability of a skilled and adaptable workforce significantly de-risks the investment.

-

Reduced Training Time and Costs: Leveraging the existing industrial skill base shortens the learning curve, allowing a new factory to reach target productivity and quality levels faster.

-

Established Industrial Infrastructure: Regions with a strong automotive presence, like Slovakia, typically have robust supporting infrastructure, including logistics networks, technical schools, and a pool of experienced maintenance engineers and managers.

-

Cultural Alignment with Manufacturing Excellence: The workforce inherently understands the demands of a high-volume, high-quality production environment. That cultural fit is often more difficult to build from scratch than technical skill.

The establishment of a solar module factory is not merely a technical undertaking; it is a human capital challenge. By recognizing the immense potential within Slovakia’s automotive sector, new solar ventures can build a world-class team and gain a critical competitive advantage in the revitalized European solar industry.

Frequently Asked Questions (FAQ)

-

Is a technical degree required for most solar module assembly jobs?

No. While line supervisors and quality engineers typically require technical diplomas or degrees, the majority of production line operators do not. The most important qualifications—attention to detail, the ability to follow precise instructions, and experience in a structured manufacturing environment—are common traits in the automotive workforce. -

How long does it typically take to train an experienced automotive worker for a solar production line?

For operator roles on specific machines like stringers or laminators, focused training typically takes between two to four weeks. This includes classroom instruction on PV basics and extensive hands-on training on the equipment itself until the operator can meet both quality and speed targets. -

What are the most critical roles to fill when starting a solar factory?

Beyond operators, the most critical roles are a Production Manager with experience in process optimization, a Quality Manager to establish and enforce standards, and Maintenance Technicians who can service and troubleshoot the specialized automated equipment. Often, individuals with experience in maintaining automotive robotics can be quickly trained for these maintenance roles. -

Can an existing automotive factory be repurposed for solar manufacturing?

While a direct ‘one-to-one’ repurposing is challenging due to specific requirements like cleanroom conditions for certain processes and ceiling height for lamination lines, the core building infrastructure is highly valuable. An existing automotive plant offers a robust foundation with an established power grid, loading bays, and logistical access, significantly reducing the time and cost of greenfield construction.